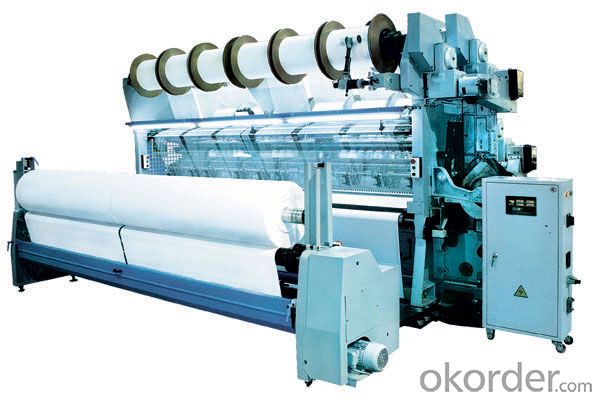

TERRY WARP KNITTING MACHINE GE272S SERIES

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

APPLICATION:

Using polyamide fibre,polyester filament fibre,cotton yarnand fine fibre for knitting one-sided terry fabric and double-sided terryfabric such as towel,bath towel,bathrobe,towel quilt,dish toweletc。In case of shearing and raising the long loop,it can also bemade into cotton blanket etc.Due to being fasted With the

stitch of base cloth,the terry is flat and smooth,and hardlycomes out of base cloth.

TECHNICAL DATA SHEET

MAIN TECHNICAL SPECIFICATIONS: | ||

Model | GE272SM | GE272SP |

Needle | Compound needle | |

Working Width | 3454mm(136”) 5255mm(186”) | |

Gauge | E24,E26,E28 | |

Knitting Speed(MAX.) | 750rpm(136”) 750rpm(136”) 1300rpm(186”) 1300rpm(186”Chemical fibre) | |

Height of Terry | L1:4mm(MAX.) L4:6mm(MAX.) | 2mm or 3mm |

Number of Guide Bars | 4 guide bars(2 ground bars,2 terry bars) | 3 guide bars &1sinker bar |

Characteristics | The shog are under control of 6 tracks of pattern wheel.Fixed with a conversion device between terry loop and plain stitch. | 。 With an additional device,it can knit double terry fabric. |

Density Range | 6.18~70.4courses/cm | |

Power | (Main motor):5.5KW(136”); 9KW(186”) (Inching motor):0.75KW (Batching motor):1.5KW | |

Beams | φ535mmX535mm(φ21”X21”) orφ762mm X535mm(φ30”X21”) | |

Weight(Kg) | 8000 | |

- Q: What is the difference between yarn spinning and ring spinning?

- Ring spinning (combing) Process: clear flowers - carding - pre-parallel - articles and rolls - combing - the first road parallel - two parallel - roving - spinning - Winding

- Q: When the textile industry, as well as the history of the textile industry development?

- Chinese machine textile originated in five thousand years ago Neolithic spinning wheel and waist machine. Western Zhou Dynasty with the traditional performance of the simple mechanical reeling car, spinning, looms have emerged, the Han Dynasty widely used jacquard machine, oblique loom, after the Tang Chinese textile machinery is maturing, greatly promoted the development of the textile industry.

- Q: Textile equipment to protect the work is not a special type of work?

- Second, the former Ministry of Textile Industry "on the trial" textile industry chemical fiber toxic and hazardous operations early retirement range "notice [(88) spinning word No. 19) document, the viscose fiber 33 jobs (carbon disulfide manufacturing Workers, calcium sulphate liquid preparation workers, diggers, detergents, bleach, sulfonation, plate and frame filter workers, spinning workers, filament twist and drop silk workers, filament head workers, filament silk Workers, cellophane workers, iron chrome salt manufacturing workers, cotton linen preparation workers, bleach workers, carbon disulfide library workers, carbon disulfide safety workers, short fiber post-processing workers, carbon disulfide recycling workers, precision workers and spinneret finishing workers , Outside the precision workmanship, the strength of wire accessories replacement workers, waste silk cleaners, strong wire tube finishing workers, strong wire metering pump complete work, strong wire grading workers and loading and unloading silk workers, strong wire packer, strong wire early twist Block machine, strong silk weaving workers, strong silk with plastic workers, sulfonation machine and spinning machine to protect workers, acid station acid bath workers, acid station security workers) as toxic and hazardous special types of work and the four types of work (not Including mechanical operators Of the unloading of carpenters, log porter, turning carpentry, split woodworking) as a particularly heavy manual labor special work

- Q: What is the chenille mechanical principle?

- The machine's domestic model is in the digestion and absorption of foreign exhibitors on the basis of the prototype, after the transplant, redesigned and manufactured

- Q: Who invented Jenny spinning machine?

- In 1768, Hargreaves won the patent; by 1784, "Jenny machine" has increased to eight spindles. Four years later the United Kingdom has twenty thousand "Jenny machine".

- Q: What is the cashmere dyeing process?

- Consolidate all factors from the fiber to the end of the cost of spinning is not as the industry has reached a consensus that the dark color than dyeing light yarn cost is high, but light-colored, dark yarn cost is low, The highest cost of yarn

- Q: What is the task of preparing the process before spinning?

- Clear mixed in the raw cotton acrobatics and neps, impurity removal rate of 40% to 70%

- Q: What is the textile process?

- In addition to removing the neps, impurities and fiber defects in the fiber.

- Q: What are the mechanical characteristics of textile machinery?

- High efficiency, high efficiency, provincial maintenance; standardization, serialization, generalization; low energy consumption, low noise, low pollution, is the characteristics and direction of modern textile machinery.

- Q: What modern textile machinery?

- Textile machinery is usually classified according to the production process, including: spinning equipment, weaving equipment, printing and dyeing equipment, finishing equipment, chemical fiber spinning equipment, reeling equipment and non-woven equipment

Send your message to us

TERRY WARP KNITTING MACHINE GE272S SERIES

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords