Fireclay Brick - Standard Size/Standard Dimensions

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 2000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High alumina fireclay Brick

High alumina fireclay Brick for Heating Furnace is a kind of insulation material adopting organic matter as ignition loss substance in order to increase the porosity of refractory, which has such advantages as high porosity, small volume density, good insulation effect, high mechanical intensity, small thermal conductivity and long service life. For various industrial kilns & furnaces, it is a kind of essential refractory for energy saving and temperature preservation.

This series of High Alumina fireclay Brick for Heating Furnace are made of selected high alumina bauxite, kaolin caly, hollow microsphere as the mian material.By shaping at high pressure and sintering at high temperature.

Fireclay brick is shaped refractory product.It is made from flint clay clinker and binder , Through high heat sintering. The Al2O3 content range from 28% to 48%.The refractoriness range from 1580°C to 1750°C(SK-30.SK-32.SK-34.SK-35).

Product Applications:

High alumina fireclay Brick are ideal for use in the below applications

Furnaces of metallurgy industry, heat treatment furnace

Furnaces of chemical industry and construction industry.

Furnace of incineration of garbage, recirculating fluidized bed furnace

Standard sizing: 230 x 114 x 65 mm others up to the client

Product Advantages:

CNBM has success in its Fireclay brick due to their cost-effectiveness and excellent insulating properties. CNBM also has experience in ceramic fiber blankets application and would like to assist you in product selection, system design, and installation techniques.

Main Product Features:

High refractoriness,High-temperature endurable .

Good corrosion resistance.

Good spalling resistance and wear resistance.

Good thermal shock resistance.

High mechanical strength.

High-temperature creep rate is low.

Good volume stability at high temperature.

Product Specifications:

ITEM | UNF42 | UNF46 | ZGN42 | RN40 | TDL45-12 |

Refractoriness, ℃ | 1730 | 1750 | 1750 | 1730 | 1760 |

Bulk Density, g/cm3 | 2.15 | 2.25 | 2.3 | 2.15 | 2.37 |

Apparent Porosity, % | 22 | 20 | 15 | 24 | 12 |

C.C.S, Mpa | 30 | 35 | 58 | 28 | 68 |

Refractories Under Load (0.2Mpa),℃ | 1400 | 1420 | 1450 | 1430 | 1500 |

Reheating Linear Change, % | 1400℃x2h 0.1~-0.4 | 1430℃x2h 0~-0.1 | 1450℃x2h 0~-0.2 | 1350℃x2h 0~-0.3 | 1450℃x2h -0.1~+0.05 |

Al2O3 Content , % | 42 | 46 | 42 | 40 | 45 |

Size :

Common sizes

Straight type | Arch type | Wedge type |

L×W×H (mm) 230×114×65 230×114×75 230×114×32 220×110×60 220×110×50 220×110×40 220×110×30 | L×W×H/h (mm) 230×114×65/55 230×114×65/45 230×114×65/59 220×110×65/50 220×110×75/65 220×110×60/40 | L×W×H/h (mm) 230×114×65/55 230×114×65/45 220×110×75/65 220×110×60/40 |

Other sizes according to customer requirements | ||

FAQ:

Q1: How about your factory’s annual production capacity?

A1:CMAX annual production is about 310,000Tons.

Q2: How many production lines of your factory?

A2:CMAX has 26 production lines, including eight silicon bricks lines, and each one of mullite brick, high alumina brick, insulating brick and monolithics line.

Q3:How large the scale of your factory?

A3: CMAX covers almost 200,000 Square meters, including plant area of 180,000 square meters.

Q4: What’s your factory’s product scope?

A4:CMAX main products are: refractory for hot blast stove, refractory for coke oven, refractory for glass kiln, refractory for carbon calcining furnace, refractory for acid pickling line, refractory for cement kiln, refractory for blast furnace, refractory for nonferrous metal furnace, and basic refractory raw materials.

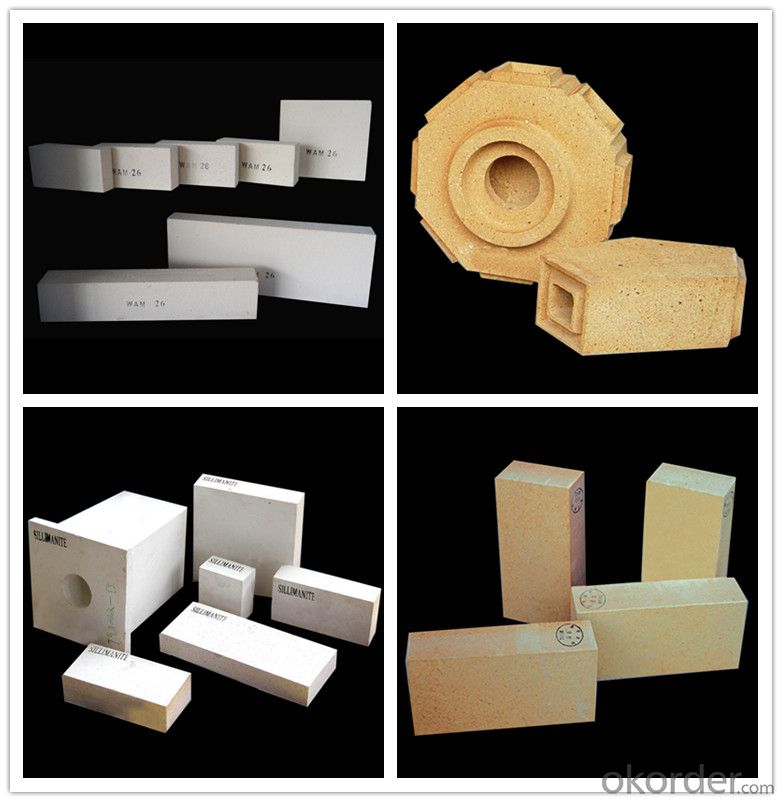

Product Picture

Produce Processing

Crushing

In this stage massive raw materials which have been stored, are ground and classified into proper sizes, making them easier to shape.

Mixing

The prescribed size of ground raw material is weighed and mixed into a designated amount of water and forming agent.

Shaping

The mixture is then poured into a mold to form shapes, and the pressure is high.

Drying

In this stage water is removed from the shaped bricks. This helps preventing the bricks from deforming or cracking which may result due to the rapid evaporation

Firing

This is the most crucial process in refractory manufacturing. The modeled bricks are fired at high temperature to complete their thermochemical reaction so that they do not deform.

Inspection

The bricks' physical and chemical properties are inspected very carefully by rigid quality management procedures.

Packing shipment

We guarantee efficient delivery every time.

Packing

We also supply (Click on following picture if interested):

- Q: what effect does big mortar joints of the boiler refractory brick have on the boiler?

- The ventilation leakage。 Now the larger boilers are generally used refractory pouring material one-time pouring, the arch is easy to collapse . 2, shrinkage and expansion of brick will make the bricks fall. 1, do not use the refractory brick. too large seam will effect the tightness of furnace wall , and the water wall is easy to form dew and be corroded and to leak smoke.

- Q: What are the weak points of clay bricks?

- SiO2 and Al2O3 in clay bricks form eutectic, low melting point silicates with impurities during sintering, and are surrounded by mullite crystals. Clay brick belongs to weak acid refractory products, it can resist acid slag and acid gas corrosion, and its resistance to alkaline material is a little worse. The thermal performance of clay brick is good, it is fast and cold. The clay brick refractory brick and be roughly the same, up to 1690~1730 DEG C, but the load softening temperature is 200 degrees Celsius above the low brick. Because clay bricks contain crystalline Mullite with high refractoriness, they contain nearly half of the amorphous glass phase of low melting point.

- Q: What are the disadvantages of sintered clay bricks?

- Fired common bricks are made of clay, shale, coal gangue or fly ash as raw materials, and the solid or hole ratio after roasting is not greater than the specified value, and the size of the bricks meets the requirements.

- Q: What are the differences between sintered bricks and refractory bricks?

- Sintered bricks belong to a type of refractory bricks.

- Q: The renewal of refractory brick internal the lime kiln belongs to overhaul. In the absence of production, are the replacement of valve and sporadic projects also considered overhauls? Or routine maintenance!

- The replacement of refractory brick for lime kiln is definitely a major overhaul, and the replacement of the valve and sporadic items can only be regarded as routine maintenance.

- Q: What are needed to make refractory bricks with micro silica?

- Micro silicon powder is used in mortar and concrete, the ore-smelting electric furnace produces a large amount of strongly volatile gases SiO2 and Si, bridges, seaports. It is ferroalloy. When smelt ferrosilicon and industrial silicon (metallic cilicon), micro silicon power is also called silica fume or condensed silica fume, dam, gas emissions and air condensate and deposit by rapid oxidation, water conservancy, airport runway, tunnel, high-rise buildings, subway, railway, highway and culvert. Application fields of silicon power are cement concrete pavement and mine roadway anchor reinforcement and etc.

- Q: Which is the higher price of concrete solid brick and MU15 fired common brick (non clay brick)?

- The price of concrete solid bricks and the price of MU10 bricks are on the same level, and the difference will not exceed two cents a penny. It should be MU15 sinter ordinary brick is more expensive.

- Q: What type of refractory brick won't deform or crackbe for a long time in the temprature of about 1600 degrees?

- 1. , mullite poly light ball brick type, andalusite brick type: MJ-1600 MJ-1700 the temperature is higher than 1600 C. 3, the refractory bricks that won't deform or crack in the 1600 degrees Celsius for a long time includs the following several commonly used bricks: GMZ-80 GMZ-75 the temperature is higher than 1650 DEG C, 2, corundum mullite brick type

- Q: Do refractory bricks resist corrosion and sulfur?

- The refractory brick just plays the role of resisting high temperature and insulating heat.

Send your message to us

Fireclay Brick - Standard Size/Standard Dimensions

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 2000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords