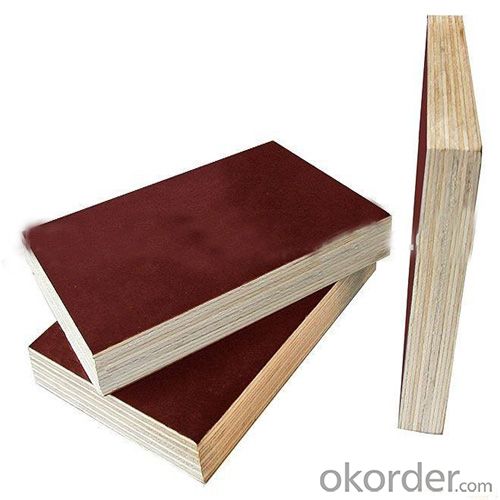

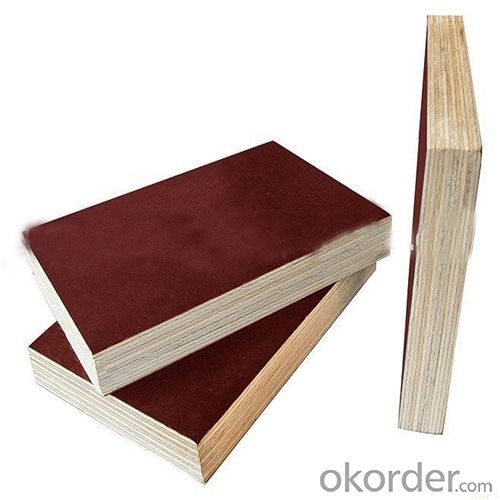

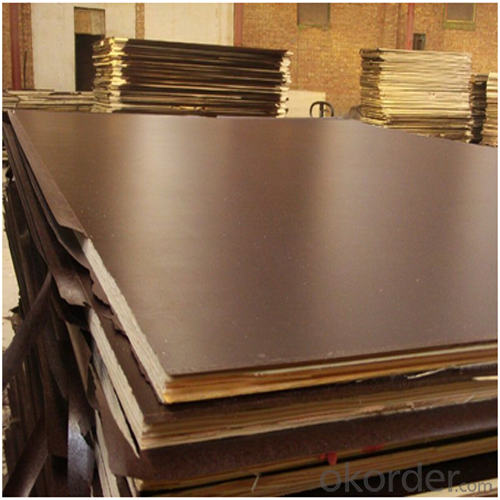

13 layers Film Faced Plywood with Double-sided Decoration

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 22 m³

- Supply Capability:

- 9000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Details:

· Type: Plywoods

· Place of Origin: Shandong, China (Mainland)

· Usage: Outdoor

· Grade: First-Class

· Main Material: Poplar

· Formaldehyde Emission Standards: E1

· Plywood Type: Veneer Boards

· Veneer Board Surface Finishing: Double-Sided Decoration

· Veneer Board Surface Material: poplar

· Size: 1250*2500mm

· Glue: MR,WBP,MELAMINE

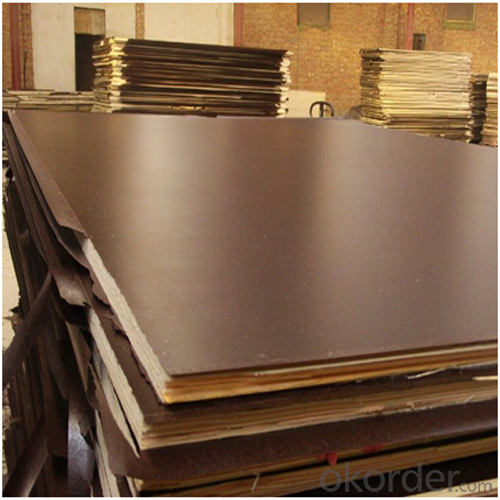

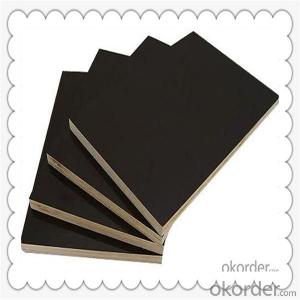

· Film: brown, black

· Thickness: 9-35mm

· Certification: ISO9001

Packaging & Delivery:

Packaging Details: | Inner packing: inside pallet is covered with 0.2mm plastic bag; Outer packing: by pallet, wrapped in carton, reinforced with iron belt, and seaworthy for shipping by sea |

Delivery Detail: | within 15 days after receiving prepay or against origin L/C |

Product Specifications:

13 layers film faced plywood

Core: poplar and hardwood plywood

Glue: WBP, melamine, MR

Film: Brown, black film

FILM FACED PLYWOOD with good quality and competitive price

Specification | 1220*2440mm;1250*2500mm |

Thickness | 9-35mm(thickness tolerence: +/-0.5mm) |

Core | poplar ,birch ,hardwood, combi core plywood |

Film | Chinese brown and black film or as your request |

Glue | WBP, MLM, MR |

Grade | AAA grade |

Package | Inner packing: inside pallet is covered with 0.2mm plastic bag; |

Deliery time | within 15days after receiving prepay or against origin L/C |

Addition | Discount will be allowed for a big order |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce some wood products according to customers request?

A4: Yes, we can produce wood products according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, if needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

Product Show:

- Q: The current market price is how much money a square meter?

- Polystyrene is a good point of its own do not have to consider the high temperature side of the polystyrene composite board cost-effective relatively high cost

- Q: What is the meaning of the bulk density of double-sided color steel polyurethane panels?

- Bulk density of polystyrene foam board should be ≥18kg / m; Polyurethane double sided steel plate Metal surface sandwich panel metal surface sandwich panel metal surface sandwich panel metal surface sandwich panel 1 product definition product definition product definition product definition metal surface sandwich panel refers to the upper and lower layers of metal sheet, the core material is a certain stiffness Insulation materials, such as rock wool, rigid foam, etc., in a dedicated automated production line composite bearing capacity of the structural plate, also known as "sandwich" board. Metal surface sandwich panel should be considered when the main technical indicators of metal surface sandwich board should be considered when using the main technical indicators of metal surface sandwich board should be considered when using the main technical indicators of metal surface sandwich board should be considered when the main Technical indicators :::: bonding performance, peel performance, bending load capacity, thermal conductivity, fire resistance, combustion performance. Double-sided color steel rigid polyurethane plate its bulk density of 35 ~ 40kg / m3, thermal conductivity: 0.018-0.023, low thermal conductivity, thermal performance.

- Q: Hanging plate, color plate, sandwich panels, pressure plate the same?

- Sandwich panels and Caigang sandwich panels is one thing, are double-color steel plate folder folder insulation material, food production workshop with sandwich panels can

- Q: We want to build the activities of the board room is used as a dormitory, what materials used sandwich board good? What is the price of polystyrene board and rock wool board? As a dormitory board room in the height of the national standard? How high should it be?

- Mainly to see the use of activities, fire or rock wool sandwich board is good

- Q: Sided 0.8 thick stainless steel plate extruded board sandwich panels there are production

- Good insulation or polyurethane

- Q: Sandwich panels on both sides of the metal, 50mm thick price

- Both sides of the metal have different thickness, the thickness of different, the price is different Oh! Thickness generally 50mm, 75mm, 100mm these three. We have a home in Jiangxi Baoyuan Caigang, they specializing in the production of sandwich panels, Caigang tiles, galvanized sheet, C-beam, in the color steel structure industry is very experienced, Jiangxi Baoyuan Caigang products sell well throughout the country, won the The majority of customers praise.

- Q: Thickness of rock plate sandwich panels Drawings are written on the F50 color steel rock wool sandwich panels, I would like to ask F50 is the meaning of God, can represent the thickness of it? I asked whether the F50 can represent the thickness of 50 or just a model, in fact, the thickness of 100?

- I have a solution to it. F that Fire, should be the brand is Lokewei it, because Lokowei have 50F and 50C, there are 75F and 75C models, F is the fire board, C said the ordinary version, but 50 can not represent the thickness, because our Offer range, 50F and 50C have 50,80,100,120 mm ... and so the thickness, so 50 can not be the thickness of the thickness of the need for additional set. PS: 50 in Lokovo and intensity (density) have a relationship .50 strength is not high strength of 75. The higher the thickness the thicker the thickness

- Q: 50mm thick roof color steel sandwich board price is generally how much money a m2?

- Depends on the thickness of the color plate, different thickness of the color plate is not the same. For example: color plate thickness: 0.28mm thick: 0.2mm need 40 yuan / m.

- Q: The main sheet of glass wool cotton sandwich panels

- 1. Surface material / floor (color coated plate, galvanized sheet, stainless steel plate, aluminum foil paper, PVC, plywood, etc.) 1.1 Introduction of various sheet properties (1) color coated board The substrate is hot-dip galvanized or galvanized sheet, but also the use of electro-galvanized substrate, the surface of the paint is not bent off; (Two coated two) or the existence of quality problems such as loose edge serious, the middle loose heart, leakage coating, large serrated edge, serious Oval, uneven and so can not be used for the production of composite panels. (2) galvanized sheet Poor bonding is sometimes not handled well and needs to be handled. (3) stainless steel plate Good corrosion resistance, toughness difficult processing; bonding effect is sometimes bad, need to deal with. (4) aluminum foil Reinforced aluminum foil is a kind of aluminum foil and kraft paper folder between the glass fiber reinforced plastic composite material, with fire-retardant, fire and other functional characteristics, and beautiful, durable, is a new generation of insulation, insulation, sound insulation ideal supporting insulation The

- Q: Ultrasonic cleaning machine cleaning Caigang sandwich panels the most basic quality conditions?

- The advantages of more professional cleaning machine work in the practice of the pursuit of a higher level of progress and development, improve the actual production efficiency of the guarantee, the most important thing is to really clean the product to achieve better cleaning results, to ensure greater advantages Cleaning conditions to achieve the purpose of cleaning, cleaning rate is the most important high-quality assurance.

Send your message to us

13 layers Film Faced Plywood with Double-sided Decoration

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 22 m³

- Supply Capability:

- 9000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords