Textiles Winder Drums of Winding Machine Parts

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 12000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications:

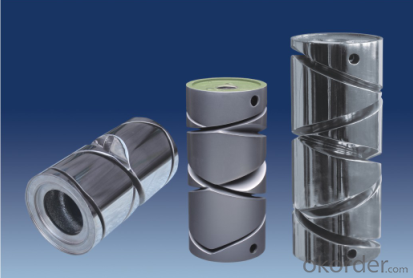

Textiles Winder Drums of Winding Machine Parts

Adavantages:

Textiles Winder Drums of Winding Machine Parts has the following advantages:

Best groove curve, ultra-fine processing, and high smooth finish(Ra<0.2μm).

Highly accurate, mass-radius product is less than 10g·mm, and the linear velocity can reach 2000m/s.

High wear resistance, corrosion resistance.

Coating has high density,small crystallization , low porosity.

Product Description:

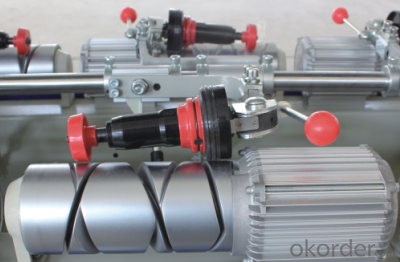

Pictures shows of Textiles Winder Drums of Winding Machine Parts:

Models of Textiles Winder Drums of Winding Machine Parts:

Model | Groove number of turns | Lead | Aperture | Outer diameter | Length | Package angle |

CT-B | 2.5 | 154 | φ20 | φ82 | 176 | 0° |

CT-S | 2.5 | 147 | φ20 | φ82 | 183 | 0° |

CT-S1 | 2 | 150 | φ20 | φ95 | 176 | 0°—3°30′ |

CT-J | 2.5 | 152 | φ20 | φ82 | 176 | 3°30′—5°57′ |

Ps: CT-grooved drum, B-used in assembly winder, S-slack winding, J-conical cylinder, Z-gooved drum of atomatic winder, L-roller, M-friction drum

Packaging & Delivery of Textiles Winder Drums of Winding Machine Parts:

Packaging Detail: Wooden case or as per customers' requirements

Delivery Detail: 5 days from receiving the advance payment

FAQ of Textiles Winder Drums of Winding Machine Parts:

· Q:What is the machine used for?

A:Textiles Winder Drums of Winding Machine Parts is suitable for processing PP, PE split film yarn/ just twine, cotton twine, weaved twine to ball.

· Q: What is the MOQ?

A: 100 pc.

· Q: What is the lead time of the product?

A: 5-20 days after payment

- Q: How does the mechanical wave generated in the spinning process work?

- The sum bar means that the two columns are superimposed on each other

- Q: What is a large hydraulic spinning wheel?

- Song and Yuan Dynasties, with the socio-economic development, in a variety of transmission machine on the basis of spinning, and gradually produced a dozens of spindle spindle

- Q: What is the chenille mechanical principle?

- The machine's domestic model is in the digestion and absorption of foreign exhibitors on the basis of the prototype, after the transplant, redesigned and manufactured

- Q: What are the related fields of textile engineering?

- Business training requirements: The students mainly learn the basic theory of textile engineering and basic knowledge, by the textile design, textile technology design and other aspects of basic training, with textile production and management of the basic ability.

- Q: What is the task of preparing the process before spinning?

- Clear mixed in the raw cotton acrobatics and neps, impurity removal rate of 40% to 70%

- Q: What is the textile process?

- Weaving process mainly include: winding, warping, sizing, through, weaving, finishing.

- Q: What are the classification of textile machinery?

- 2. Spinning wheel

- Q: Textile machinery production process is probably what kind of?

- And then the processing of a good machine frame is the initial installation of the wall after the installation (here first to do the foundation).

- Q: What is the historical background of the mechanization of the British cotton textile industry?

- Technology: Accumulation of workshop handicraft technology;

- Q: China's textile industry prospects of printing and dyeing ?

- As of the end of 2010, the industry total assets reached 77.613 billion yuan, an increase of 27.78%; industry sales revenue 815.65 billion yuan, an increase of 42.13%. Overall, after experiencing the decline in industry growth in 2008, the industry scale expansion rate significantly accelerated, the overall development trend is good.

Send your message to us

Textiles Winder Drums of Winding Machine Parts

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 12000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords