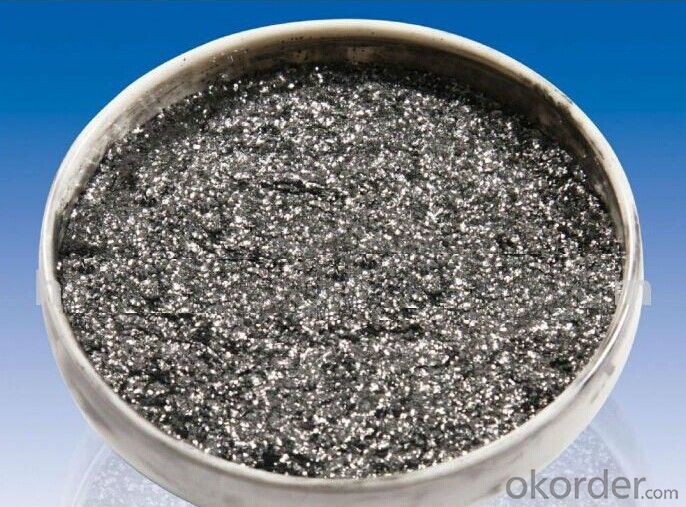

Raw Materials for Refractory:Flake Graphite with Good Quality and Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t

- Supply Capability:

- 5000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Flake Graphite With Good Quality And Price

Features

Governmental Company

Good Quality& High Heat-resistance

Competitive Price & Timely delivery

Product Description

1.Types:High-purity graphite,high carbon grahite.

2. Specifications:The particle size ranges from (325mesh-35mesh),

and the carbon content ranges from85 to 99.9%.

PROPERTIES | CNBM-NFG1 | CNBM-NFG2 | CNBM-NFG3 |

Medium Carbon | High Carbon | High Pure | |

Carbon | 85-95% | 96%-99% | 99.9% |

Mesh | 45 μm-500 μm (325mesh-35mesh) | ||

V.M. | ≤4% | ||

Moisture | ≤0.5% | ||

Color | Black Shiny, | ||

Appearance | Flake | ||

Packaging & Shipping

Packaging: 1.25MT jumbo bags or 1MT jumbo bags

Delivery details: according to customers’ requirements

Applications

1.Used as release agent lubricant in the production of chemical industrial catalyzer.

2.Used as high temperature resistance lubricant base material,erosion resistance lubricant base material.

3.Used as powder metallurgy release agent and metal alloy material.

4.Suitable for making graphite refractory bricks.

Company information:

China National Building Materials Group is a stated -owned enterprise in charge of administrative affairs in China buiding materials industry.Established in 1984 CNBM is a large group corporation of building materials with total assets of 25 billion and a total stuff of 30000 CNBM now owns 200 subordinating firms of solely owned and joint-venture companies.

- Q: For refractory, what is critical particle size? Thank you.

- It also refers to the largest particle size of aggregate!

- Q: I wanna ask about the building insulation materials fire rating?

- In China, the main external insulation materials are divided into level A, level B1, level B2 and level B3. According to the current "Combustion Performance Classification Method of Building Materials", level A thermal insulation material is incombustible material and inorganic insulation material. However, there are few level A thermal insulation material on the current market, only glass wool, rock wool board, foam glass and vitrified micro bead. However, compared with level A insulation material, the organic insulation materials are popular in the market. Level B insulation material can be divided into three levels, level B1 is flame-retardant, level B2 is flammable, and level B3 is flammable. Level B1 nonflammable thermal insulation material is determined by the fire endurance of the material, in addition, different parts of material is divided differently! More common is EPS / XPS insulation boards which have added flame retardant through special treatment. B2 level of combustible insulation materials, common to EPS expanded polystyrene foam insulation board and XPS board, that is, we often say that the general board. The ignition point of this material is very low, and it will release a large amounts of harmful gases in the combustion process. level B3 flammable insulation material is a kind of thermal insulation material which mainly made of polyphenyl foamed. Since this material is highly flammable, it has been eliminated. Civil construction insulation materials, popular building insulation materials in China's current market are mainly made by three organic foam, such as EPS (molded polystyrene board), XPS (extruded polystyrene board) and PU (polyurethane)

- Q: How is the grading of the level A new material fire insulation material?

- The standard to distinguish level A and level B is the different fireproofing coefficient. The level A is non-combustible. The level B is divided into B1, B2 and B3. B1 is flame retardant, B2 combustible and B3 flammable. The level A is commonly phenolic aldehyde, rock wool, thermal?mortar, foam ceramics, foam glass and foam concrete on the current market. Among the advantages of level A materials, the biggest one is foam concrete currently, also known as foam cement.

- Q: Who knows the fire rating of fire?partition with steel stud?

- Cement board wall of steel stud: it is used for walls with ceramic in kitchens, restroom, disinfect room, etc. If single-sided tile is made, cement pressure plate can be used on one side. Gypsum board is used on the other side. Fire?rating is A1. CaSo4.2H2O is molecular structural formula of gypsum which contains 20% water, crystal water and free water. When 10% water slowly evaporates on the flame surface, there is still 10% crystal water. Itself is grade A fire retardant material. 1 hour. It is in line with the fireproof test standard of national building materials. It can reach up to 4 hours at most.

- Q: How to choose thermal insulation materials for flood heating?

- 1, Select the appropriate floor material suitable for radiant floor heating. The floor radiant heating system mainly transfer heat through the ground concrete and the ground material to the room. Therefore in the heating season the ground material will always be heated during heating season. Therefore, it is better to choose stone materials and compround floor plate insensitive to tenmperature change with good heat dissipation and functions. Currently, wood floor is not suitable for the ground radiant heating system. 2, choose the pipe with anti permeability performance. Plastic floor heating pipe itself has a certain air permeability, if oxygen penetrates in it is prone to oxygen erosion and system's mental device will be eroded, resulting in the risk of leakage. Therefore in order to ensure the reliable operation of the heating system, the selected pipe must have anti oxygen permeation performance, and meet the standard stipulated by the DIN4726 oxygen permeation quantity: and be less than 0.1mg\L.d at 40 C.

- Q: who knows the fire resistant level of fireproof gypsum board ?

- The most commonly used ceiling decoration materials rates B1, including gypsum board, fibrous plaster, cement particle board, mineral wool sound-absorbing panels, glass wool decorative acoustic?panel?absorber, perlite decorating acoustic board, nonflammable plywood, nonflamable medium density fiberboard, mineral wool decorative board, flame retardant wood, aluminum foil composites, flame retardant phenolic plywood, aluminum foil glass fiber reinforced plastic composite materials. The fire gypsum board fire rating can reach A. Of course, many of the suspended ceiling gypsum board of inferior quality rates below B1. plasterboard is non-flammable B1 level products. There are introductions in Fireproof Specification of National Standard Building Interior Decoration Design. plaster board mounted on steel stud can be used as A level decoration materials. in accordance with the national fire safety rules on fire durance of walls and ceilings and other components. we can not simply say whether a piece of gypsum board can meet the requirements.

- Q: How is refractory material made?

- It is made from yellow mud and water.

- Q: What are fire resistant level standards of class A fire resistant door?

- Situations under which fire endurance should at least meet class A fire resistant door standard: In basement, the fire door for room where the stored combustibles average weight exceeds 30kg/㎡; in partition basement, the fire door for partition of room where the stored combustibles average weight exceeds 30kg/㎡; in high building, the fire door for equipment room of automatic fire extinguishing system, fan room and air-conditioner room; in boiler room, transformer?cabin, diesel?generator room(other dangerous rooms), the fire door in firewall. These places are special and need high security, so they need to meet the standard of class A fire resistant door. What is class A fire resistant door? New Standard for Fire Door GB12955-2008 provides that class A fire resistant door thermal insulation and refractory integrity should be no less than 1.5 hours. In other words, the key of fire door grade is the fire-resistant time. Class A fire resistant door size: class A fire resistant doors have many sizes, and can be customized according to the needs of customers. For example, the size of some fire doors of the diesel generator room is large, while the size of fire doors of basement storing combustibles is small. So the size of class A fire resistant door is also different. Usually Xinduo will take this into account, produce class A fire resistant door with various sizes and can customize according to customer requirements. Class A fire resistant door standard: as is mentioned above, for class A fire resistant door standard, the key is the fire resistant time, no less than 1.5 hours. In texture, class A fire resistant door standard is manifested in the firm joint, uniform distribution of solder joints and smooth surface coating. It has also set fireproof sealing strip which should be straight.

- Q: What's the commonly used refractory material for ladle?

- Commonly used types of refractory material for ladle are as follows: high-alumina brick, clay brick, magnesia-carbon brick, aluminum carbon brick, magnesia chrome brick, spinel brick, corundum brick, high alumina castables, aluminum silicon carbide carbon castables, refractory castables for ladles, magnesium castables, magnesia chrome spray coating, dry vibration materials, etc. Hope it's helpful for you!

- Q: What's the fire endurance of A grade fireproof glass curtain wall?

- The following is fire endurance of A class fireproof glass curtain wall. Fire endurance of the fire window: A class fire window: no less than 1.2h; B class fire window: no less than 0.9h; C class fire window: no less than 0.6h. Technical requirements: 1. Materials and fittings: (1) Window frame should adopt the steel frame or wood frame with certain strength so as to guarantee the integrality and stability of the fitting; (2) Steel frame and mound layer can choose the galvanized steel sheet or stainless steel sheet. Its selection standard is in line with provisions of Article 5.1 in GB12955 "General Technical Requirements on Steel Fire Doors"; (3) Selection standard of wood frame and mound layer should be consistent with the provisions of Article 5.1.1 in GB14101 "General Technical Requirements on Wood Fire Doors"; (4) Filler material inside the steel frame and wood frame should be incombustible material; (5) Fireproof glass can choose the qualified product with no influence on the fire resistance test of the fire window, and its light transmittance should be no less than 75% of that of the ordinary sheet glass with the same layers; (6) Sealing material between the frame and the fireproof glass should use flame retardant material which can play the role of fire prevention and smoke insulation in case of fire. Hope it's helpful for you.

Send your message to us

Raw Materials for Refractory:Flake Graphite with Good Quality and Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t

- Supply Capability:

- 5000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords