Aluminum Foil Facing Flexible Duct 40mm Width with PE

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

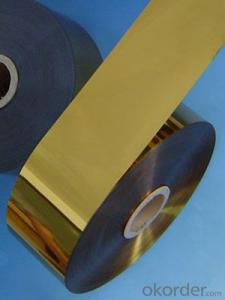

Introduction of Aluminum Foil Facing

Aluminum Foil Facing is a kind of film, which is made of by the aluminum foil, fiberglass scrim and Kraft paper. Someone is made of by aluminum and PE woven fabric cloth.

Application of Aluminum Foil Facing

Our aluminum foil facing are mainly used as facing for glass wool insulation, rockwool, mineral wool etc. Also aluminum foil facing is used under roof decking, under attic rafters, over existing attic thermal insulation, in floors, walls and crawl spaces, and in industrial and commercial buildings to block radiant heat coming into house through the roof during the summer and retain indoor heat generated during in winter

Advantage of Aluminum Foil Facing

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• High reflective insulation

• Heat resistant, water proof, stable at high temperature;

• environmentally friendly, no smell and not-toxic;

• Smooth and clear surface;

Packing of Aluminum Foil Facing

1. Waterproof paper then PVC shrinking Film

2. Kraft paper only

3. Woven cloth

4. Kraft paper or Water Proof Film then Metal/wooden pallet

5. (Also as your request. )

Product Data Sheet

PROPERTIES | UNIT | VALUE | TEST METHOD |

Basic weight | gsm | 33.5 | ASTM D646 |

Thickness | mic | 23.2 | ASTM D646 |

Tensile strength: M. D. X. D. | N/15mm | 13.5 13.5 | ASTM D882 |

Delaminating Values | N/15mm | 1.5 | ASTM D904 |

Reflectivity of foil surface | % | 95 | ---------- |

Temp. Resistance | -40°C 130°C | No Delamination No Delamination | ASTM C1263 |

Water vapor permanence | ng/N.s | 1.15 | ASTM E-96 |

Product Picture

FAQ

1. What is the product keeping conditions?

The Aluminum Foil Facing should be stored at room temperature and kept from wet and heat source.

2. What is the guarantee years of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. What is the delivery time of the order?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: What are the recommended cleaning products for aluminum foil facing after use?

- <p>For cleaning aluminum foil facing after use, it's best to use gentle, non-abrasive cleaning products. Mild dish soap and warm water are usually sufficient for most cleaning needs. Avoid using harsh chemicals or abrasive scrubbers, as they can damage the aluminum surface. If there are stubborn stains, a mixture of baking soda and water can be used as a gentle abrasive. Always rinse thoroughly and dry the surface to prevent any residue or potential damage.</p>

- Q: Is it possible to use aluminum foil with a facing layer to wrap sandwiches?

- <p>Yes, aluminum foil facing can be used to wrap sandwiches. It provides a barrier to keep the sandwich fresh and protected. However, it's important to ensure that the facing layer is food-safe and doesn't contain any harmful substances that could leach into the food. Always check the packaging to confirm that the aluminum foil is suitable for food contact.</p>

- Q: Is inhaling aluminum oxide particles from aluminum foil dangerous to health?

- <p>Breathing in aluminum oxide particles is generally not harmful in small amounts, as the human body can handle trace amounts of aluminum. However, prolonged exposure to high concentrations of aluminum oxide dust can cause respiratory issues and may have potential health risks. It is always advisable to handle aluminum foil and other materials that could generate dust in a well-ventilated area to minimize the risk of inhalation.</p>

- Q: This question asks about potential health hazards linked to consuming food that has been wrapped in aluminum foil.

- <p>There are minimal health risks associated with eating food wrapped in aluminum foil. Aluminum foil is generally safe for cooking and food storage. However, it's important to avoid wrapping acidic or high-sodium foods in aluminum foil, as these can cause the foil to corrode and potentially release small amounts of aluminum. Long-term consumption of aluminum in large quantities has been linked to rare health issues, such as Alzheimer's disease, though this link is not definitively proven. To be safe, use aluminum foil sparingly and avoid wrapping foods that are highly acidic or salty.</p>

- Q: Explain how to best utilize aluminum foil facing in the preparation of a sandwich.

- <p>The best ways to use aluminum foil facing in a sandwich include: 1) Wrapping the sandwich to keep it fresh and prevent it from drying out, especially when storing for later. 2) Using it as a makeshift 'grill' by placing the sandwich between two sheets of foil and toasting it in a panini press or on a stovetop for a crispy exterior. 3) Creating a foil pouch by sealing the sandwich in foil, which can be used for cooking sandwiches in an oven or on a campfire, keeping the ingredients moist and tender. 4) Using foil to press down on the sandwich while grilling or toasting, ensuring even heat distribution and a uniform texture. Always ensure the foil is food-safe and does not come into direct contact with the sandwich's fillings to avoid any potential contamination.</p>

- Q: Is it safe and hygienic to repurpose a piece of aluminum foil that was previously used for wrapping food?

- <p>It is generally not recommended to reuse aluminum foil that has been in contact with food. Used foil can have residues of food, grease, and bacteria, which can contaminate new food items. Additionally, the foil can tear or become thin in areas, reducing its effectiveness and potentially allowing food to stick to previously used, contaminated areas. For椋熷搧瀹夊叏 and hygiene, it's best to use a fresh piece of aluminum foil each time.</p>

- Q: Is it safe to use aluminum foil with a facing layer for storing salad dressings or oils?

- <p>Yes, it is generally safe to use aluminum foil facing for storing salad dressing or oil. Aluminum foil facing is designed to provide a barrier against air and moisture, which helps to keep the contents fresh. However, it's important to ensure that the foil is food-grade and that it does not have any sharp edges that could puncture the container. Additionally, it's best to store these items in a cool, dry place away from direct sunlight to maintain their quality and prevent spoilage.</p>

- Q: What precautions can be taken to prevent burns while using aluminum foil in cooking or baking?

- <p>To avoid getting burned when using aluminum foil for cooking or baking, follow these safety tips: Always handle the foil with utensils or wear heat-resistant gloves. Avoid touching the foil directly after cooking or baking, as it can retain heat. Use heavy-duty aluminum foil to prevent punctures and tears that can cause burns. Keep aluminum foil away from open flames or high heat sources to prevent it from catching fire. Always use caution when removing aluminum foil from an oven or stovetop, and let it cool slightly before handling.</p>

- Q: Is it possible to replace plastic wrap with aluminum foil for food storage in containers?

- <p>Yes, aluminum foil can be used as a substitute for plastic wrap in food storage containers. It effectively seals in freshness and prevents air exposure, which is similar to the function of plastic wrap. However, aluminum foil is not airtight and may not be as effective in preventing the escape of odors or the entry of bacteria as plastic wrap. Additionally, it is not microwave-safe and can be less convenient for re-sealing. It's also important to ensure that the foil does not come into direct contact with acidic or alkaline foods, as this can lead to a reaction and potential contamination.</p>

- Q: Is it safe to use aluminum foil facing to wrap vegetables or fruits for roasting or grilling?

- <p>Yes, you can use aluminum foil facing to wrap vegetables or fruits before roasting or grilling. Aluminum foil is a common and safe method for cooking food as it retains moisture and heat, allowing for even cooking. However, ensure that the foil does not come into direct contact with the heat source for extended periods to avoid any potential risk of aluminum leaching into the food. It's also important to use heavy-duty aluminum foil for cooking to prevent tearing or puncturing during the cooking process.</p>

Send your message to us

Aluminum Foil Facing Flexible Duct 40mm Width with PE

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords