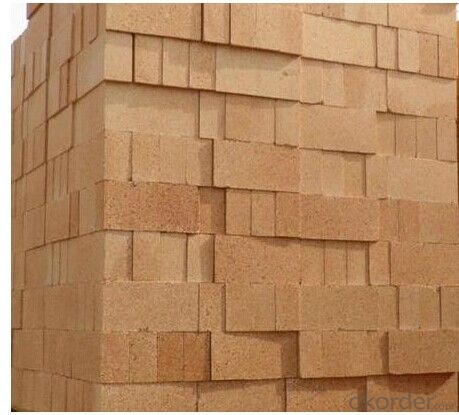

Fireclay Brick - Common Fire Clay Bricks

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1.high density,high refractoriness

2.high thermal shock,competitive price

3.low porosity,heat resistance

Application: they are wildly used in various furnaces, especially suitable to the middle and low parts of regenerator in glass furnaces.

Specification:

Common fireclay products

Product Index | Common Fireclay Products | |||

DN-10 | DN-12 | DN-15 | DN-18 | |

AL2O3 % ≥ | 45 | 45 | 42 | 42 |

Fe2O3 % ≤ | 1.00 | 1.20 | 1.65 | 1.80 |

Bulk Density≥ g/cm3 | 2.40 | 2.35 | 2.30 | 2.25 |

A.P. % ≤ | 10 | 12 | 15 | 18 |

C.C.S (Mpa) ≥ | 70 | 65 | 60 | 48 |

Refractoriness ≥ °C | 1750 | 1750 | 1750 | 1750 |

Reheating Linear Change% | 1400°C×2h -0.1~+0.05 | 1400°C×2h -0.1~+0.05 | 1400°C×2h -0.2~0 | 1400°C×2h -0.4~0 |

0.2Mpa Refractoriness under loadT0.6 ≥ °C | 1500 | 1470 | 1450 | 1400 |

Refractory brick is dense shaped refractory material. With high refractoriness and mechanical behavior under high temperature, refractory brick is the necessary material of high-temperature services, mainly used for industrial furnaces and kilns and thermal equipment.

Refractory brick has wide applications, mainly used in metallurgy, construction(cement and glass), petroleum, chemical industry, electric power and machine building.

- Q: There are various refractory materials inside many kilns such as refractory brick, what is the role of masonry of these refractory materials?

- Heat insulation

- Q: The brick and ordinary clay brick which is expensive

- Of course expensive materials sintered clay brick, sintered clay brick fired common clay, shale and shale and coal gangue as raw materials by high temperature firing,

- Q: What are required for high temperature refractory bricks?

- Volume density, aluminum content, soft bearing, thermal shock

- Q: Shale brick and clay brick? Answer before you know it

- The clay brick with clay, shale, coal gangue as raw materials, crushing, mixing kneading with artificial or mechanical pressing, sintering and building bricks after drying at 900 centigrade temperature by oxidizing flame firing.

- Q: What building materials can take the place of clay bricks?

- Foam concrete block is a new type of environmental protection material, the state will avoid the wall change fund, and the red brick construction units must be turned over to 8 yuan per square metre of the wall change fund.

- Q: What are the differences between sintered bricks and refractory bricks?

- Easily weathered. There is no obvious difference in the usage between fired pavingbricks and refractory bricks; sintered bricks are generally used for residential road and landscape engineering, they do not fade; refractory bricks are used for all kinds of kiln constructions in plant: It is not anti-freeze (when the temperature is below the zero degree, the brick will easily "blister" in the saturated state), the reasons are high compressive strength and high temperature zone' heat insulation and so on. Fired pavingbrick is a powerful vacuum extrusion type. Fire suppression road brick is high temperature furnace brick, which is not suitable to be used as road brick. Its characteristics are: Wear resistance and freeze-thaw resistance (the anti freeze-thaw cycle of brick is more than 50 times in saturated state), non weathering, sidewalks, short service life. Sintered brick belongs to the building material, refractory brick belongs to the industrial kiln material, which is easy to moss

- Q: Should refractory cement hang inner core when use carbon steel pipe make water heating hearth by self?

- I think it shouldn't. There is no refractories used for circulation pipe inside the boiler, and there is how long distance between pipe and coal fire

- Q: What is the meaning of the new type of dry rotary kiln refractory brick 620,320?

- 20 stands for that the length of the brick is 20CM, there is only a kind of 620 brick for masonry. Simply say: 1. 620 and 320 these two specifications of bricks are needed simultaneously if it is 4 meters kiln that should be built. When the diameter of the kiln is 6M. Other specifications of kiln can be built by useing these two kinds of bricks in different proportions. 3M kiln can be built only by using 320 brick, its proportion of use is 16. 3 stands for kiln's diameter

- Q: What are the differences and uses of non clay bricks, non clay bricks and ordinary red bricks?

- Non clay brick clay brick walls can be completed, insulation and so on, often also can have some characteristics, such as light weight, heat insulation, heat absorbing ability better and so on.

- Q: How to make the adhesion between refractory brick and the inner wall of the boiler more firm?

- The hook structure, or masonry concrete beams.

Send your message to us

Fireclay Brick - Common Fire Clay Bricks

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords