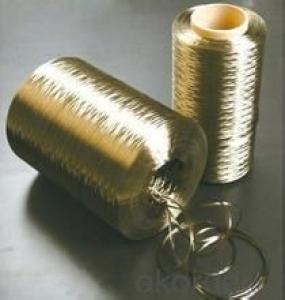

Fiberglass Roving Roll 50-Lb - E Glass Fiber Woven Roving for FRP Usage

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 16000 kg

- Supply Capability:

- 160000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

E-Glass Woven Rovings are bidirectional fabric made by interweaving direct rovings.

E-Glass Woven Rovings are compatible with unsaturated polyester, vinyl ester, epoxy and phenolic resins.

E-Glass Woven Rovings are a high-performance reinforcement widely used in hand lay up and robot processes to manufacture boats, vessels, plane and automotive parts, furniture and sports facilities.

Warp and weft rovings aligned in a parallel and flat manner, resulting in uniform tension

Densely aligned fibers, resulting in high dimensional stability and making handling easy

Good moldability, fast and complete wet out in resins, resulting in high productivity

Good mechanical properties and high strength of parts

Product Specifications

Property | Area Weight | Moisture Content | Size Content | Width |

(%) | (%) | (%) | (mm) | |

Test Method | IS03374 | ISO3344 | ISO1887 | |

EWR200 | ±7.5 | ≤0.15 | 0.4-0.8 | 20-3000 |

EWR270 | ||||

EWR300 | ||||

EWR360 | ||||

EWR400 | ||||

EWR500 | ||||

EWR600 | ||||

EWR800 |

FAQ

Q: Can you accept sample order?

A: Yes, we accept samples with little and reasonable charge

Q: What is your MOQ?

A: Normally,4 rolls.

- Q: Does toughened glass and glass?reinforced?plastics are the same?

- It should be said that they are the same material.

- Q: What are the advantages of glass fiber reinforced plastic antennas? What's the difference between an ordinary antenna and an ordinary one?

- SMC and its molded products as a new glass fibre reinforced plastics, glass steel, the processing methods can be divided into: hand molding, injection molding, paste pultrusion, winding molding, resin transfer molding, molding and other kinds of processing methods.

- Q: What are the components of the GRC cement component?

- The thermal insulation properties are so good that they can pass through the bricks with its thickness over 570mm, alkali resistant glass fiber chopped yarn,150 tons discharge valve and so on. Bulk cement silo is a cylindrical structure, welded by guardrail and pressure relief valve. The bottom is composed of four supporting legs for sustaining the whole silo. Cement component use lightweight foam concrete thermal insulation board so that they don't need to build external wall foam insulation layer.Cement component is composed of dust catcher and high and low material level meter with 100 tons and 500 tons specifications. The experimental results shows that the house with the use of this product can greatly reduce the heating and cooling power. Bulk cement silo meets industry standards.

- Q: How to make GRC line?

- The basic composition of GRC materials are cement, sand, fiber and water, in addition to polymer, additives used to improve the later performance of the materials. Cement: Usually the cements used in GRC are mainly rapid hardening sulphoaluminate cement and low alkalinity sulphoaluminate cement, Portland cement and white Portland cement. Fiber: The fiber in the GRC material must be alkali resistant glass fiber, which include alkali resistant glass fiber roving, chopped glass fiber yarn, alkali resistant glass fiber mesh cloth. European and American countries require the zirconia content in the glass fiber should not less than 16.5%. The polymer: the polymer usually added is acrylic emulsion, also named acrylate copolymer emulsion. Additive: Usually we selectively added superplasticizer, superplasticizer, retarder, early strength agent, antifreeze, anti rust agent and other additives containing products. When there is the steel reinforcement or steel embedded parts, do not use calcium chloride based additives. Other materials: We can selectively use fire. The basic composition of GRC materials are cement, sand, fiber and water, in addition to polymer, additives used to improve the later performance of the materials. Cement: Usually the cements used in GRC are mainly rapid hardening sulphoaluminate cement and low alkalinity sulphoaluminate cement, Portland cement and white Portland cement. Fiber: The fiber in the GRC material must be alkali resistant glass fiber, which include alkali resistant glass fiber roving, chopped glass fiber yarn, alkali resistant glass fiber mesh cloth. European and American countries require the zirconia content in the glass fiber should not less than 16.5%. The polymer:

- Q: Does centrifugal glass wool is made from glass fiber

- No, the eliminated one in the upper floor does not appear in ten years.

- Q: An introduction to glass fiber geogrid

- It is net?structure material woven through a certain method. In order to protect the glass fiber and improve the overall performance, it is geotechnical base material with excellent performance formed by a special coating treatment process. Glass fiber alkali free twistless roving is the main material of glass fiber geogrid.

- Q: What parts must used fiber reinforced concrete?

- Aircraft runway.

- Q: The manufacturing technique and process of glass fiber

- Glass fiber is glass fiber semi-finished products which uses waste glass of different color after a series of processing complete sets of equipment of the glass fiber with its properties and application is very extensive. Its fineness is 0.03mm to 0.06mm and it is as thin as fine silk and as soft as cotton. It features with high tensil force resistance, white, non-poisoned, non-peculiar smell, high acid and alkali resistance, corrosion resistance, high temperature resistance, good insulation properties and it is widely used in building materials, oil and chemical insulation materials, especially the main material for the development of glass?reinforced?plastics. (1) selection and cleaning of raw materials. 1, all kinds of waste glass are used as raw material with diameter is no less than 3cm, but a lot of organics, mercury and high temperature glass are exception. 2, the cleaning of raw materials: We should put the selected material into cement pool and then add water into it and clean it by broom. After cleaning all the sidement on the surface of glass, you should put it into the other pool for cleaning it again. Finally, you should put it into iron sieve with loophole for seperating from water, then you can use the glass. 3, If there are greasy dirt on the surface of glass, you must press it down firmly, you must keep the crucible holder flat and melt the glass until it turns red so as not to cause electric?shock. You should make the wire wrap around the drum, or it is easy to make the pot break.

- Q: Nominal interpretation of fiber reinforced concrete

- Mix composite materials with random and uniform distribution of short fiber in cement concrete, including steel fiber reinforced concrete. Technical specification for fiber reinforced concrete structures CECS.

- Q: What equipment is needed for teating glass fiber twistless roving?

- Material tester.

Send your message to us

Fiberglass Roving Roll 50-Lb - E Glass Fiber Woven Roving for FRP Usage

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 16000 kg

- Supply Capability:

- 160000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords