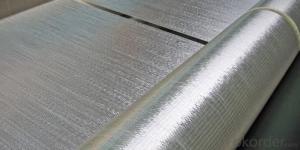

Fiberglass Mat Tissue Unidirectional Fabric 227gsm 1000mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Process

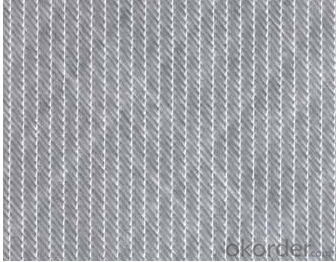

Fiberglass unidirectional fabric is the product combining the roving in certain angel of 0 ℃ or 90 ℃ with polyester yarn.

Properties

• Fiber straight arranged, fiber strength be ultimately used.

• No powder or emulsion, sink quickly, easy to operate.

• Easy to design, high strength in one direction.

Applications

Mainly be used as reinforced materials in the composite material industry.

• Matrix: unsaturated polyester resin, vinyl ester resin, epoxy resin and phenolic resin etc.

• Craft: winding, pultrusion, hand lay up, etc.

• Ultimate products: storage tank, tube, pultruded profiles, FRP body of boat, etc.

Specifications

specifications

Fibre type

0°Roving

90°Roving

Overall weight

Width

(g/㎡)

(g/㎡)

(g/㎡)

(mm)

EDW227

E-Glass

—

227

227

1524

EDW350

E-Glass

—

350

350

1524

EDW450

E-Glass

—

450

450

1524

EDJ600

E-Glass

480

120

600

1524

EDJ800

E-Glass

600

200

800

1524

EDJ1000

E-Glass

600

400

1000

1524

Packaging: Wrapped in PVC and placed within a cardboard carton.

FAQ of Woven roving combo mat:

Mainly be used as reinforced materials in the composite material industry.

• Matrix: unsaturated polyester resin, vinyl ester resin, epoxy resin and phenolic resin etc.

• Craft: pultrusion, RTM, hand lay up, etc.

• Ultimate products: pultruded profiles, FRP body of boat, insulation board, automobile body.

Delivery Detail: 15-21days

Other spec. can be custom made as per customer's request.

- Q: What are the different reinforcement orientations available for fiberglass mat tissue?

- The different reinforcement orientations available for fiberglass mat tissue include random chopped strand mat (CSM), continuous strand mat (CSM), woven roving, and unidirectional fiberglass.

- Q: Is fiberglass mat tissue suitable for automotive body panel repairs?

- Indeed, automotive body panel repairs can be successfully carried out using fiberglass mat tissue. This material, known for its robustness, endurance, and adaptability, is widely employed in automotive repairs. Its exceptional ability to conform to the distinctive curves of a vehicle makes it particularly effective in fixing body panels. Moreover, fiberglass mat tissue boasts resistance against corrosion, moisture, and chemicals, rendering it a prime selection for automotive purposes. Furthermore, its lightweight nature aids in reducing the overall weight of the vehicle, thereby enhancing fuel efficiency. All in all, fiberglass mat tissue proves to be a dependable and efficient choice for automotive body panel repairs.

- Q: Is fiberglass mat tissue suitable for insulation in hospitals?

- Yes, fiberglass mat tissue is suitable for insulation in hospitals. Fiberglass mat tissue is a lightweight and cost-effective material that offers excellent thermal insulation properties. It can effectively regulate temperature and reduce heat loss, making it an ideal choice for hospitals where maintaining a comfortable and controlled environment is crucial. Additionally, fiberglass mat tissue is non-combustible and resistant to mold, ensuring a safe and hygienic environment in hospitals. Its durability and ease of installation also make it a practical choice for insulation in healthcare facilities.

- Q: Is fiberglass mat tissue suitable for soundproofing?

- Fiberglass mat tissue can be suitable for soundproofing purposes, but its effectiveness may vary depending on the specific requirements and desired level of soundproofing. Fiberglass mat tissue is a lightweight and flexible material that can effectively absorb and dampen sound waves. It has good acoustic properties and can help reduce noise transmission, making it a viable option for soundproofing applications. However, it is important to note that fiberglass mat tissue alone may not provide sufficient soundproofing, especially in high-noise environments. For optimal results, it is recommended to combine it with other soundproofing materials such as acoustic foam panels or mass-loaded vinyl to enhance its soundproofing capabilities. Additionally, the thickness and density of the fiberglass mat tissue can also affect its sound absorption properties. Thicker and denser mats are generally more effective at attenuating sound waves, but they may also be less flexible and harder to install. In conclusion, while fiberglass mat tissue can contribute to soundproofing efforts, its suitability depends on the specific requirements, desired level of soundproofing, and the use of additional materials. Consulting with a soundproofing expert or conducting thorough research on the specific application is recommended to determine the most appropriate solution for effective soundproofing.

- Q: What are the different grades of fiberglass mat tissue available?

- There are several different grades of fiberglass mat tissue available in the market. These grades vary in terms of their weight, thickness, and strength. The most common grades include lightweight, medium-weight, and heavyweight fiberglass mat tissue. Lightweight fiberglass mat tissue is generally thinner and lighter in weight compared to other grades. It is often used for applications where flexibility and ease of handling are important. This grade is suitable for projects such as laminating lightweight structures, mold making, and repairs. Medium-weight fiberglass mat tissue is a versatile option that offers a balance between strength and flexibility. It is commonly used for various applications such as boat building, automotive repairs, and general fiberglass reinforcement. This grade provides adequate strength while still being manageable to work with. Heavyweight fiberglass mat tissue is the thickest and heaviest grade available. It offers superior strength and durability, making it ideal for applications that require high structural integrity. This grade is commonly used in industries such as construction, aerospace, and marine, where strength and toughness are crucial. Aside from these basic grades, there may be variations and special grades available depending on the manufacturer and specific requirements of a project. It is important to consult with a supplier or manufacturer to determine the most suitable grade of fiberglass mat tissue for a particular application.

- Q: Glass fiber cotton or ceramic fiber paper insulation?

- Glass fiber has low temperature resistance, preferably not higher than 550 degrees, and ceramic fiber has good temperature resistance.

- Q: Is fiberglass mat tissue resistant to UV radiation?

- Yes, fiberglass mat tissue is resistant to UV radiation. Fiberglass is known for its excellent resistance to UV rays, making it highly suitable for outdoor applications. UV radiation from the sun can cause materials to degrade, discolor, or become brittle over time. However, fiberglass mat tissue is made with a special resin that provides UV stability, allowing it to maintain its strength and integrity even when exposed to sunlight for extended periods. This makes fiberglass mat tissue a popular choice for various outdoor applications such as roofing, boat construction, and exterior cladding, where it is essential to have a material that can withstand the damaging effects of UV radiation.

- Q: How does the width and length of fiberglass mat tissue affect its application?

- The width and length of fiberglass mat tissue can affect its application by determining how easily it can be cut and maneuvered during installation. A wider and longer mat tissue may provide better coverage on larger surfaces, reducing the need for multiple pieces and potentially saving time and effort. Additionally, the length of the mat tissue can influence its strength and stability, as longer fibers may provide better reinforcement properties. Ultimately, the choice of width and length should be based on the specific requirements of the application, such as the size of the area to be covered or the desired level of reinforcement.

- Q: What is the maximum temperature that fiberglass mat tissue can withstand?

- The maximum temperature that fiberglass mat tissue can typically withstand is around 600-700 degrees Celsius.

- Q: How does the width of fiberglass mat tissue affect its conformability?

- The width of fiberglass mat tissue does not directly affect its conformability. Conformability is primarily determined by the flexibility and pliability of the material itself, rather than its width.

Send your message to us

Fiberglass Mat Tissue Unidirectional Fabric 227gsm 1000mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords