Flinty Aluminum Alloy Grooved Drumof Textile Machine Parts

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 12000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications:

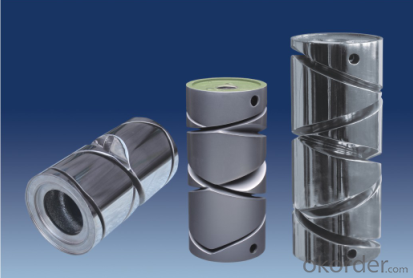

Flinty Aluminum Alloy Grooved Drumof Textile Machine Parts

Adavantages:

Flinty Aluminum Alloy Grooved Drumof Textile Machine Parts has the following advantages:

Best groove curve, ultra-fine processing, and high smooth finish(Ra<0.2μm).

Highly accurate, mass-radius product is less than 10g·mm, and the linear velocity can reach 2000m/s.

High wear resistance, corrosion resistance.

Coating has high density,small crystallization , low porosity.

Product Description:

Pictures shows of Flinty Aluminum Alloy Grooved Drumof Textile Machine Parts:

Models of Flinty Aluminum Alloy Grooved Drumof Textile Machine Parts:

Model | Groove number of turns | Lead | Aperture | Outer diameter | Length | Package angle |

CT-B | 2.5 | 154 | φ20 | φ82 | 176 | 0° |

CT-S | 2.5 | 147 | φ20 | φ82 | 183 | 0° |

CT-S1 | 2 | 150 | φ20 | φ95 | 176 | 0°—3°30′ |

CT-J | 2.5 | 152 | φ20 | φ82 | 176 | 3°30′—5°57′ |

Ps: CT-grooved drum, B-used in assembly winder, S-slack winding, J-conical cylinder, Z-gooved drum of atomatic winder, L-roller, M-friction drum

Packaging & Delivery of Flinty Aluminum Alloy Grooved Drumof Textile Machine Parts:

Packaging Detail: Wooden case or as per customers' requirements

Delivery Detail: 5 days from receiving the advance payment

FAQ of Flinty Aluminum Alloy Grooved Drumof Textile Machine Parts:

· Q:What is the machine used for?

A:Flinty Aluminum Alloy Grooved Drumof Textile Machine Parts is suitable for processing PP, PE split film yarn/ just twine, cotton twine, weaved twine to ball.

· Q: What is the MOQ?

A: 100 pc.

· Q: What is the lead time of the product?

A: 5-20 days after payment

- Q: Why the first industrial revolution in the cotton textile industry innovation will cause the British national yarn shortage?

- The emergence of a large number of free labor force has contributed to the rapid development of the British factory art industry at that time. At the same time, because the textile industry itself has less investment, quick, high profit characteristics, so it became the backbone of the workshop industry. In this way, the first industrial revolution of the situation will be the first in the textile industry in the rise of handicrafts

- Q: What are the general fixed assets of the textile industry?

- Spinning equipment, chemical fiber machinery, vinylon equipment, Wei Lun short wire spinning machine

- Q: What is the current status of the textile industry?

- China's textile enterprises should overcome the difficulties of rising raw materials, appreciation of the renminbi and export tax rebates, seize the opportunities for the development of the textile industry, improve the concentration of the industry, curb the blind expansion of inefficient production capacity, increase the construction of special industrial parks, strengthen independent innovation The pace of China's textile industry to enhance the brand building, industrial restructuring and upgrading. So that China by the textile power to the textile power forward.

- Q: When did Chinese ancient textile technology come from? Why does Europe call China "silk country"?

- Indicating that more than 3400 years ago, our people have mastered the bark fiber degumming technology. These linen textile level has been equivalent to more than a thousand years after the Western Han Dynasty maw heap of the tomb of linen

- Q: What is the history of the development of textile machinery?

- 1779 British S. Crompton (Samuel Crompton) invented the spinning machine. After the introduction of the United States, 1828 American J. Thorpe invented the ring spinning machine, due to the use of continuous spinning to improve productivity several times.

- Q: Who invented Jenny spinning machine?

- He suddenly thought: if a few spindles are arranged vertically, with a spinning wheel driven, not all of a sudden spinning more yarn it? Hargreaves was very excited and tried to do it right away. In the following year he made a new spinning machine with eight spinning spindles with a spinning wheel, and the effect was eight times higher. 1764 made to his daughter Jenny named spinning machine. This is the first multi-spindle hand spinning machine, equipped with eight spindles, with a roller feed fiber strip, suitable for cotton, wool, hemp fiber spinning. The emergence of Jenny's spinning machine caused a lot of hand-spinning spurs at the time, and they rushed into the home of Hargreaves to destroy the machine.

- Q: What is the cashmere dyeing process?

- Spinning the best equipment is the Italian equipment, and now a lot of small manufacturers useful in Japan, there are some domestic modified, the Italian equipment of each of more than 1200 million RMB

- Q: What is the task of preparing the process before spinning?

- The pressed raw cotton was loosened to about 0.1 mg of cotton

- Q: What is the historical background of the mechanization of the British cotton textile industry?

- Labor force: enclosure movement and guild organization earlier disintegration, provided labor resources;

- Q: China's textile industry prospects of printing and dyeing ?

- Prospective Industry Research Institute Textile Machinery Manufacturing Industry Research Group, said the world's leading textile machinery enterprises in China have invested and set up factories in China, the scale of production in China has reached the Chinese textile machinery production 1/3.

Send your message to us

Flinty Aluminum Alloy Grooved Drumof Textile Machine Parts

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 12000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords