Fiberglass Mat Tissue - Glass Wool Insulation Blanket CNBM Best Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Glass Wool Insulation Blanket:

Glass Wool Blanket Continuous conveyors transport the mat to the COLD END of the plant for binder polymerization. The product is then cut to shape and packed for shipping. Also complete glass wool production lines employing latestgeneration technology to manufacture boards, rolled blankets and pipes for residential and industrial thermal and acoustic insulation needs, in compliance with the top international standards (EN, DIN, ASTM).

At the system HOT END, the raw materials are dosed, mixed, melted, fiberized, impregnated with a special binder and formed into a primitive mat of very fine fiber glass. Continuous conveyors transport the mat to the COLD END of the plant for binder polymerization. The product is then cut to shape and packed for shipping.

2.Main features of Glass Wool Blanket:

1.Light weight and easy to fabricate on job site

2.Excellent thermal, acoustical properties

3.Non-combustible and fire-retardant

4.Very economical, especially when using thick layers of insulation

5.Durable, life-time and termite proof

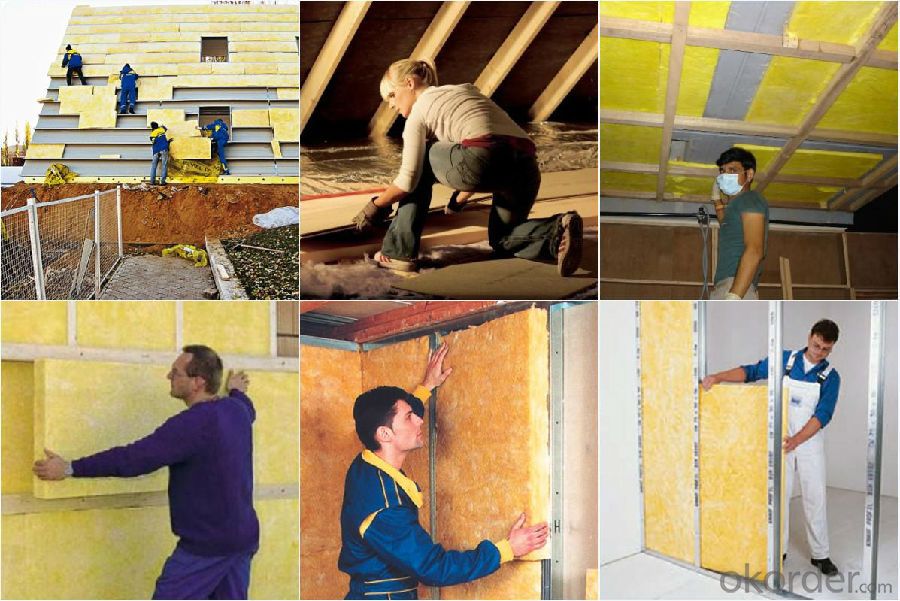

3.Glass Wool Blanket Images:

4. Glass Wool Insulation Blanket Technical Parameters:

Property | High/low temperature resistance, oil and fuel resistance, weathering resistance, O zone resistance etc. |

Shape | According to your requirement. |

Color | Any color is available ,according to your requirements. |

Material | NBR, CR, SBR, EPDM, IIR, NR, EP, Silicone, VITON etc. |

Hardness | 30-90ShoreA |

Delivery | In 10 days |

Packing | Plastic bag & carton box or according to your requirements. |

Application | Electronic field, industrial machine & equipment, house-hold appliance, telecommunication, automobile, medical equipment industry etc. |

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Glass Wool Blanket is one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Is fiberglass mat tissue suitable for wind energy applications?

- Yes, fiberglass mat tissue is suitable for wind energy applications. It is commonly used as a reinforcement material in wind turbine blades due to its high strength-to-weight ratio, excellent fatigue resistance, and ability to withstand harsh environmental conditions. The fiberglass mat tissue enhances the structural integrity and durability of the blades, enabling them to efficiently capture wind energy and sustain long-term operation.

- Q: Is fiberglass mat tissue suitable for underground applications?

- Yes, fiberglass mat tissue is suitable for underground applications. It is commonly used in underground construction projects due to its excellent strength, durability, and resistance to water and corrosion. Additionally, fiberglass mat tissue provides insulation and reinforcement, making it ideal for underground applications such as tunnels, basements, and pipelines.

- Q: How is fiberglass mat tissue used in the production of sports equipment?

- Fiberglass mat tissue is used in the production of sports equipment as it provides strength, flexibility, and durability to the final product. It is commonly used as a reinforcement material in the manufacturing of sports equipment such as snowboards, surfboards, hockey sticks, and tennis rackets. The fiberglass mat tissue is typically layered with resin and other materials, forming a composite structure that enhances the overall performance and longevity of the sports equipment.

- Q: Can fiberglass mat tissue be used for marine applications?

- Yes, fiberglass mat tissue can be used for marine applications. It is commonly used in boat building and repair due to its excellent strength, durability, and resistance to water and corrosion. The fiberglass mat tissue helps reinforce the structure of marine vessels and provides added protection against the harsh marine environment.

- Q: Does fiberglass mat tissue provide any thermal insulation?

- Indeed, thermal insulation is provided by fiberglass mat tissue. The reason lies in the fact that fiberglass possesses a low heat conductivity, impeding the effortless transfer of heat. As a mat tissue, it successfully captures air within its fibers, thereby generating an insulation layer. This layer serves as a shield against heat transfer via conduction and diminishes the loss of thermal energy. Consequently, fiberglass mat tissue proves to be a viable remedy for achieving thermal insulation in numerous sectors, including construction, automotive, and aerospace industries.

- Q: Is fiberglass mat tissue suitable for insulation in data centers?

- Fiberglass mat tissue can be suitable for insulation in data centers, depending on specific requirements and considerations. Fiberglass mat tissue is a type of fiberglass insulation that is commonly used for thermal and acoustic insulation purposes. It offers several advantages such as high thermal resistance, fire resistance, and sound absorption capabilities. In data centers, insulation plays a crucial role in maintaining a controlled and stable environment for the sensitive electronic equipment. Fiberglass mat tissue can help in reducing heat transfer, preventing the occurrence of hot spots, and maintaining the desired temperature levels within the data center. It can also contribute to noise reduction, which is important in reducing distractions and ensuring a comfortable working environment for the personnel. However, there are certain factors that need to be considered before determining the suitability of fiberglass mat tissue for insulation in data centers. Firstly, the specific requirements of the data center in terms of thermal insulation, fire resistance, and acoustic control should be thoroughly evaluated. Additionally, the installation process and maintenance requirements should be assessed to ensure that the insulation material can be effectively implemented and maintained in the data center's infrastructure. It is also important to consider alternative insulation options such as mineral wool, foam insulation, or other specialized materials that may better suit the unique demands of data centers. These materials might offer specific advantages like better fire resistance, moisture control, or higher thermal efficiency. Ultimately, the suitability of fiberglass mat tissue for insulation in data centers depends on a comprehensive evaluation of the specific needs, regulatory requirements, and available options. Consulting with experts in the field of data center construction and insulation can provide valuable insights and help in making an informed decision.

- Q: What is the moisture absorption rate of fiberglass mat tissue?

- The moisture absorption rate of fiberglass mat tissue can vary depending on various factors such as the specific type of fiberglass mat tissue and its manufacturing process. However, in general, fiberglass mat tissue is known to have a relatively low moisture absorption rate. This is due to the hydrophobic nature of fiberglass, which means it repels water and is not easily permeated by moisture. As a result, fiberglass mat tissue is often used in applications where moisture resistance is important, such as in roofing materials, insulation, and automotive parts. While the exact moisture absorption rate may not be readily available without specific product information, fiberglass mat tissue is generally considered to be a moisture-resistant material.

- Q: Can fiberglass mat tissue be used for making lightweight stairs?

- Yes, fiberglass mat tissue can be used for making lightweight stairs. Fiberglass mat tissue is a thin, lightweight material that is made from randomly oriented glass fibers bonded together with a resin. It is commonly used in construction and manufacturing industries due to its strength, durability, and lightweight properties. When used in the production of stairs, fiberglass mat tissue can be layered and molded to create a lightweight yet strong structure. This material has excellent tensile strength and dimensional stability, making it suitable for supporting the weight of individuals using the stairs. Furthermore, fiberglass mat tissue is resistant to moisture, chemicals, and UV rays, making it ideal for outdoor or high-moisture environments. It is also fire-resistant, which adds to the safety aspect of using it for stairs. Overall, fiberglass mat tissue is an excellent choice for making lightweight stairs as it combines strength, durability, and resistance to various environmental factors.

- Q: How does the fiber content of fiberglass mat tissue affect its strength?

- The strength of fiberglass mat tissue is directly influenced by its fiber content. As the fiber content increases, the strength of the tissue also increases. This is because the fibers provide the necessary structural integrity and reinforcement to the material. When the fiber content is raised, it results in a greater concentration of fibers, thereby boosting the overall strength of the tissue. Fiberglass mat tissue is comprised of randomly oriented glass fibers that are bound together with a resin binder. These fibers are responsible for carrying the load and resisting any external forces or stresses applied to the material. Consequently, the more fibers present in the tissue, the higher the load-carrying capacity and strength of the material. Moreover, a higher fiber content enhances the stiffness of the fiberglass mat tissue. Stiffness refers to the material's ability to resist deformation or bending under applied loads. With a larger quantity of fibers, the tissue becomes stiffer, making it less susceptible to bending or flexing. This increased stiffness contributes significantly to the overall strength of the material. It is important to note that while a higher fiber content improves the strength of fiberglass mat tissue, there is an optimal range where the benefits of additional fibers are maximized. Beyond this range, increasing the fiber content may not result in a substantial improvement in strength, and it may begin to have diminishing returns. Therefore, striking the right balance between fiber content and strength is crucial for specific applications. In conclusion, the strength of fiberglass mat tissue is directly affected by its fiber content. Increasing the fiber content leads to a higher concentration of fibers, thereby enhancing the material's load-carrying capacity and stiffness. Finding the optimal fiber content is essential for maximizing the strength of the tissue in specific applications.

- Q: Can fiberglass mat tissue be used for making boat hulls?

- Yes, fiberglass mat tissue can be used for making boat hulls. It is commonly used in boat manufacturing due to its strength, durability, and ability to provide structural reinforcement.

Send your message to us

Fiberglass Mat Tissue - Glass Wool Insulation Blanket CNBM Best Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords