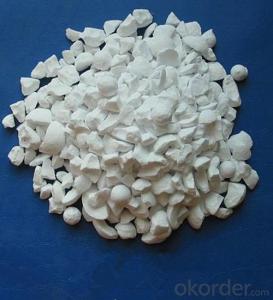

Raw Materials for Refractory:Tabular Alumina / Aggregates

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 Metric Ton/Metric Tons m.t.

- Supply Capability:

- 2000 Metric Ton/Metric Tons per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details of Tabular Alumina / Aggregates:

Place of Origin:China mainland

Material:Alumina Block

Shape:Block/Ball/Grain/Powder

Al2O3 Content(%):>99%

Color:White

Specifications of Tabular Alumina / Aggregates:

|

Shape |

Type |

Chemical Compositon |

Physical Characteristics | |||||||

|

Al2O3 |

Na2O |

SiO2 |

Fe2O3 |

Bulk Density |

Apparent Porosity |

Water Absorption |

Packed Bulk Density |

Cold Crushing Strength | ||

|

≥% |

≤% |

≤% |

≤% |

≥g/cm3 |

% |

% |

Kg/m3 |

N | ||

|

Ball |

RP-T162 |

99.7 |

0.20 |

0.02 |

0.02 |

3.65 |

1.5 |

0.4 |

2160-2000 |

2900-14700 |

|

RP-T164 |

99.5 |

0.30 |

0.04 |

0.03 |

3.55 |

3.5 |

0.8 |

2000-1860 |

2700-13500 | |

|

RP-T60 |

99.3 |

0.40 |

0.09 |

0.02 |

3.50 |

5 |

1.5 |

|||

|

RP-T61 |

99.1 |

0.40 |

0.13 |

0.03 |

3.45 |

6 |

2.0 | |||

|

Granule |

RP-T60G |

99.3 |

0.40 |

0.10 |

0.02 |

3.50 |

5 |

1.5 |

(mm) 5-10 3-6 3-1 1-0 0.5-1 0.2-0.6 | |

|

RP-T61G |

99.1 |

0.40 |

0.13 |

0.03 |

3.45 |

6 |

2.0 | |||

|

Micro Powder |

RP-T60P45 |

99.2 |

0.40 |

0.09 |

0.02 |

3.50 |

5 |

1.5 |

(μm) -45μm (-325mesh) -20μm (-635mesh) | |

|

RP-T60P20 |

99.1 |

0.40 |

0.15 |

0.04 |

3.50 |

5 |

1.5 | |||

|

RP-T61P45 |

99.1 |

0.40 |

0.12 |

0.03 |

3.45 |

5 |

1.5 | |||

|

RP-Y61P20 |

99.0 |

0.40 |

0.15 |

0.04 |

3.45 |

5 |

1.5 | |||

Packaging & Delivery of / Aggregates:

Packaging details:1mt big bag or according to customers’ requirements

Delivery:7-15 work days after the order is confirmed

Application:

It is used in a variety of industries such as steel, foundry, petrochemical, ceramic and incineration.

Other common applications include its use in electrical insulators, kiln furniture and as a catalyst support.

Advantages:

High Purity & Good Quality.

Good Hardness & High Heat-resistance.

Competitive Price & Reputable Supplier.

Timely delivery & service

Good company reputation

- Q: What are the models of refractory cables?

- There are bout four types. 1.NA-YJV / NB-YJV Crosslinked polyethylene insulated PVC sheath A (B) class fire-resistant power cable 2.NA-YJV22 / NB-YJV22 Crosslinked polyethylene insulated steel belt braiding PVC sheath A (B) class fire-resistant power cable 3.WDNA-YJY / WDNB-YJY Crosslinked polyethylene insulated polyolefin sheath A (B) class low smoke no halogen fire retardant power cable 4.WDNA-YJY23 / WDNB-YJY23 Crosslinked polyethylene insulated steel belt braiding polyolefin sheath A (B) class low smoke no halogen fire retardant power cable

- Q: How to calculate the thickness of choosing refractory? Such as steel ladle should choose what kind of refractory and using what thicknes?

- I feel the concrete thickness should depend on the experience and the actual situation. As for the specific method, I also can't say too accurately. If it's ladle, it generally chooses alumina magnesia castable.

- Q: How many types of special refractories are there?

- Metal ceramics, high temperature coatings, high temperature fiber and other reinforced materials

- Q: Which refractory quality inspection authority is good?

- Research Institue of Refractory Materials in Luoyang, Henan Some of our samples are made there.

- Q: The difference between refractory and thermal insulation material

- Refractory refers to inorganic non-metallic material, whose refractoriness is not less than 1,580℃, but refractory is not necessarily insulated material. Inorganic thermal insulated material also belongs to refractory as long as its refractoriness is higher than 1,580℃.

- Q: What refractories are used in various parts of the blast furnace.

- Blast furnace from top to bottom has the throat, hearth staves, waist, bosh, hearth and furnace bottom. the specific structure is as follows: The throat is the first to be affected by the impact and abrasion, generally use high-density alumina bricks. the upper and central portion of temperature furnace is only 400 ~ 800 ℃, the area with high alumina bricks and silicate bricks. The lower part of furnace is subject to erosion and dust erosion alkali metal vapor due to high temperatures, it is required in such case to use high quality clay brick,high alumina brick,carborundum brick,corundum brick that is slag resistance and alkali?resistance, temperature resustant and wearproof. Furnace bosh temperature reached 1400 ~ 1600 ℃, serverly eroded by slag,vapor, flush. so we use carborundum brick and reaction-bonded silicon?carbide?brick. Bosh temperature reaching1600 ~ 1650 ℃, using alumina brick, corundum brick or silicon carbide brick. the temperature of Hearth near the upper portion of the outlet zone at 1700 ~ 2000 ℃, use of silicate bricks and corundum castable graphite filler, silicon carbide bricks. In 1450 Silly twitch bottom temperature sealing die of hunger slander bet phoenix astringent preserved Grade ~ 1500 ℃, use of graphite bricks and microporous carbon bricks, now use more corundum brick, corundum mullite brick and synthetic mullite brick. x26lt;P class x3d "share-btn"x26gt;

- Q: I would like to ask a friend that how much is the fire endurance of level A fireproofing glass?

- the fire endurance of fire window is: class A window is not less than 1.2 hours, class B window is not less than 0.9 hours, Class C window is not less than 0.6 hour. technical requirements: 1, materials and accessories (1) the window frame is made by a certain strength of steel frame or wooden frame which is sufficient to safeguard the integrity and stability. (2) steel frame and mound layer can select galvanized?steel?sheet or stainless steel plate. Its selection standards should be in line with the provisions of Article 5.1. in GB12955 "Steel Fireproof Door General Technical Condition" (3) the selection standards of wood frame and mound layer should be consistent with the provisions of Article 5.1.1. in GB14101 "General Technical Conditions of Wooden Fireproof Door" (4 ) the inner filling material of steel and wood frame should be non-combustible material. (5) fireproofing glass can choose the qualified products in fire resistance test and not affecting the fire windows. light transmittance of glass is not less than 75% of identical layers of ordinary plate glass. ( 6) a sealing material between the frame and the fireproofing glass should use the nonflammable material, it can play the role of fireproofing and smoke insulation in the fire disaster. I hope I can help you

- Q: What are the materials of class A fire resistant window?

- The filling materials of steel, wood frame should be non-combustible materials. Fireproof glass can use qualified products that do not affect the fire window fire resistance performance, whose light transmittance should be no less than 75% that of the commom sheet glass with the same layers. Sealing materials between the frame and fireproof glass should be nonflammable materials. Hardware fittings should be fixed supporting products that pass the test.

- Q: what's the requirements of refractory for forge furnace?

- High temperature resistance, good slag resistance.

- Q: Is it necessary for the frame of glass fireproof door to be crammed with fire-proof material?

- Close the door , and check if the gap is normal, whether the hole and the door leaf are in the same plane, and whether the door leaf has tendency to fall down. Fire resistance steel door——means that use a cold rolled steel sheet as door frame, door plank and framework, and stuff a door leaf with incombustible material.

1. Manufacturer Overview

| Location | Tianjin,China |

| Year Established | 2006 |

| Annual Output Value | Below US$1 Million |

| Main Markets | Mid East;Western Europe;Japan;North America |

| Company Certifications | The Authentication certificate of Quality Management system |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 61% - 70% |

| No.of Employees in Trade Department | 50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 300,00 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | Design Service Offered |

| Product Price Range | Average |

Send your message to us

Raw Materials for Refractory:Tabular Alumina / Aggregates

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 Metric Ton/Metric Tons m.t.

- Supply Capability:

- 2000 Metric Ton/Metric Tons per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords