Ceramic Coated Groove Drum of Textile Machine Parts

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 12000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications:

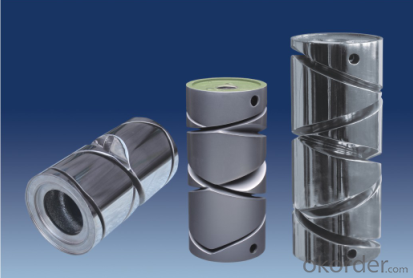

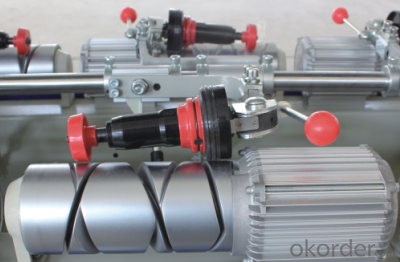

Ceramic Coated Groove Drum for High Speed Cone Winder

Adavantages:

Ceramic Coated Groove Drum has the following advantages:

Best groove curve,ultra-fine processing,mirror polished surface, and high smooth finish(Ra<0.4μm).

We plating Cr on the surface, the hardness of the surface is higher than HV900. High wear resistance, static elimination, less hairiness and surface inferior smooth processing.

The dynamic balance of our grooved drums are highly accurate, perform reliably,the linear velocity can reach 1200m/s.

Light weight and energy saving.

No running-in period, high quality in winding, perfect forming.

Product Description:

Pictures shows of Ceramic Coated Groove Drum:

Models of High Quality Metal Grooved Drum:

Model | Groove number of turns | Lead | Aperture | Outer diameter | Length | Package angle |

CT-B | 2.5 | 154 | φ20 | φ82 | 176 | 0° |

CT-S | 2.5 | 147 | φ20 | φ82 | 183 | 0° |

CT-S1 | 2 | 150 | φ20 | φ95 | 176 | 0°—3°30′ |

CT-J | 2.5 | 152 | φ20 | φ82 | 176 | 3°30′—5°57′ |

Ps: CT-grooved drum, B-used in assembly winder, S-slack winding, J-conical cylinder, Z-gooved drum of atomatic winder, L-roller, M-friction drum

FAQ of Yarn Winding Machine:

1. Q:What is the machine used for?

A:Vertical Soft Yarn Winder is suitable for processing PP, PE split film yarn/ just twine, cotton twine, weaved twine to ball.

2. Q: What is the MOQ?

A: 100 pc.

?3. Q: What is the lead time of the product?

A: 5-20 days after payment

- Q: Why the first industrial revolution in the cotton textile industry innovation will cause the British national yarn shortage?

- Since the invention of the shuttle, people have been committed to the development of new textile machinery, unfortunately, progress has been unhappy. The gift of science is prepared for those who are prepared.

- Q: How does the mechanical wave generated in the spinning process work?

- But in some places meet the vibration to strengthen, in some places vibration weakened.

- Q: Textile machinery industry how to have prospects?

- In the textile industry, driven by China's textile machinery manufacturing industry to achieve a lengthy development. At present, China's textile machinery manufacturing industry has become a complete range, to meet the needs of the textile industry, with independent research and development capacity of the pillar industries.

- Q: What is the difference between yarn spinning and ring spinning?

- Air spinning without spindle, mainly by the carding roller, spinning cup, false twist device and other components. The carding roller is used to grasp and card the fed sliver fiber, and the centrifugal force produced by his high-speed rotation can throw the captured fiber. Spinning cup is a small metal cup, his rotation speed than the carding roller more than 10 times higher, resulting in the centrifugal effect, the cup of air to the row;

- Q: What are the main producing areas of Chinese textile machinery?

- While the southern Jiangsu and Zhejiang, mainly textile mills more, but there are many textile machinery manufacturers

- Q: Is there a textile industry in the Qin Dynasty?

- Until today, our daily clothing, certain daily necessities and works of art are the products of textile and printing and dyeing technology.

- Q: How is the machine automatically connected to the machine?

- The machine is adapted to 1100mm to 2300mm amplitude of the machine access, the knotting speed of 200-350 head / min, 5-10 times higher than the artificial joint efficiency

- Q: What are the risks of safety accidents in the textile machinery industry?

- Textile machinery industry is the light industry, mainly to master with high-speed rotating machine production

- Q: Why did the first industrial revolution begin with the sign of Jenny's textile machine rather than shuttle?

- The innovation of the British cotton industry began in 1733 when the mechanic John Kay found that the shuttle was the sign of the industrial revolution, but was narrow and limited to light industry.

- Q: Textile machinery production process is probably what kind of?

- Textile machinery is a very broad concept, including a lot of machinery, a carding machinery, spinning machinery, weaving machinery and so on.

Send your message to us

Ceramic Coated Groove Drum of Textile Machine Parts

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 12000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches