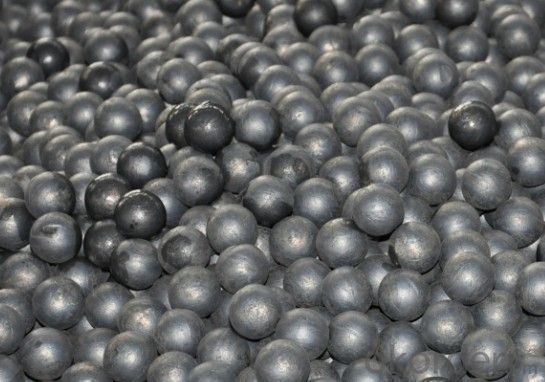

Forged Grinding Media Steel Balls With High Hardness and Resistance, Top Quality For Cement and Mine

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25MTS m.t.

- Supply Capability:

- 20000MTS/Year m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Forged Grinding Media Steel Balls With High Hardness and Resistance, Top Quality For Cement

and Mine:

1. Diameter:20mm-150mm(0.75''-6'')

2. Surface Hardness:

Forged ball:58-65HRC

Casted ball:60-65HRC

3. Material:

Forged ball: Steel

Casted ball: Iron

4. Technology: Forged & Casted ,heat treated

5. Unbreakable:0.5 Max.

6. Impact Toughness:>12

7. times of falling ball:5000 min.

8. microstructure: P+C

9. Application: gold & iron mine, steel works, cement plant and power station

10. Certificate: ISO9001:2008

Features of Forged Grinding Media Steel Balls With High Hardness and Resistance, Top Quality For Cement

and Mine:

1. High hardness

2. Good wear resistance

3. High toughness

4. No mal-roundness

Chemical Composition of Forged Grinding Media Steel Balls With High Hardness and Resistance, Top Quality For

Cement and Mine:

Name | C | Mn | Si | Cr | S | P | |||

60Mn | 0.57-0.65 | 0.70-1.0 | 0.17-0.37 | 0.25max | 0.035max | 0.035max | |||

65Mn | 0.60-0.70 | 0.90-1.2 | 0.17-0.37 | 0.25max | 0.035max | 0.035max | |||

75MnCr | 0.70-0.85 | 0.70-0.85 | 0.17-0.37 | 0.40-0.60 | 0.030max | 0.030max | |||

Specification of Grinding Media Ball | |||||||||

Nominal diameter | Diameteical Tolerance | Weight of single ball in average | Surface hardness | Impact toughness | |||||

(mm) | (mm) | (g) | (HRC) | (j/cm2 ) | |||||

Φ20 | +2 -1 | 32 |

55-65 |

≥12 | |||||

Φ25 | 64 | ||||||||

Φ30 | 110 | ||||||||

Φ40 | 263 | ||||||||

Φ50 | 513 | ||||||||

Φ60 | +3 -2 | 888 | |||||||

Φ70 | 1410 | ||||||||

Φ80 | 2104 | ||||||||

Φ90 | 2996 | ||||||||

Φ100 | 4110 | ||||||||

Φ110 | +4 -2 | 5457 | 50-60 | ||||||

Φ120 | 7102 | ||||||||

Φ130 | 9030 | ||||||||

Φ140 | +4 -3 | 11278 | |||||||

Φ150 | 13871 | ||||||||

| |||||||||

- Q: What is normalizing, annealing, tempering, quenching? What is the difference between forging parts and casting parts?

- According to the requirements of the workpiece annealing, there are many kinds of annealing process specifications, such as full annealing, spheroidizing annealing and stress relieving annealing. Steel the steel quenching is heated to the critical temperature Ac3 (hyposteel) or Ac1 (hypereutectoid steel) above a certain temperature, holding time, so that all or part of 1 Austenitic, then the cooling rate is greater than the critical cooling rate of fast cooling to below Ms (or near Ms isothermal) of martensite the body (or bainite transformation) heat treatment process. Aluminum alloys, copper alloys, titanium alloys, tempered glass and other materials are usually treated by solid solution or heat treatment with rapid cooling process. Tempering is a heat treatment process where the workpiece is hardened and heated to a temperature below AC1, which remains cool for a certain period of time and then cools to room temperature. Tempering generally followed by quenching, the purpose is: (a) to eliminate the residual stress caused by quenching, prevent deformation and cracking; (b) hardness, strength, plasticity and toughness of workpiece is adjusted, to use performance requirements; (c) the size of organization and stability, ensure the accuracy improvement; (D) and to improve the processing performance. Tempering is therefore the last important step in obtaining the desired properties of the workpiece. According to the tempering temperature range, tempering can be divided into low temperature tempering, medium temperature tempering and high temperature tempering. This answer is recommended by the questioner

- Q: The casting defects of pores, trachoma how to repair?

- Metal repair can be used to fill the repair. Airhole 2mm following LT102 recommend the use of liquid metal repairing agent.

- Q: What is the ejection angle of the die casting (Tan Gang)?

- Especially deep hole, and customers to discuss, generally take 0.3-1 degrees is enough

- Q: Why do cheap cars like stamping parts instead of casting parts?

- Separation process is also called blanking, the purpose is to make the stamping parts along a certain contour line from the sheet metal separation, at the same time guarantee the quality requirements of the separation section. Stamping is a highly efficient production methods, the use of compound die, especially the multi station progressive die stamping process can be completed in a multi machine, realized by belt uncoiling, leveling, punching, forming and finishing automatic production. High production efficiency, good working conditions, low production costs, can produce hundreds of parts per minute. The purpose of forming processes is to allow the sheet to undergo plastic deformation without breaking the billet and to make the desired shape and size. In actual production, a variety of processes are often applied to a workpiece. Blanking, bending, shearing, drawing, bulging, spinning, and straightening are the main types of stamping machines.

- Q: How to get rid of casting sand inside casting parts?

- Are you saying that in the sand casting cavity? We use the manual blast, he is like a pipe will be automatic shot out of the grit, into the casting cavity, to remove the internal cavity in the purpose of casting sand!

- Q: What is the difference between forging parts and casting parts?

- The casting parts are low in cost and short in production period. Because the molten iron has good flow properties, complex shapes can be formed. But because there may be sand holes, pores, shrinkage holes and other defects, the quality is unstable, easy to produce many defects, mechanical properties are not forged well, thus affecting the service life.

- Q: For example, casting parts contain many holes, inclusions and other defects, the size and the number of holes exceed which limit is not qualified

- For example, the castings shall be in accordance with the requirements of the second types of castings in the technical requirements for aluminum alloy castings of GB/T9438-1999;

- Q: Why do casting parts have air holes?

- First, from the source, tools, raw material drying, in the process of melting into the reaction gas, another influence is pouring process, such as high temperature solidification gas dissolved too much after not excluded. The method can adjust the pouring temperature properly, control the source of gas (drying and controlling the inoculant, especially the content of magnesium), and add cooling iron to change the solidification mode. It depends on what kind of casting you are. You can't make it clear at once. And molding sand relationship is mainly water content and permeability, brush coating resin content.

- Q: We are small castings, the need for surface treatment of shot blasting machine, about how much?

- The choice of shot blasting machine, this is according to the workpiece size, yield, whether can collision, and the working time and other factors considered, while the price of different blasting machine are not the same, but the vast majority of small castings used crawler shot blasting machine, according to the comprehensive consideration of factors such as yield, size of workpiece commonly used on the market the crawler shot blasting machine has Q324, Q326, Q328, Q3210, and each time the amount of their treatment were 125KG, 200KG, 400KG, 600KG, the specific use of what types also need to be determined according to the actual situation

- Q: How to solve casting defect casting?

- Different defects, different solutions, some shortcomings, the current domestic level can not be resolved

1. Manufacturer Overview

| Location | Shandong,China |

| Year Established | 2000 |

| Annual Output Value | US$5 Million - US$10 Million |

| Main Markets | Domestic Market, South Asia, Southern Europe, Northern Europe, Central America |

| Company Certifications | ISO9001;IS014001 Certificate |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port |

| Export Percentage | |

| No.of Employees in Trade Department | 10-20 People |

| Language Spoken: | English;Chinese; |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Grinding Balls; Grinding Rods; Grinding Cylpebs. |

| Product Price Range | Average |

Send your message to us

Forged Grinding Media Steel Balls With High Hardness and Resistance, Top Quality For Cement and Mine

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25MTS m.t.

- Supply Capability:

- 20000MTS/Year m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords