Flint Clay Raw Materials for Refractory

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 800T m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Calcined flint clay has been processed through a series of procedures, such as remove impurities, magnetic-selected to move iron and spraying drying etc. Water-washed kaolin has been used very effectively as functional filler in ceramic and so on.

Calcined flint clay is mainly used for manufacturing high-quality refractory products, refractory castable, sagger, kiln furniture, crucibles, ceramic fiber, precision casting sand, ceramics products, etc.

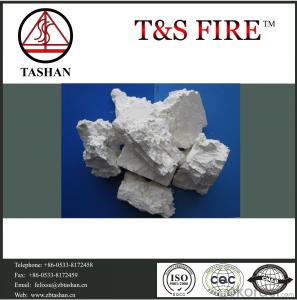

Features of calcined flint clay:

High refractoriness.

Physicochemical stability.

Volume density high.

Low porosity.

Low water absorption.

Fully calcined.

Low impurity content.

Pure white.

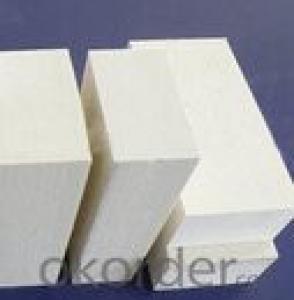

Specifications of calcined flint clay:

Size of particles: 0-1mm, 1-3mm, 3-5mm, 5-8mm, 8-15mm, 0-5mm, 0-50mm.

Size of sand: 8-16, 16-30, 30-60, 30-80, 60-80, 80-120 (mesh).

Size of powder: -200mesh, -270mesh, -325mesh.

Physical and chemical index of calcined flint clay:

| Item/Grade | YNS45 | YNS45 | YNS44 | YNS44 | YNS43 | YNS42 | YNS40 | YNS36 |

| A | B | A | B | |||||

| Al2O3 % | 46-48 | 45-48 | 44-48 | 44-48 | 43-48 | 42-46 | 40-46 | 36-42 |

| SiO2 % | 49-52 | 49-52 | 50-53 | 50-53 | 50-53 | 50-53 | 50-54 | 50-55 |

| Fe2O3 % (max) | 1.0 | 1.15 | 1.3 | 1.5 | 2.0 | 2.5 | 3.0 | 3.5 |

| TiO2 % (max) | 0.8 | 0.8 | 0.9 | 0.9 | 1.0 | 1.1 | 1.2 | 1.3 |

| K2O+Na2O % (max) | 0.3 | 0.3 | 0.4 | 0.4 | 0.4 | 0.5 | 0.5 | 0.6 |

| Ca0+Mg0 % (max) | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.6 | 0.7 | 0.8 |

| Bulk density g/cm3(min) | 2.58 | 2.55 | 2.52 | 2.50 | 2.45 | 2.40 | 2.37 | 2.30 |

| Refractoriness °C(min) | 1780 | 1770 | 1760 | 1750 | 1740 | 1720 | 1710 | 1700 |

| Impurities % (max) | 0.5 | 1.5 | 2.0 | 2.5 | 3.0 | 3.5 | 4.0 | |

- Q: what's the standard of fireproofing material?

- Class A1 is divided according to the combustion performance of GB8624-2006 building materials and products. Specific technical index requirements are: 1, the temperature rise ≤30 degrees;mass loss rate ≤50%; combustion duration time is 0; 2, main components, overall products, gross calorific value of external secondary components ≤2.0MJ/kg; any inner secondary component ≤1.4MJ/kg; (there are difference between homogeneous and non-homogeneous). Z802 building materials noninflammability testing furnace has to be used for testing technical indicators mentioned in test 1, using Z805 building materials combustion heat value to test technical indicators mentioned in test device 2.

- Q: Can anyone tell me what is A-leve fireproof material?

- What you say is probably palstic! B-level means the fireproof rating is at B1-level because palstic material doesn't belong to fireproof materials. It only is fire?retardant. When wholesaling all kinds of insulation materials and construction, it need tos look at the names. B1-level refers to the fire endurance rating of the fireproof material, which is determined according to the fire resistance of the material. In addition, different parts of the material have different fire endurance ratings! You can download a "Specifications of Fireproof Design for Buildings" for further information!

- Q: What are the fire endurance requirements of class A fire resistant door ?

- Fire endurance of class A fire resistant door is 1.5h. According to the latest fire door requirements, in FMA FMB FMC three forms, A, B and C represent categories, such as FMA on behalf of Class A fire doors (ie thermal insulation fireproof door). Fire endurances of class A,B and C fire doors are 0.5 1.0 1.5 2.0 3.0. Therefore, the fire resistance of fire door needs to be designed and the design paper will make it clear in general.

- Q: How many kinds of A-level fireproof and thermal insulation materials are there?

- Inorganic insulation materials basically can achieve the goal, such as glass wool, rock wool, and foam glass. The phenolic foam in the organic foam material is special. Phenolic foam is not only good at insulation, but also good at compounding with steel and other materials to achieve A-level performance, and the A-level insulation materials are: Rock(ore) wool, foam glass and inorganic thermal insulation mortar.

- Q: How much modulus is used as refractories material of sodium silicate.

- Storage and use are very convenient, especially for mechanized and the evenly refractory material and the sodium silicatemodulus is generally...2. transportation. The appearance of product is pure white. Instant powdered sodium silicate, also known as instant sodium metasilicate.4 to 3, in powder form, automation. in the range of 3, hydrated sodium silicate

- Q: How many types do refractory bricks have? Where the quality of refractory material is best? What is the model?

- Sinosteel Luoyang (Luoyang Refractory Material Plant in the past): High alumina(mainly blast furnace), Gongyi. There are also a series of high-tech materials (silicon carbide, carborundum, etc.) a major producer of high alumina; silicious: Resistant material for steel, glass furnace, cement kiln); magnesia. Divide from uses and divide from chemical texture; silicious(glass furnace): Xinmi, Hennan Province, Lengshui River, coke oven, etc.). As for the models, Yixing and Changxing in Jiangsu Province: Haicheng, Liaoning Province; silicious, I do not understand your intentions; magnesia (nonferrous, steel refining; magnesia: High alumina brick; Dashiqiao area! Please put it in detail.

- Q: What are the basic requirements of continuous casting for molten steel? What are the requirements for refractory materials?

- Refractories for continuous casting is an important part of the continuous casting machine, in addition to the characteristics of general refractory material, also for the purification of molten steel and improve the steel quality, stable molten steel temperature and composition, control and regulate the flow of the molten steel and other functions, so it is called functional refractories. The above is provided by the China Technology Department

- Q: What effect does aluminium powder play in refractory bricks?

- Aluminum powder is the main temperature resistant material ~ ~ ~ ~!

- Q: who knows how to classify the fire resistant levels of fireproofing material?

- Materials used in construction are called construction materials. The combustion performance of construction materials refers to all physic and chemical changes happened when burning or contacting fire, the properity is measured by combustibility of material surface and flame transmission, heating, smoke,charring, weightlessness, and the producing of toxicity resultant. Our national standard GB8624-97 classifies the combustion performance of construction materials into following several levels. Class A: Incombustible building material, class B1: Nonflammable building material, class B2: Combustible?building?materials, class B3: Inflammability construction materials, generally speaking: first fire resistant level construction is the mixed construction of reinforced concrete structure or brick wall and steel concrete structure; second fire resistant level construction is the steel structure roof truss, reinforced concrete column or mixed structure made by brick wall; third fire resistant level construction is the wood and brick made by wooden roof and brick wall; fourth fire resistant level one is the combustible?structure made by wooden roof, hard-comnustible component wall.

- Q: Classification of porosities in refractories and their effects on properties

- Effect of apparent porosity on properties:The porosity is high, the volume density is low, the structure become more loose, generally low strength, corrosion resistance worse (slag infiltration and erosion along the hole toward the inside), but to improve the thermal shock resistance (resistance to thermal shock and not damaged).

Send your message to us

Flint Clay Raw Materials for Refractory

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 800T m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords