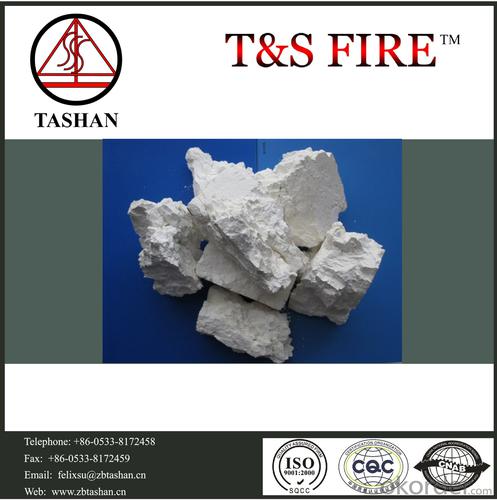

Raw Materials for Refractory:Flint Clay Aggregate

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 800T m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Calcined flint clay has been processed through a series of procedures, such as remove impurities, magnetic-selected to move iron and spraying drying etc. Water-washed kaolin has been used very effectively as functional filler in ceramic and so on.

Calcined flint clay is mainly used for manufacturing high-quality refractory products, refractory castable, sagger, kiln furniture, crucibles, ceramic fiber, precision casting sand, ceramics products, etc.

Features of calcined flint clay:

High refractoriness.

Physicochemical stability.

Volume density high.

Low porosity.

Low water absorption.

Fully calcined.

Low impurity content.

Pure white.

Specifications of calcined flint clay:

Size of particles: 0-1mm, 1-3mm, 3-5mm, 5-8mm, 8-15mm, 0-5mm, 0-50mm.

Size of sand: 8-16, 16-30, 30-60, 30-80, 60-80, 80-120 (mesh).

Size of powder: -200mesh, -270mesh, -325mesh.

Physical and chemical index of calcined flint clay:

| Item/Grade | YNS45 | YNS45 | YNS44 | YNS44 | YNS43 | YNS42 | YNS40 | YNS36 |

| A | B | A | B | |||||

| Al2O3 % | 46-48 | 45-48 | 44-48 | 44-48 | 43-48 | 42-46 | 40-46 | 36-42 |

| SiO2 % | 49-52 | 49-52 | 50-53 | 50-53 | 50-53 | 50-53 | 50-54 | 50-55 |

| Fe2O3 % (max) | 1.0 | 1.15 | 1.3 | 1.5 | 2.0 | 2.5 | 3.0 | 3.5 |

| TiO2 % (max) | 0.8 | 0.8 | 0.9 | 0.9 | 1.0 | 1.1 | 1.2 | 1.3 |

| K2O+Na2O % (max) | 0.3 | 0.3 | 0.4 | 0.4 | 0.4 | 0.5 | 0.5 | 0.6 |

| Ca0+Mg0 % (max) | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.6 | 0.7 | 0.8 |

| Bulk density g/cm3(min) | 2.58 | 2.55 | 2.52 | 2.50 | 2.45 | 2.40 | 2.37 | 2.30 |

| Refractoriness °C(min) | 1780 | 1770 | 1760 | 1750 | 1740 | 1720 | 1710 | 1700 |

| Impurities % (max) | 0.5 | 1.5 | 2.0 | 2.5 | 3.0 | 3.5 | 4.0 | |

- Q: Why can aluminium hydroxide not be used to make refractory material?

- Hope my answer is helpful to you. It decomposes and produces aluminium oxide and water after heating, chemical equation for the reaction is: 2Al(OH)3=△=Al2O3+3H2O. Aluminium hydroxide can't be directly used to make refractory material because aluminium hydroxide is not stable.

- Q: Who knows the setting requirements of roofing fire barrier zone?

- First, the the minimum of fire barrier width is greater than 30cm, and the thickness should be same to the thickness of the insulation materials. Fire barrier zone insulation board must do the whole area sticking construction with the base wall during the construction. Fire barrier zone insulation board is required to assistant binding by anchor bolt, anchor bolt must suppress the underlying mesh. Second, Fire barrier zone should be set at the upper position of door and window openings, the distance between the low edge of isolation belt and the upper edge of the window must be less than 50cm. The thermal resistance of fire barrier zone must be half than EIFS thermal resistance in the cold northern areas, while the thermal resistance of fire barrier zone must be three times than EIFS thermal resistance in the hot summer and cold winter area. Third, When the fire barrier zone is set on the edge of the window, fire barrier zone at the upper part of the window should do flanging when sticking, flanging glass fiber mesh must exceed 10CM than firebreak insulation board. Flanging network, underlying network and surface network can not be overlapped or butted at the top of the window. I hope you can be satisfied

- Q: Kinds of refractory mortar

- It needs no heating when hardened. There are two kinds of refractory mortar, the finished products and semi-finished products. Clinker is compounded in proportion according to the hardening temperature. (3) Chemical bonding refractory mortar is made from refractory aggregate and chemical binders (inorganic, high alumina refractory mortar). After this refractory mortar with thermal hardness is hardened, it has some contraction. Ther is a wide variety of refractories used on the constrcuction sites: // a, Advanced refractories (1770 ~ 2000 ℃) and AAA level refractories (2000 ℃ above). It can only be delivered in dry state. Air hardening refractory mortar is often compounded air hardening binders such as sodium silicate. It will harden below ceramic bonding temperature. According to different binding agents.

- Q: Refractory material, refractory brick

- 1, according to the degree of refractoriness:Ordinary refractory material: 1580 ~ 1770 DEG CAdvanced refractory material: 1770 ~ 2000 DEG CSuperfine refractory material: >2000 DEG C2, depending on the shape and size of the product:Standard type: 230mm * 113mm * 65mm;No more than 4 measurements, (size ratio) Max:Min<4:1;Profile: no more than 2 concave, (size ratio) Max:Min<6:1;Or an acute angle of 50~70 degrees;Specific type: (size ratio) Max:Min<8:1;Or not more than 4 or a sharp angle; 30 ~ 50 degrees;Special products: crucibles, vessels, tubes, etc.3, according to manufacturing methods, refractory materials can be divided into:Fired products, unfired products, unshaped refractories4. classification according to the chemical properties of materials:Acid refractory material, neutral refractory material, basic refractory material

- Q: What are the requirements of refractory temperature of refractory brick?

- Refractory bricks furnace pipe material is generally divided into two types, namely, shapeless refractory material and shaped refractory. Shapeless refractory material, also known as castable refractory, is hybrid powder material made up of many kinds of aggregate or aggregate and a kind of or many kinds of binders. It must cooperate and evenly stir with a kind or many kinds of liquids during use and has strong mobility. Shaped refractory material usually refers to refractory brick whose shape has standard rules. It can also be processed temporarily during cutting according to requirement. Refractory brick, called refractory brick for short, is refractory material made by firing refractory clay or other refractory raw materials. Faint yellow or brownish, it is mainly used in building smelting furnace. It can resist 1,580 ℃-1,770 ℃ high temperature.

- Q: Is there vermiculite in refractory?

- Vermiculite is usually used as lightweight material in refractory field, and its volume density is about 0.5.

- Q: What is the concept of lightweight refractory material?

- Lightweight refractory material has high porosity, mechanical strength and erosion resistance. Compared with normal refractory bricks, it is a kind of refractory material with large volume shrinkage in high temperature, low thermal conductivity and small bulk density. It is used as thermal insulation material in industrial furnace and other thermal equipments. It has poor wear resistancel.

- Q: which is better as household fireproof material ?

- If it is from the perspective of fire rating inorganic active insulation material for wall thermal, cement foam insulation board, glass beads of insulation movitrified?micro bead?thermal insulation?mortar, rock wool board, glass wool board, ect.. thermal insulation material are Class A fireproofing, polyphenyl board, extruded sheet, phenolic foam board, Polyurethane board, ect..belong to B1 level fireproofing, if it is used for external wall thermal insulation in decorative board, then rock wool board is more often used.

- Q: What is refractory cement?

- Refractory cement is also known as aluminate?cement. Aluminate?cement emplys bauxite and limestone as the raw materials, calcium?aluminate obtained by calcining as the main component, being made into clinker containing 50% of aluminium oxide and finally being made into hydraulic cementing material by grinding. Aluminate cement is often yellow or brown, sometimes gray. Aluminate cements' major mineral are monocalcium aluminate (CaO · Al2O3, abbreviated CA) and other aluminate as well as a small amount of dicalcium silicate (2CaO · SiO2), etc.

- Q: What are grades of refractory materials?

- Refractories have lots of varieties which all have different purposes.1 divided according to the level of refractoriness: ordinary refractory materials: 1580 ℃ to 1770 ℃, advanced refractories: 1770 ℃ to 2000 ℃ and super refractories: above 2000 ℃ 2, divided in accordance with shapes and sizes : Standard ones: 230mm × 113mm × 65mm, no more than four ruler.

Send your message to us

Raw Materials for Refractory:Flint Clay Aggregate

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 800T m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords