Forged Alloy Steel AISI 4140 Round Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

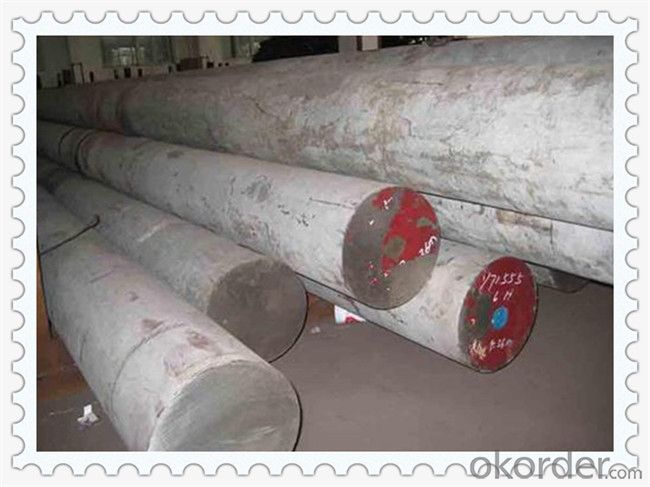

Product Description of AISI 4140 Round Bar

AISI 4140 round bar are flawless completely free from cracks and flakes, and does not contain any other imperfection,such as porosity non-metallic inclusions segregations, hard spots and residual tensions to a degree affecting their strength and durability.

| Product: | forged alloy steel AISI 4140 round bar |

| Material: | 4145, 42CrMo4, 4140, SAE8620 ,4340 etc. |

| Supplier Range: | OD.200-800mm,Weight≤20T |

| Delivery time: | 30 days after receive the deposit. |

| Produce Process: | EAF + LF + VD +(ESR) + Forged + Heat Treatment (optional) |

| Delivery condition: | Hot forged, Heat-treatment (Normalized / Annealed / Quenched / tempered), Rough machining. |

| Surface Finish: | Black, Peeled, Turned & Polished |

| Payment Term: | 30% advance by T\T; Balance pay before the shipment against shipping documents or irrevocable LC at sight |

| Technical Data: | Chemical Composition, Physical Properties and Mechanical Testing according to the customer's requirement and Standard. |

The steel is suited to applications where high surface pressures exist and friction is to be resisted as in the case of severely loaded gears, axles and pinions. It is used extensively in most industry sectors for applications requiring higher tensile strength.

Packing And Delivery

| Package | Seaworthy package (or as customer require) |

| MOQ | 1 Pieces |

| Delivery | 30 days (can be short if we have stock) |

| Payment | 30%T/T in advanced+70% balanced;irrevocable L/C at sight |

| Remarks | All-risk insurance and accept the third party test |

| Port | Tianjin/Qingdao/Shanghai |

Equipment

We are well-equipped with 2000-Ton Hydraulic press, 15-Ton Hydraulic manipulator, various kinds of Lathe and boring machine, product range OD 200mm-800mm, Length less than 9m.

- Q: Can steel round bars be used in the production of construction materials?

- Indeed, the utilization of steel round bars is feasible in the manufacturing of construction materials. Owing to their remarkable robustness and endurance, steel round bars find frequent application within the construction sector. These bars are instrumental in fortifying concrete structures, exemplified by the reinforcement of beams, columns, and slabs, thereby enhancing their resilience and steadfastness. Furthermore, in the construction of buildings and bridges, steel round bars can be employed in the creation of steel frames, trusses, and various structural constituents. The widespread popularity of these bars stems from their adaptability and capacity to endure substantial burdens in the construction industry.

- Q: What is the difference between hot rolled and cold drawn steel round bars?

- Hot rolled steel round bars are made by heating a billet or ingot of steel to a high temperature and then rolling it into the desired shape. This process results in a rougher surface finish and less precise dimensions compared to cold drawn steel round bars. Cold drawn steel round bars, on the other hand, are made by pulling a hot rolled bar through a die to achieve the desired shape and size. This process produces a smoother surface finish and more accurate dimensions. Overall, the main difference between hot rolled and cold drawn steel round bars lies in the manufacturing process and the resulting surface finish and dimensional accuracy.

- Q: Can steel round bars be used for making fuel system components?

- Yes, steel round bars can be used for making fuel system components. Steel is a common material used in the manufacturing of various fuel system components due to its strength, durability, and resistance to corrosion. Steel round bars can be machined, welded, and formed into different shapes and sizes, making them suitable for a wide range of fuel system applications. Additionally, steel's high melting point and ability to withstand high pressure and temperature conditions make it a reliable choice for fuel system components that are exposed to extreme conditions.

- Q: Can steel round bars be hardened or tempered?

- Yes, steel round bars can be hardened or tempered.

- Q: How do steel round bars compare to glass round bars?

- Steel round bars are significantly stronger and more durable compared to glass round bars. Steel is a metallic material that offers high tensile strength and can withstand heavy loads, making it suitable for structural applications. On the other hand, glass round bars are more fragile and prone to breakage under stress. However, glass round bars have a more aesthetic appeal and are commonly used in decorative applications. The choice between steel and glass round bars depends on the specific requirements of the project, with steel being preferred for strength and glass for its visual qualities.

- Q: Can steel round bars be hardened and tempered?

- Yes, it is possible to harden and temper steel round bars. Hardening and tempering are heat treatments that can enhance the hardness and strength of steel. To harden a steel round bar, it must be heated to a high temperature and then rapidly cooled, typically through quenching in water, oil, or air. This procedure alters the steel's structure, resulting in increased hardness and brittleness. However, the hardened steel round bar may be too brittle for many applications. To address this issue and improve its toughness, the hardened steel is subjected to tempering. Tempering entails reheating the steel to a specific temperature and holding it at that temperature for a designated period before allowing it to cool naturally. This process enables the steel to partially soften and alleviate internal stresses, thereby enhancing toughness and ductility. The hardness and tempering temperature can be adjusted to achieve desired mechanical properties for various applications. By employing the hardening and tempering process, steel round bars with different levels of hardness, strength, and toughness can be produced to meet specific engineering requirements.

- Q: What is the difference between a cold finished and a turned steel round bar?

- A cold finished steel round bar is processed through cold drawing or cold rolling processes, resulting in a smoother and more precise surface finish. On the other hand, a turned steel round bar is machined on a lathe, which removes material to achieve the desired dimensions and surface finish. Overall, the difference lies in the manufacturing process and the resulting surface finish of the two types of steel round bars.

- Q: What are the advantages of using magnesium-alloy steel round bars?

- One advantage of using magnesium-alloy steel round bars is their high strength-to-weight ratio. These bars offer excellent strength and durability while being lightweight, making them suitable for applications where weight reduction is crucial, such as in aerospace and automotive industries. Furthermore, magnesium-alloy steel round bars exhibit good corrosion resistance, which extends their lifespan and makes them ideal for outdoor and marine applications. Additionally, these bars can be easily machined and formed, allowing for flexibility in design and fabrication processes.

- Q: What are the specifications and standards for steel round bars?

- The specifications and standards for steel round bars vary depending on their intended use and industry requirements. However, there are general specifications and standards that apply to most steel round bars. To start, the dimensions of steel round bars are typically specified in terms of diameter, length, and tolerance levels. The diameter can range from a few millimeters to several inches, while the length can vary according to customer needs. Tolerance levels indicate the allowable deviation from the specified dimensions, ensuring the bars meet desired accuracy and consistency. In terms of material composition, steel round bars are predominantly made from carbon steel, alloy steel, or stainless steel. The specific grade and composition depend on the application, such as structural, construction, automotive, or aerospace. These grades are established by organizations like ASTM or ISO, which define the chemical composition, mechanical properties, and other characteristics of the steel. Steel round bars must meet certain standards for mechanical properties to ensure their strength, ductility, and resilience. These properties include tensile strength, yield strength, elongation, hardness, impact resistance, and more. Relevant organizations like ASTM or ISO specify the standards for these properties, providing guidelines for manufacturers and users to ensure the bars are suitable for their intended applications. Surface finish is another important aspect of steel round bars. Standard surface finish options include black, peeled, ground, polished, or chrome-plated, among others. These finishes impact appearance, corrosion resistance, and ability to withstand wear and tear. Additionally, steel round bars may need to adhere to specific standards for heat treatment, such as annealing, quenching, or tempering, to enhance their mechanical properties or improve machinability. Overall, the specifications and standards for steel round bars cover dimensions, material composition, mechanical properties, surface finish, and heat treatment requirements. These standards ensure that steel round bars meet necessary quality, performance, and safety criteria for their designated applications. Manufacturers, suppliers, and end-users must be aware of these specifications and standards to select and use steel round bars appropriately.

- Q: Are steel round bars available in different lengths?

- Indeed, there is a variety of lengths for steel round bars. These bars are designed in diverse lengths to cater to various needs and applications. The range of lengths may differ depending on the supplier or manufacturer. Typically, steel round bars are commonly available in lengths between 6 and 12 feet. However, it is also possible to acquire custom lengths through special requests. This wide range of options grants more flexibility in construction and fabrication projects, as it facilitates the ability to cut or modify the bars according to specific requirements.

Send your message to us

Forged Alloy Steel AISI 4140 Round Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords