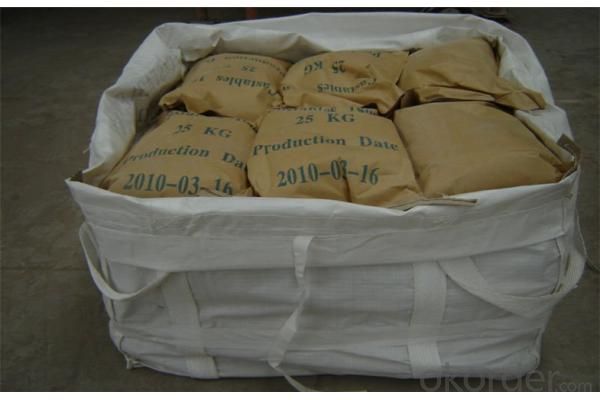

Raw Materials for Refractory:High Refractoriness Aluminum Mortar Cement for Metallurgy Steel Casting

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High aluminum cement can be used in the manufacture of prepared monolithic refractories, preparation of plaster alumina cement, self-stressing cement, cement with other special purposes, and maintenance, resistance to sulfate erosion and winter construction of engineering with other special needs.1. Cement CA-50 with Excellent high temperature.

Technical index

Item | CA-50 | CA-70 | CA-90 | |

Al2O3 | % | ≥50, | ≥70 | ≥90 |

SiO2 | ≤8.0 | ≤8.0 | ≤8.0 | |

Fe2O3 | ≤2.5 | ≤2.5 | ≤2.5 | |

S | ≤0.1+ | - | - | |

CaO | 30 | 25 | 9 | |

Refractoriness | ℃ | 1550 | 1650 | 1750 |

Size | Mu | 180 | 180 | 180 |

Physical and Chemical Properties

Product Name | Low cement and high alumina castable | |

Product Code | LH-16B | |

Density (kg/m3) | ≥2.5 | |

Chemical Component (%) | AL2O3 | ≥65 |

SiO2 | 20 | |

Cold Crushing Strength(MPa) | 110°C*24h | ≥80 |

1100°C*3h | ≥80 | |

Modulus of Rupture(MPa) | 110°C*24h | ≥8 |

1400°C*3h | ≥10 | |

Linear Change Rate(%) | 1100°C*3h | -0.1—--0.3 |

Water Consumption of Construction (%) | 6~7 | |

Maximum Service Temperature(°C) | 1400 | |

Application Part | The front end of cooler, precalciner, heat-resisting parts and lining of other industrial kiln.

| |

- Q: How can refractory material of the electric furnace be used for longer.

- Key: 1, consider the furnace size; As furnace volume differs, pressure of liquid iron (steel) on the crucible wall lining will not the same; 2, consider melting steel type: If different steels are melt, the erosion of steel liquid on the lining refractory is not the same; 3, give full consideration to the lining of the grain size distribution of the refractory material, otherwise, it will cause of refractory matrix size segregation. 4, regardless of the kind of refractory materials, take full consideration into the mineral phrase of refractory material, high temperature and other equal factors. 2011 - 01 - 05 Guangyi mineral

- Q: Who can tell me what is neutral refractory?

- It is a material that can resist acidic and basic slag, flux and chemical erosion form other refractories at high temperatures. The main components include carbon, silicon carbide, aluminum oxide, chromium oxide and other trivalent oxides, such as carbon refractories and chrome refractories, etc. Strictly speaking, neutral refractories refer only to the carbonaceous refractories, including carbon brick and graphite silicon carbide products, etc. Sometimes, high alumina refractories with high Al2O3 content also belong to this material, such as some materials that are acidic but tend to be basic refractories, like sillimanite, mullite bricks and corundum bricks. Recently developed aluminum carbon bricks, zirconium carbon bricks alumina - silicon carbide - carbon bricks, silicon nitride bonded silicon carbide brick and so on are also neutral refractories. This material can be used in the bottom of blast furnace, the lining of hearth and bosh, and the lining of aluminum electrolytic cell, calcium carbide furnace, ferroalloy furnace, molten steel ladle, plating tank, reaction tank, and autoclave and so on.

- Q: Who knows the fire rating of fire?partition with steel stud?

- Cement board wall of steel stud: it is used for walls with ceramic in kitchens, restroom, disinfect room, etc. If single-sided tile is made, cement pressure plate can be used on one side. Gypsum board is used on the other side. Fire?rating is A1. CaSo4.2H2O is molecular structural formula of gypsum which contains 20% water, crystal water and free water. When 10% water slowly evaporates on the flame surface, there is still 10% crystal water. Itself is grade A fire retardant material. 1 hour. It is in line with the fireproof test standard of national building materials. It can reach up to 4 hours at most.

- Q: What's the fire endurance of hollow brick?

- This question is really very simple. It is better no to exceed 1050℃, or it will be easily burnt. I think 980℃ is ok actually. Around 950℃, no more than 1100℃, or brick will be burnt and melted easily.

- Q: What's the definition of fire endurance of the fire-resistant coating for steel structure?

- Fire endurance (h): Under the condition of standard fire resistance test, the time when the building components, accessories, or structure is subjected to fire to the time when they loose stability, integrality or thermal insulation is called fire endurance which is showed in time. Steel is the kind of building material that is nonflammable with many properties of seismic resistance and bending resistance. In practical applications, steel can improve the load capacity of buildings in a relative way, meet the needs of buildings design, beauty and mould, and it can also avoid the defects of poor flexibility and tensile strength of buliding materials like concrete. Therefore, steel is quite popular in the construction industry, and it is widely used in single-story or multi-storey skyscrapers, plants, warehouses, waiting rooms and airport terminals, etc. However, as a kind of building material, it has some unavoidable defects in fire prevention. That is its mechanical properties like yield point, tensil strength and elasticity modulus will decrease dramatically with the rise of the temperature.

- Q: Selection of refractory materials?

- Acid refractory with silicon oxide as the main component, are commonly used in brick and clay brick. Silica is silica containing more than 93% silica products, raw materials used in silica, silica and other waste, the acid resistance of slag erosion ability, high load softening temperature, volume shrinkage after repeated burning, or even a slight expansion; but it is vulnerable to the erosion of basic slag, low thermal shock resistance. The brick is mainly used for thermal equipment of glass furnace, coke oven, acid furnace etc.. Clay brick with refractory clay as the main raw material, containing 30% to 46% of alumina, weak acid refractory material, heat shock resistance, resistance to acid slag, widely used.

- Q: What are the fire resistances of grc partition panels?

- waterproofing: It has good water resistance; 2. fireproofing: fire resistance of partition panel≥3.5h, it has an excellent fireproof performance and can be applied to fire-proof bulkhead; 3.soundproofing: According to the different thickness of walls and surface treatments, perlite light partition panels insulation can be 40-50 decibels, to ensure that products can be used for office, commercial, entertainment and residential buildings; 4, light weight:

- Q: What are the types of steel refractory materials

- The major category is classified as permanent layer, working lining. Specific varieties: Air permeable brick (corundum). steel ladle brick (magnesia or corundum), permanent layer castable (high alumina), reinforcing material for ladle bottom, repair material for the edge of tank and so on.

- Q: How many external wall thermal insulation fireproof material are there

- Class A exterior wall insulation: Rock wool, glass wool, silicate, aluminum silicate, calcium silicate, phenolic foam, foam glass

- Q: Where is the development of refractory industry?

- Continuous casting system varieties used in refractory materials include: (1) ladle refractories -- ladle lining, permanent lining, ventilation components; (2) tundish refractories -- linings and coatings, insulation board, cover; (3) functional refractories -- non oxidation casting with long nozzle, immersion nozzle, stopper, sliding gate; (4) purifying molten steel with ceramic purifier, slag dam, alkaline coating and horizontal continuous casting for separating ring gate, etc..

Send your message to us

Raw Materials for Refractory:High Refractoriness Aluminum Mortar Cement for Metallurgy Steel Casting

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords