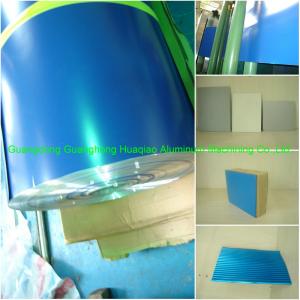

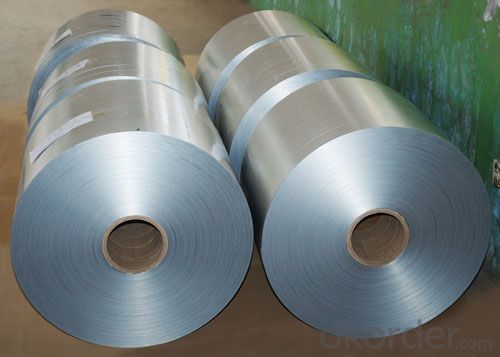

Flat Rolled Aluminum Coil Ohio - Alloy 6061 T6 China Distributor 2mm 3mm 4mm Aluminum

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Alloy 6061 T6 China Distributor 2mm 3mm 4mm Aluminum

Packaging & Delivery

| Packaging Details: | Standard seaworthy packages in bundles or as per requirement. Container size: The inner size of container is below: 20ft GP: 5.8m(length) x 2.13m(width) x 2.18m(high) about 24-26CBM 4 0ft GP: 11.8m(length) x 2.13m(width) x 2.18m(high) about 54CBM 40ft HG: 11.8m(length) x 2.13m(width) x 2.72m(high) about 68CBM(stainless steel seamless pipe) |

| Delivery Detail: | Within 5-15 days after deposit(price of aluminum coil) |

Our Services

1. Provide products with high quality and reasonable price

2. The first time back to you

3. Perfect after-sale service

4. Small order is acceptable

5. OEM is acceptable

6. 12Months quality guarantee

7. Any third party testing is acceptable

Product Description

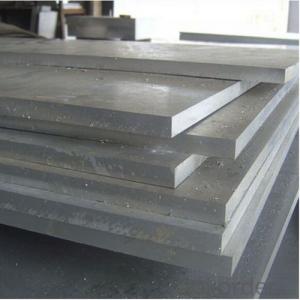

| Product Name | Prices of aluminum coil |

| Standard | JIS, AISI, ASTM, GB, DIN |

| Alloy | Yes |

| Width | 720-1250mm or as the customers' requirements |

| Length | 10000-12000mm mm or as the customers' requirements |

| Thickness | 0.12-1.5mm |

| Surface | Black painted,PE coated,GL,color coated,etc |

| Item | steel plate,steel sheet,alloy plate,alloy sheet |

| Application | construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields ,etc. |

| Packing | Export standard or as customers' requirement |

| Delivery time | Within 7 working days, according to customers' quantities |

| Payment | L/C or T/T or as customers' requirement |

| MOQ | 1 Ton |

| Quality | High Quality. We can Provide SGS inspection if you need . |

| Productivity | 60000 Tons/Month |

| Attention | We will supply you good quality and bottom price and first-class service in china and hope to be your golden supplier |

- Q: Can we provide raw materials, aluminium coils and aluminum panels for several integrated ceilings?

- You go to my space, add my QQ bar, I do aluminum, aluminum coil, aluminum wafer, and I also want to know about the requirements of integrated ceiling ~ ha ha!

- Q: Which is better composite or aluminum, and what are some main differences between the two?

- composites are so much better. the ball will travel way farther and your hands wont sting if you hit the ball on the handle. they are much better trust me

- Q: Do you have an aluminum coil first? Is there an aluminum plate?

- Yes, all aluminium sheets are made of aluminium rolls after slitting. The general process of aluminum plate production is: aluminium ingot - aluminum water - casting roll - aluminum roll ---- aluminum plate [Ji'nan excellent aluminum industry]. Welcome to visit.

- Q: What are the safety precautions required when handling aluminum coils?

- When handling aluminum coils, there are several safety precautions that should be followed to ensure the safety of individuals and minimize the risk of accidents. 1. Personal Protective Equipment (PPE): It is essential to wear appropriate PPE, including safety glasses or goggles, gloves, and steel-toed boots. This equipment provides protection against potential injuries caused by sharp edges or flying metal particles. 2. Proper Lifting Techniques: Aluminum coils can be heavy, so it is important to use proper lifting techniques to avoid strains or back injuries. Always lift with your legs, not your back, and use lifting aids or equipment when necessary. 3. Secure Storage and Handling: Store aluminum coils in a well-ventilated area that is free from excessive heat or moisture. It is important to stack them properly and securely to prevent them from falling or rolling, causing injury to nearby individuals. 4. Fire Prevention: Aluminum is highly flammable when in the form of a fine powder or shavings. Therefore, it is crucial to keep the working area clean and free from combustible materials. Additionally, smoking or open flames should be strictly prohibited in the vicinity. 5. Avoid Sharp Edges: Aluminum coils can have sharp edges that can cause cuts or lacerations. Always handle them with care and use appropriate tools or equipment when cutting or shaping the coils to minimize the risk of injury. 6. Training and Education: Proper training and education on handling aluminum coils should be provided to all individuals involved in the process. This includes understanding the material properties, safe handling techniques, and emergency procedures in case of accidents or spills. 7. Chemical Hazards: Aluminum coils may be coated or treated with chemicals. It is important to be aware of any potential hazards associated with these coatings and follow proper safety procedures when handling or working with them. By following these safety precautions, individuals can reduce the risk of accidents, injuries, and potential hazards when handling aluminum coils. It is crucial to prioritize safety and ensure that all employees are trained and equipped with the necessary knowledge and protective gear.

- Q: What are the different coil leveling options available for aluminum coils?

- Aluminum coils can be leveled using various methods, depending on the specific needs of the application. These options include roller leveling, stretch leveling, tension leveling, and precision leveling. Roller leveling is a commonly used technique that involves passing the coil through a series of rollers. These rollers apply pressure to gradually reduce the thickness of the material and correct any imperfections. This method is efficient and can accommodate different coil sizes and thicknesses. Stretch leveling, on the other hand, involves controlled stretching of the aluminum coil. Powered rollers elongate the material, removing residual stress and improving flatness. This method is particularly effective for thicker and wider coils. Tension leveling utilizes tension to eliminate waviness or unevenness in the coil. The material is passed through bridle rolls that apply tension, resulting in a flattened coil. This technique is commonly used for thinner gauges of aluminum and allows for high-speed processing. For high-precision applications, precision leveling is recommended. This specialized process combines roller leveling, stretching, and tensioning techniques to achieve extremely flat and uniform coils. Industries such as aerospace, automotive, and electronics often rely on precision leveling. Overall, the choice of leveling method for aluminum coils depends on factors like desired flatness, thickness, width, and application requirements. Each technique has its own advantages and limitations, so it is crucial to select the most suitable option to ensure the production of high-quality end products.

- Q: How much does it cost to extract aluminium from its raw ore? Also how much does extracted aluminium sell for? I cannot find this anywhere on the internet. I would really appreciate some help.

- These are the points to think about: The high cost of the process because of the huge amounts of electricity it uses. This is so high because to produce 1 mole of aluminium which only weighs 27 g you need 3 moles of electrons. You are having to add a lot of electrons (because of the high charge on the ion) to produce a small mass of aluminium (because of its low relative atomic mass). Energy and material costs in constantly replacing the anodes. Energy and material costs in producing the cryolite, some of which gets lost during the electrolysis. The key cost of the electrolysis and the cost of electricity. This will depend which country you are in, which you don't tell us. If freely available hydroelectric power is available, this makes a huge difference. IF you are in the US, the costs of extracting aluminium or any metal is 70% to 95% of the current market value. Aluminium is selling at about $1500/tonne, then the cost of extracting it can be around $1200/tonne.

- Q: What is the elongation of aluminum coils?

- The elongation of aluminum coils refers to the amount of stretching or deformation that can occur in the material before it breaks or becomes permanently damaged. It is a measure of the ductility or ability of aluminum to withstand tensile forces without fracturing.

- Q: show step by step

- First write out the formula reaction: 4Al + 3O2 --- 2Al2O3 Next, find the number of moles of oxygen gas needed to oxidize 3.42 g of aluminium completely. From the cchemical equation above, 3 mol of oxygen is used to oxidize completely 4 mol of aluminium. Calculate the no. of moles of aluminium used: no. of moles of aluminium used = 3.42 g / molar mass of Al = 3.42 g / 26.98 g mol^-1 = 0.127 mol Use the mole ratio concept to find the no. of moles of oxygen required: no. of moles of oxygen required : no. of moles of aluminium used = 3 : 4 no. of moles of oxygen required / 0.127 = 3 / 4 no. of moles of oxygen required = (3 / 4)(0.127) = 0.095 mol Next, use the gas equation PV = nRT [P: Pressure of gas in Pa; V: Volume of gas in m^3; n: no. of moles; R, gas constant, 8.314 J mol^-1 K^-1; T, Temperature of gas in K] -Convert 0.975 atm to Pa: 0.975 atm = (0.975 x 101325) Pa = 98791.875 Pa -Convert 25 oC to K: 25 oC = (25 + 273) K = 298 K -Substitute into the equation PV = nRT and solve it: (98791.875)(V) = (0.095)(8.31)(298) (98791.875)(V) = 235.2561 V = 235.2561 / 98791.875 = 0.002381 m^3 = (0.002381 x 10^3) L = 2.381 L

- Q: What are the different surface treatments applied to aluminum coils?

- There are several different surface treatments that can be applied to aluminum coils to enhance their appearance, protect against corrosion, and improve their overall performance. Some of the most common surface treatments for aluminum coils include: 1. Anodizing: Anodizing is an electrochemical process that forms a protective oxide layer on the surface of the aluminum. This treatment enhances the corrosion resistance of the coils and provides a decorative finish. Anodized aluminum coils are available in a wide range of colors and finishes. 2. Painting: Painting is a surface treatment that involves applying a coating of paint to the aluminum coils. This treatment provides a decorative finish and can also enhance the corrosion resistance of the coils. Painted aluminum coils are commonly used in architectural applications where aesthetics are important. 3. Laminating: Laminating is a process that involves applying a thin layer of protective film to the surface of the aluminum coils. This treatment provides a protective barrier against scratches, abrasion, and UV radiation. Laminated aluminum coils are often used in applications where durability and weather resistance are important. 4. Polishing: Polishing is a mechanical process that involves buffing the surface of the aluminum coils to create a smooth and shiny finish. This treatment enhances the appearance of the coils and can also improve their corrosion resistance. Polished aluminum coils are commonly used in decorative applications where a high-end look is desired. 5. Brushing: Brushing is a mechanical process that involves creating a pattern of fine parallel lines on the surface of the aluminum coils. This treatment gives the coils a brushed or satin finish and can also help to hide imperfections and scratches. Brushed aluminum coils are often used in applications where a modern and sleek appearance is desired. Overall, the choice of surface treatment for aluminum coils depends on the specific application requirements and desired aesthetic. Each treatment offers unique benefits in terms of appearance, corrosion resistance, and durability, allowing manufacturers and designers to select the most suitable option for their needs.

- Q: How are aluminum coils tested for quality control?

- Aluminum coils undergo several tests during quality control to ensure their reliability and performance. One of the primary tests is the dimensional inspection, where the physical dimensions of the coils are measured and compared against the specifications provided by the manufacturer. This helps to identify any discrepancies in length, width, thickness, or diameter. Another crucial test is the visual inspection, where the coils are thoroughly examined for any surface defects such as scratches, dents, or discoloration. This visual examination is essential to ensure that the coils meet the required aesthetic standards. To evaluate the mechanical properties, various mechanical tests are conducted. Tensile strength tests are performed to measure the resistance of the aluminum coils to breaking under tension. This test helps in determining the durability and strength of the coils. Additionally, hardness tests are carried out to assess the coil's resistance to indentation or deformation. The hardness values are compared against the predetermined standards to verify if the coils meet the necessary criteria. Further tests include corrosion resistance testing, where the coils are exposed to harsh environments or corrosive substances to assess their ability to withstand corrosion over time. This test is crucial as aluminum is often used in applications where it may come into contact with corrosive elements. Electrical conductivity tests are conducted to ensure the proper functioning of the coils in electrical applications. The conductivity is measured and compared with the required specifications to guarantee that the coils possess the desired electrical characteristics. In addition to these tests, other factors like chemical composition analysis, surface roughness evaluation, and coating adhesion tests may also be performed depending on the specific requirements of the aluminum coils. Overall, through these comprehensive quality control tests, manufacturers can ensure that aluminum coils meet the necessary standards, guaranteeing their quality, performance, and reliability in various applications.

Send your message to us

Flat Rolled Aluminum Coil Ohio - Alloy 6061 T6 China Distributor 2mm 3mm 4mm Aluminum

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords