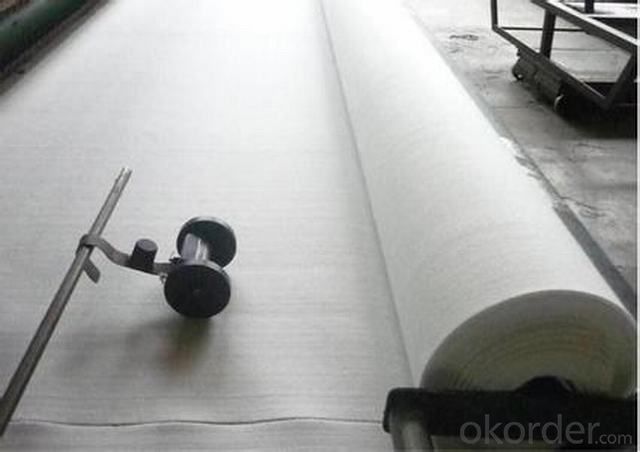

Film Géotextile Short Fiber Nonwoven Geotextile for Geotechnical Engineering

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 1500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Functions of Non-woven Geotextile for Geotechnical Engineering:

1.Separation

The isolation of the railway dregs and the roadbed, roadbed and the soft base, surface of the airdrome and parking lot and the groundsill, different dam materials. It isolates the soil and the gravel of two kinds different.granule pathway from the groundsill or other buildings.

2.Reinforcement

The highway, railway, soil-stone dam, breakwater, airport, backfill soil of retaining wall, slope protection, etc in which distributes the earth stress, prevents the side-displacement of the earth body and improves the earthbody stability.

3.Protection

It prevents the bank from being washed out, protects the bank and the bottom, prevents the water and soil from being washed away

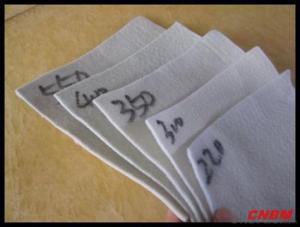

Technical Data Sheet of Short fiber Nonwoven Geotextile for Geotechnical Engineering:

Item | Art No. | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 |

Unit weight, g/m2 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 800 | |

Weight tolerance, % | -8 | -8 | -8 | -8 | -7 | -7 | -7 | -7 | -6 | -6 | -6 | |

Thickness, ≥mm | 0.9 | 1.3 | 1.7 | 2.1 | 2.4 | 2.7 | 3.0 | 3.3 | 3.6 | 4.1 | 5.0 | |

Break strength, ≥kN/m | 2.5 | 4.5 | 6.5 | 8.0 | 9.5 | 11.0 | 12.5 | 14.0 | 16.0 | 19.0 | 25.0 | |

CBR burst strength, ≥kN | 0.3 | 0.6 | 0.9 | 1.2 | 1.5 | 1.8 | 2.1 | 2.4 | 2.7 | 3.2 | 4.0 | |

Tear strength, ≥kN | 0.08 | 0.12 | 0.16 | 0.20 | 0.24 | 0.28 | 0.33 | 0.38 | 0.42 | 0.46 | 0.60 | |

Width tolerance, % | -0.5 | |||||||||||

Break elongation, % | 25-100 | |||||||||||

EOS O90, mm | 0.07-0.2 | |||||||||||

Vertical permeability coefficient, cm/s | K×(10-1-10-3)K=1.0-9.9 | |||||||||||

- Q: What are the considerations for geotextile installation?

- Some considerations for geotextile installation include site preparation, proper anchoring techniques, selecting the appropriate geotextile material for the specific application, ensuring proper overlap and seam strength, and proper maintenance and inspection of the installed geotextile.

- Q: Can geotextiles be used for erosion control in riverbanks?

- Yes, geotextiles can be used for erosion control in riverbanks. They are commonly employed to stabilize soil, prevent erosion, and enhance vegetation growth in riverbank applications. Geotextiles provide reinforcement, filtration, and drainage capabilities, making them effective in reducing soil erosion and maintaining the stability of riverbanks.

- Q: Performance and Application of Impervious Geotextile

- Anti-seepage geotextile has excellent water permeability, filterability, durability, can be widely used in railways, highways, sports museum, dams, hydraulic construction, then hole, coastal beach, reclamation, environmental protection and other projects. Mainly staple acupuncture non-woven geotextile and split film woven geotextile. Anti-seepage geotextile function: 1. The use of geotextiles good permeability and water permeability, so that water through, so as to effectively remove the loss of sand. 2. Geotextile has a good water conductivity, it can form a drainage channel within the soil, the soil structure of the excess liquid and gas efflux. 3. Using geotextile to enhance the soil tensile strength and resistance to deformation, enhance the stability of the building structure to improve the quality of soil. 4. Effective focus will be concentrated diffusion, transmission or decomposition, to prevent soil damage by external forces. 5. to prevent the upper and lower gravel, soil and concrete mixed between. 6. Mesh is not easy to plug - due to the formation of amorphous fibrous tissue structure and strain and mobility. 7. High permeability - under the pressure of soil water, can still maintain a good permeability 8. Corrosion resistance - to polypropylene or polyester and other chemical fiber as raw materials, acid and alkali, no corrosion, no moth, antioxidant. 9. Construction is simple - light weight, easy to use, simple construction. Anti-seepage geotextile characteristics High anti-puncture strength, large coefficient of resistance to aging performance, to adapt to the environmental temperature range Excellent excellent anti-drainage performance for water conservancy, chemical, construction, transportation, subway, tunnel, garbage disposal and other projects

- Q: How do geotextiles contribute to the efficiency of drainage systems?

- Geotextiles contribute to the efficiency of drainage systems by providing two main benefits. First, they act as a filter to prevent soil particles from clogging the drainage pipes or systems, allowing for a consistent flow of water. Second, they help to distribute the water evenly across the entire drainage area, improving the overall effectiveness of the system.

- Q: What glue glue is used at the seams of the impervious geotextile

- What glue glue is used at the seams of the impervious geotextile

- Q: What are the specifications for geotextiles in gas venting projects?

- The specifications for geotextiles in gas venting projects typically include factors such as the required permeability, strength, and durability. The geotextile should have a high porosity to allow efficient gas flow while preventing the passage of fine particles. It should also possess sufficient tensile strength and puncture resistance to withstand installation and long-term exposure. Additionally, UV resistance and chemical compatibility with the surrounding environment are crucial considerations to ensure the geotextile's longevity and performance in gas venting projects.

- Q: Can geotexters cover grass seeds?

- Geotextile is anti-puncture which grass can not grow out, you can use the vegetation bag ah

- Q: What is the meaning of geotextile anchoring?

- Geotextile anchorage: is the geotextile in the construction of civil engineering construction in the slope of the fixed, to prevent the geotextile movement.

- Q: Can geotextiles be used in underground drainage systems?

- Yes, geotextiles can be used in underground drainage systems. They are commonly used to improve the filtration and separation functions of the system by preventing soil particles from clogging the drainage pipes. Geotextiles also provide additional stability to the system and enhance its overall performance.

- Q: Permeable geotextile price how much

- 2 to 4 yuan range

Send your message to us

Film Géotextile Short Fiber Nonwoven Geotextile for Geotechnical Engineering

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 1500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords