Aluminum Alloy Grooved Drum of Winding Machine Parts

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 12000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications:

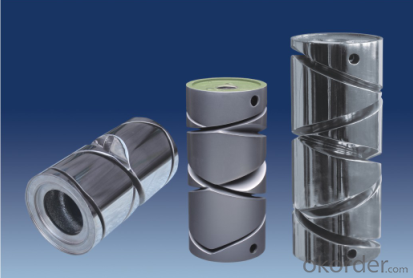

Aluminum Alloy Grooved Drum of Winding Machine Parts

Adavantages:

Aluminum Alloy Grooved Drum of Winding Machine Parts has the following advantages:

Best groove curve, ultra-fine processing, and high smooth finish(Ra<0.2μm).

Highly accurate, mass-radius product is less than 10g·mm, and the linear velocity can reach 2000m/s.

High wear resistance, corrosion resistance.

Coating has high density,small crystallization , low porosity.

Product Description:

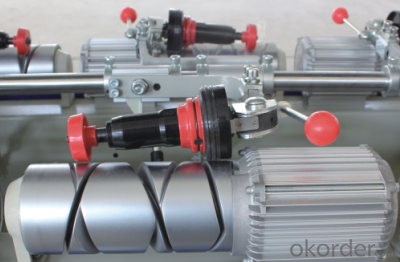

Pictures shows of Aluminum Alloy Grooved Drum of Winding Machine Parts:

Models of Aluminum Alloy Grooved Drum of Winding Machine Parts:

Model | Groove number of turns | Lead | Aperture | Outer diameter | Length | Package angle |

CT-B | 2.5 | 154 | φ20 | φ82 | 176 | 0° |

CT-S | 2.5 | 147 | φ20 | φ82 | 183 | 0° |

CT-S1 | 2 | 150 | φ20 | φ95 | 176 | 0°—3°30′ |

CT-J | 2.5 | 152 | φ20 | φ82 | 176 | 3°30′—5°57′ |

Ps: CT-grooved drum, B-used in assembly winder, S-slack winding, J-conical cylinder, Z-gooved drum of atomatic winder, L-roller, M-friction drum

Packaging & Delivery of Aluminum Alloy Grooved Drum of Winding Machine Parts:

Packaging Detail: Wooden case or as per customers' requirements

Delivery Detail: 5 days from receiving the advance payment

FAQ of Aluminum Alloy Grooved Drum of Winding Machine Parts:

· Q:What is the machine used for?

A:Aluminum Alloy Grooved Drum of Winding Machine Parts is suitable for processing PP, PE split film yarn/ just twine, cotton twine, weaved twine to ball.

· Q: What is the MOQ?

A: 100 pc.

· Q: What is the lead time of the product?

A: 5-20 days after payment

- Q: What is spinning down?

- According to archaeological data, in the whole of China dozens of provinces and cities have been excavated in the early residents of the site, almost all the major parts of the spinning spindles unearthed

- Q: What is a spinning wheel?

- Hand spinning the image data in the unearthed folk artifacts in the Han Dynasty repeatedly found that hand-spinning spinning machine as early as the Han Dynasty has been very popular

- Q: Textile machinery industry how to have prospects?

- Foreign-funded enterprises in addition to the equipment for the Chinese market, but also a large number of exports, and even anti-sales back to the country of origin. China is moving from one of the largest textile machinery market demand to Asia Textile Machinery Manufacturing Center, and even the world textile machinery manufacturing center.

- Q: What is the current status of the textile industry?

- From the international environment, the international market is still a large expansion of space and opportunities. With the end of 2007, China and the EU textile limit expires, the end of 2008 the end of the Sino-US textile quota limit, the Chinese textile quota era is approaching, accounting for more than 60% of the global textile market share area is fully open, will bring to China's textile trade Great opportunity. And the next few years the world economy will remain in the rising range, will promote the growth of international trade, which will give China's textile and garment exports to bring favorable international market protection.

- Q: What is the difference between yarn spinning and ring spinning?

- Ring spinning (combing) Process: clear flowers - carding - pre-parallel - articles and rolls - combing - the first road parallel - two parallel - roving - spinning - Winding

- Q: What are the different effects of textile equipment?

- , Low technology content, the process of redundant, such as cotton, to experience spinning, weaving

- Q: Textile equipment to protect the work is not a special type of work?

- , In accordance with the current social insurance policy, special types of early retirement must also have four conditions: First, engaged in special types of work must be the former Ministry of Labor and the central authorities approved the special types of work, different industries between the special types of work Can not match each other. Second, must be in the original state-owned, collective enterprises engaged in high-altitude and particularly heavy manual labor accumulated over 10 years; engaged in underground, high temperature work accumulated over 9 years; engaged in other toxic and harmful work accumulated over 8 years. Third, the staff file on its special trades experience in the original record. Four men over 55 years of age, women over 45 years of age, and the cumulative payment of 15 years of years.

- Q: How is the machine automatically connected to the machine?

- The machine is adapted to 1100mm to 2300mm amplitude of the machine access, the knotting speed of 200-350 head / min, 5-10 times higher than the artificial joint efficiency

- Q: What is the cashmere dyeing process?

- The effect of dyeing on the quality and cost of woolen cashmere yarns The relationship between dyeing cost and dyeing cost is very small. When the fiber is dark, the fiber strength decreases and the spinning consumption increases. Heavy role

- Q: What are the mechanical characteristics of textile machinery?

- A major development feature of modern textile machinery is to continuously improve the speed of the machine, resulting in high yield, to reduce the number of equipment, reduce plant area, save investment and labor, with less money to achieve greater results. Table 1, Table 2, Table 3, the figures show the trend of high-speed textile machinery.

Send your message to us

Aluminum Alloy Grooved Drum of Winding Machine Parts

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 12000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords