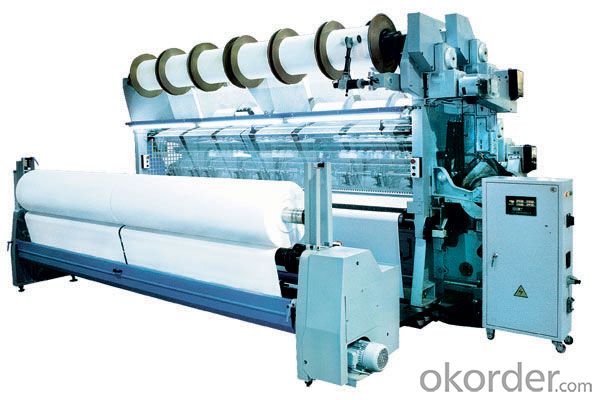

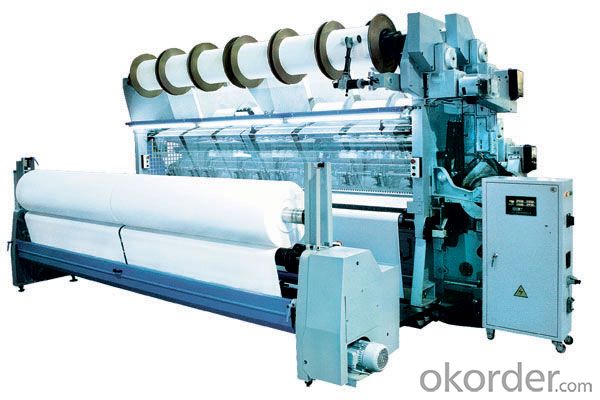

TERRY WARP KNITTING MACHINE GE272 SERIES

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Usingpolyamide fibre,polyester filament fibre,cotton yarn and fine fibre forknitting one-sided terry fabric.

Application:

Using polyamide fibre,polyester filament fibre,cotton yarnand fine fibre for knitting one-sided terry fabric and double-sided terryfabric such as towel,bath towel,bathrobe,towel quilt,dish toweletc。In case of shearing and raising the long loop,it can also bemade into cotton blanket etc.Due to being fasted With the

stitch of base cloth,the terry is flat and smooth,and hardlycomes out of base cloth.

Technical date sheet

MAIN TECHNICAL SPECIFICATIONS: | ||

Model | GE272SM | GE272SP |

Needle | Compound needle | |

Working Width | 3454mm(136”) 5255mm(186”) | |

Gauge | E24,E26,E28 | |

Knitting Speed(MAX.) | 750rpm(136”) 750rpm(136”) 1300rpm(186”) 1300rpm(186”Chemical fibre) | |

Height of Terry | L1:4mm(MAX.) L4:6mm(MAX.) | 2mm or 3mm |

Number of Guide Bars | 4 guide bars(2 ground bars,2 terry bars) | 3 guide bars &1sinker bar |

Characteristics | The shog are under control of 6 tracks of pattern wheel.Fixed with a conversion device between terry loop and plain stitch. | 。 With an additional device,it can knit double terry fabric. |

Density Range | 6.18~70.4courses/cm | |

Power | (Main motor):5.5KW(136”); 9KW(186”) (Inching motor):0.75KW (Batching motor):1.5KW | |

Beams | φ535mmX535mm(φ21”X21”) orφ762mm X535mm(φ30”X21”) | |

Weight(Kg) | 8000 | |

- Q: What is spinning down?

- Unearthed early spinning wheel, generally by the stone or pottery by a simple polished, the shape is different, mostly drum-shaped, round, flat round, quadrilateral and other like, and some tread also painted decoration.

- Q: What is a spinning wheel?

- While the pedal spinning wheel drive the power of the spinning wheel from the foot, the operation, the spinning woman can use both hands for spinning operation, greatly improving the work efficiency. Since its inception, spinning gear has been the most popular spinning machine, even in modern times, some remote areas still use it as the main spinning tool.

- Q: What are the high efficiency of the spinning machine and the Jenny spinning machine of the invention?

- The earliest use of hydraulic spinning machine is horsepower driven, and later cited hydraulic. The use of hydraulically operated machines is of great importance in the history of the textile industry, where textile workers can operate the machine at hand, but once the power is used, the worker can not leave the power source, As the beginning of the factory system. The first batch of factories in history was established to make textiles. In 1779, S. Crompton, in conjunction with the advantages of the Jenny spinning machine and the hydro spinning machine, developed a spinning mule that spun out fine and strong spun yarns,

- Q: The state of the textile industry machinery revitalization, expanding domestic demand, the specific policy is what?

- Textile machinery is the production of textile industry and material basis, its technical level, quality and manufacturing costs, is directly related to the development of the textile industry. In recent years, China's textile machinery industry is developing very rapidly.

- Q: What is a large hydraulic spinning wheel?

- Song and Yuan Dynasties, with the socio-economic development, in a variety of transmission machine on the basis of spinning, and gradually produced a dozens of spindle spindle

- Q: What are the different effects of textile equipment?

- , Low technology content, the process of redundant, such as cotton, to experience spinning, weaving

- Q: Is there a textile industry in the Qin Dynasty?

- Han labor people is the first invention and mass production of silk use of the nation, the production of silk products is to open the world's first large-scale East-West trade exchanges, known as the "Silk Road."

- Q: Who invented Jenny spinning machine?

- Things start from the day of 1764. England Lancashire has a textile worker James Hargreaves, that night he went home, opened the door after accidentally kicked his wife is using the spinning machine, when his first reaction is to hurry Spinning machine righting. But when he bent down, but suddenly shocked, and he saw that the spinning was spinning the spinning machine is still turning, but the original sideways of the yarn now become upright.

- Q: Is the textile machine made of those accessories?

- This part mainly includes the decapitating device, which is some sensor, used to detect the fault; transmission mechanism, used to transmit power; brake device,

- Q: What are the classification of textile machinery?

- 5. Modern textile machinery:

Send your message to us

TERRY WARP KNITTING MACHINE GE272 SERIES

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords