Hard Al-alloy Grooved Drum of Textile Machinery Parts

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 12000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications:

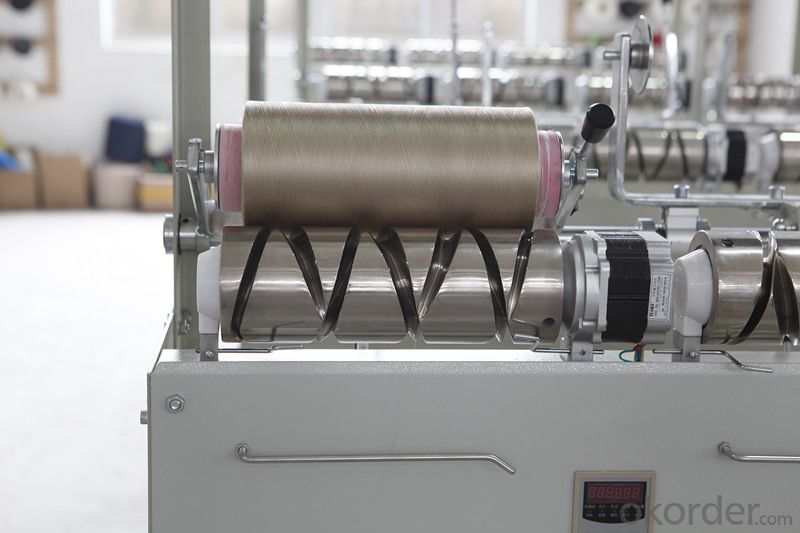

Hard Al-alloy Grooved Drum of Textile Machinery Parts

Adavantages:

1. Best groove curve,ultra-fine processing,mirror polished surface, and high smooth finish(Ra<0.4μm).

2. We plating Cr on the surface, the hardness of the surface is higher than HV900. High wear resistance, static elimination, less hairiness and surface inferior smooth processing.

3. The dynamic balance of our grooved drums are highly accurate, perform reliably,the linear velocity can reach 1200m/s.

4. Light weight and energy saving.

5. No running-in period, high quality in winding, perfect forming.

Product Description:

Pictures shows of Hard Al-alloy Grooved Drum of Textile Machinery Parts :

Models of Hard Al-alloy Grooved Drum of Textile Machinery Parts :

Model | Groove number of turns | Lead | Aperture | Outer diameter | Length | Package angle |

CT-B | 2.5 | 154 | φ20 | φ82 | 176 | 0° |

CT-S | 2.5 | 147 | φ20 | φ82 | 183 | 0° |

CT-S1 | 2 | 150 | φ20 | φ95 | 176 | 0°—3°30′ |

CT-J | 2.5 | 152 | φ20 | φ82 | 176 | 3°30′—5°57′ |

Ps: CT-grooved drum, B-used in assembly winder, S-slack winding, J-conical cylinder, Z-gooved drum of atomatic winder, L-roller, M-friction drum

Packaging & Delivery of Hard Al-alloy Grooved Drum of Textile Machinery Parts :

Packaging Detail: Wooden case or as per customers' requirements

Delivery Detail: 5 days from receiving the advance payment

FAQ of Hard Al-alloy Grooved Drum of Textile Machinery Parts :

· Q:What is the machine used for?

A:Hard Al-alloy Grooved Drum of Textile Machinery Parts is suitable for processing PP, PE split film yarn/ just twine, cotton twine, weaved twine to ball.

· Q: What is the MOQ?

A: 100 pc.

· Q: What is the lead time of the product?

A: 5-20 days after payment

- Q: What are the high efficiency of the spinning machine and the Jenny spinning machine of the invention?

- The emergence of the multi-spindle spinning car, the development of handmade textile machinery to the peak, the manual spinning industry, the multi-spindle spinning machine is to enhance the efficiency of the most complete, the fastest spinning wheel. 5. Spinning mechanization Until the emergence of the industrial revolution, the rapid growth of the market, the demand for production increased after the emergence of new spinning technology.

- Q: The state of the textile industry machinery revitalization, expanding domestic demand, the specific policy is what?

- Textile machinery is the production of textile industry and material basis, its technical level, quality and manufacturing costs, is directly related to the development of the textile industry. In recent years, China's textile machinery industry is developing very rapidly.

- Q: What is a large hydraulic spinning wheel?

- Large spinning wheel and the original spinning wheel is different, its characteristics are: the number of spindle up to dozens of pieces, and the use of hydraulic drive. These characteristics make the big spinning wheel equipped with the prototype of modern spinning machinery, to adapt to large-scale specialized production

- Q: Textile machinery industry how to have prospects?

- Prospective Industry Research Institute Textile Machinery Manufacturing Industry Research Group, said the world's leading textile machinery enterprises in China have invested and set up factories in China, the scale of production in China has reached the Chinese textile machinery production 1/3.

- Q: What are the risks of safety accidents in the textile machinery industry?

- Second, the safety of workers is not in place. Machine old, do not attach importance, do not update.

- Q: What are the related fields of textile engineering?

- 1. Master the basic theory of textile engineering disciplines, basic knowledge;

- Q: Why did the first industrial revolution begin with the sign of Jenny's textile machine rather than shuttle?

- The innovation of the British cotton industry began in 1733 when the mechanic John Kay found that the shuttle was the sign of the industrial revolution, but was narrow and limited to light industry.

- Q: What is the task of preparing the process before spinning?

- The pressed raw cotton was loosened to about 0.1 mg of cotton

- Q: What is the structure and working principle of Jenny's spinning machine?

- The yarn is hooked by the spindle bar was held, the small car on the platen also holds the yarn, spinning rotation wheel to drive the shaft, shaft through the rope rotation spindle, which is the yarn Twist the process. Push the car forward is a stretch process.

- Q: China's textile industry prospects of printing and dyeing ?

- From a global perspective, the past, textile machinery manufacturing competition is mainly concentrated in Germany, Italy, Switzerland and other textile machinery production power. But in recent years, driven by domestic and Asian market demand, China's textile machinery manufacturing industry continues to expand, China has become the world's largest textile machinery manufacturing country.

Send your message to us

Hard Al-alloy Grooved Drum of Textile Machinery Parts

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 12000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords