Fiberglass Over Fabric Silica Glass Fiberglass Cloth with Vermiculite Coated

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Image:

Product Description & Application:

Vermiculite coated silica Fiberglass cloth is high-temperature resistant products, made by silica glass fiber cloth coat with vermiculite.

Application:

Widely use as heat resistant and ablation-resistant material for rocket, missile and space vehicle;

High-temperature resistant, thermal insulation, refractory material;

Dust collect for high temperature gas;

Liquid filtration & Sound absorbing and thermal insulation for vehicle, motor bicycle;

The thermal insulation protective materials for molten liquid filtration.

Product Capability:

Higher temperature resistant, higher thermal insulation, low thermal conductivity;

Thermal stability and chemical stability;

Good dielectric performance;

High strength and easy to manufacture;

Nontoxic and harmless to the environment.

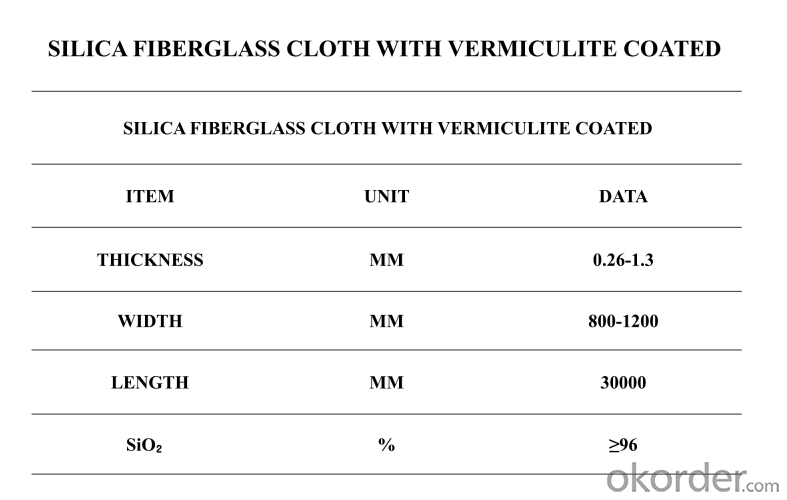

Data Sheet:

Silica fiber products: A kind of inorganic high temperature resistance fiber with the content of SiO₂ higher than 95%, its soften temperature can nearly reach to 1700℃.It can be used in high temperature environment below 900℃ for a long time.

- Q: Can fiberglass fabric be used for reinforcement in 3D printing?

- Indeed, reinforcement in 3D printing can be achieved through the utilization of fiberglass fabric. This material, known for its strength and lightweight nature, presents an excellent option for providing additional structural support to objects produced via 3D printing technology. It effectively reinforces specific areas of a print, such as corners or joints, thereby safeguarding against potential cracking or breaking. The incorporation of layers of fiberglass fabric within the 3D printed object significantly enhances its overall strength and durability. Nevertheless, it is crucial to acknowledge that employing fiberglass fabric in 3D printing necessitates the use of specialized equipment and techniques to ensure proper adhesion and integration with the printed material.

- Q: The thickness of the stone concrete protection layer on the waterproof layer shall not be less than mm.

- Basement roof: non load protection layer generally use C20 fine stone concrete or reinforced concrete, thickness 50~80mm. The road and driving protective layer is determined by design.No roof: General waterproof layer, the above can be 15~25mm cement mortar protection.Upper roof: generally use 40 thick C20 reinforced concrete protection.The purpose of protection, one is to avoid man-made mechanical damage; the two is to prevent climate and UV aging, to prolong the service life; three in the planting roof protective layer to prevent plant roots in different functions using the method of thrust, different protection.

- Q: How does fiberglass fabric perform in static dissipation?

- Fiberglass fabric does not perform well in static dissipation. It is a non-conductive material that tends to accumulate static electricity rather than dissipating it.

- Q: Magnesite material instability made sheds or greenhouse skeleton for a few years

- At present, many manufacturers of magnesite skeleton do not understand what technology utterly ignorant of, and dynamic requirements of raw materials ratio, magnesite modified and other technical problems, the paper presented the formula "only does not have the feasibility! The vast number of friends after the birth of the production of a large number of "problem products", not "brine", that is, water poor performance! In this remind the vast number of ready to receive production of friends should pay special attention to avoid being deceived!

- Q: What are the temperature resistance capabilities of fiberglass fabric?

- Fiberglass fabric has excellent temperature resistance capabilities, making it a popular choice for various industrial and commercial applications. It can withstand high temperatures up to 1000°C (1832°F) without any significant degradation in its mechanical or physical properties. This temperature resistance is due to the inherent properties of fiberglass, which is a composite material made from fine fibers of glass embedded in a matrix of resin or polymer. These fibers have a high melting point and can resist thermal degradation, allowing the fabric to maintain its structural integrity even under extreme heat conditions. Additionally, fiberglass fabric also exhibits good thermal insulation properties, which further enhances its temperature resistance capabilities. Overall, fiberglass fabric is well-suited for use in applications that involve exposure to high temperatures, such as insulation, fire protection, aerospace, automotive, and other industries.

- Q: What kind of fiberglass cloth should be used for keeping the chicken boarding board?

- The rigid polyurethane has low thermal conductivity and high compressive strength. The relatively thin plate can meet the thermal functional requirements of buildings, and the building load can be built.

- Q: Can fiberglass fabric be dyed or printed on?

- Yes, fiberglass fabric can be dyed or printed on. The process of dyeing or printing on fiberglass fabric involves using specialized dyes or inks that are designed to bond with the fibers of the fabric. This allows for vibrant colors and patterns to be applied to the fabric. However, it is important to note that the dye or ink used should be suitable for use with fiberglass and should be able to withstand the specific conditions or applications the fabric will be subjected to, such as high temperatures or exposure to chemicals. Additionally, it may be necessary to use specific techniques or equipment to ensure proper adhesion of the dye or ink to the fiberglass fabric. Therefore, it is advisable to consult with professionals who have experience with dyeing or printing on fiberglass fabric to ensure the best results.

- Q: What are the different types of fiberglass fabrics available?

- There are several different types of fiberglass fabrics available, each with its own unique characteristics and uses. These include: 1. Woven fiberglass fabric: This is the most common type of fiberglass fabric, consisting of tightly woven strands of fiberglass. It is lightweight, flexible, and has good strength and fire resistance. Woven fiberglass fabric is commonly used in applications such as boat building, aerospace components, and insulation. 2. Non-woven fiberglass fabric: This type of fabric is made by bonding randomly oriented fiberglass fibers together. It is often used as a reinforcement material in composite structures, such as in the construction of wind turbine blades, automotive parts, and sports equipment. 3. Knitted fiberglass fabric: Knitted fiberglass fabric is made by interlocking loops of fiberglass yarns, creating a flexible and stretchable material. It is commonly used in applications where flexibility and conformability are required, such as in the manufacturing of thermal insulation blankets and protective clothing. 4. Chopped strand mat: Chopped strand mat is made by randomly aligning short strands of fiberglass and bonding them together with a binder. It is typically used as a reinforcement material in hand lay-up and spray-up processes for producing fiberglass molds, boat hulls, and automotive body panels. 5. Roving fabric: Roving fabric is made by arranging continuous strands of fiberglass parallel to each other and bonding them together. It is commonly used as a reinforcement material in filament winding and pultrusion processes for manufacturing pipes, tanks, and structural profiles. In addition to these types, there are also variations of fiberglass fabrics available, such as those with specialty coatings or treatments to enhance properties like water resistance or electrical conductivity. The specific type of fiberglass fabric used will depend on the desired application and performance requirements.

- Q: What are the different weight options for fiberglass fabric?

- The weight options for fiberglass fabric can vary depending on the specific application and manufacturer. However, common weight options for fiberglass fabric range from lightweight options such as 3 ounces per square yard (oz/yd²) to heavy-duty options weighing around 30 oz/yd² or more.

- Q: Can fiberglass fabric be used for insulation in tanks and vessels?

- Yes, fiberglass fabric can be used for insulation in tanks and vessels.

Send your message to us

Fiberglass Over Fabric Silica Glass Fiberglass Cloth with Vermiculite Coated

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords