Fiberglass Mat Tissue Glass Wool Insulation Blanket CNBM Best Quality Best 1

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Glass Wool Insulation Blanket:

Glass Wool Blanket Continuous conveyors transport the mat to the COLD END of the plant for binder polymerization. The product is then cut to shape and packed for shipping. Also complete glass wool production lines employing latestgeneration technology to manufacture boards, rolled blankets and pipes for residential and industrial thermal and acoustic insulation needs, in compliance with the top international standards (EN, DIN, ASTM).

At the system HOT END, the raw materials are dosed, mixed, melted, fiberized, impregnated with a special binder and formed into a primitive mat of very fine fiber glass. Continuous conveyors transport the mat to the COLD END of the plant for binder polymerization. The product is then cut to shape and packed for shipping.

2.Main features of Glass Wool Blanket:

1.Light weight and easy to fabricate on job site

2.Excellent thermal, acoustical properties

3.Non-combustible and fire-retardant

4.Very economical, especially when using thick layers of insulation

5.Durable, life-time and termite proof

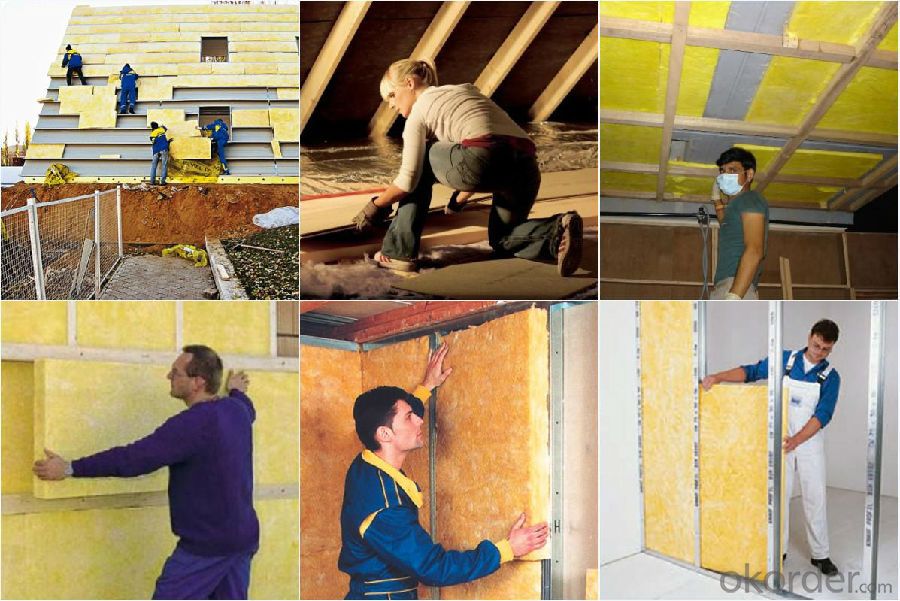

3.Glass Wool Blanket Images:

4. Glass Wool Insulation Blanket Technical Parameters:

Property | High/low temperature resistance, oil and fuel resistance, weathering resistance, O zone resistance etc. |

Shape | According to your requirement. |

Color | Any color is available ,according to your requirements. |

Material | NBR, CR, SBR, EPDM, IIR, NR, EP, Silicone, VITON etc. |

Hardness | 30-90ShoreA |

Delivery | In 10 days |

Packing | Plastic bag & carton box or according to your requirements. |

Application | Electronic field, industrial machine & equipment, house-hold appliance, telecommunication, automobile, medical equipment industry etc. |

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Glass Wool Blanket is one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Can fiberglass mat tissue be used for creating molds?

- No, fiberglass mat tissue cannot be used for creating molds. Fiberglass mat tissue is a thin, lightweight material that is typically used as a reinforcement layer in fiberglass composite applications. It is not designed to be a mold-making material. Instead, materials such as silicone, resin, or plaster are commonly used to create molds due to their ability to capture fine details and provide a smooth surface finish.

- Q: What is the dimensional stability of fiberglass mat tissue?

- The ability of fiberglass mat tissue to maintain its size and shape under different conditions is referred to as its dimensional stability. Fiberglass mat tissue is well-known for its outstanding dimensional stability, which makes it highly resistant to shrinking, expanding, or warping. This stability is achieved through the manufacturing process, where glass fibers are bonded together using a binder material. Not only does this binder ensure the integrity of the mat tissue, but it also helps it maintain its dimensional stability over time. Moreover, the exceptional dimensional stability of fiberglass mat tissue is further enhanced by its inherent properties, such as its high strength and stiffness. These characteristics have made fiberglass mat tissue a popular choice in various industries, including construction, automotive, and aerospace, where maintaining consistent dimensions is essential for optimal performance and durability.

- Q: How does fiberglass mat tissue perform in terms of chemical resistance?

- Fiberglass mat tissue generally exhibits excellent chemical resistance properties. The material is typically made from glass fibers that are held together by a binder, and this composition allows for resistance to a wide range of chemicals. Fiberglass mat tissue is commonly used as a reinforcement in composite materials, such as fiberglass-reinforced plastics (FRP), due to its ability to withstand exposure to various chemicals without degrading or deteriorating. The chemical resistance of fiberglass mat tissue can vary depending on the specific type and quality of the material, as well as the specific chemical being encountered. However, in general, it is highly resistant to most acids, alkalis, solvents, and other corrosive substances. This resistance makes it a suitable choice for applications where the material may come into contact with aggressive chemicals, such as in chemical processing plants, water treatment facilities, or storage tanks. It is important to note that while fiberglass mat tissue is generally chemically resistant, it may not be completely impervious to all chemicals. Some highly concentrated or specialized chemicals may still have the potential to cause damage or deterioration over time. Therefore, it is always advisable to consult the manufacturer's specifications and recommendations for specific chemical resistance information before using fiberglass mat tissue in a particular application. Overall, fiberglass mat tissue is known for its strong chemical resistance properties, making it a reliable choice for applications where exposure to chemicals is expected.

- Q: Is fiberglass mat tissue resistant to moisture?

- Yes, fiberglass mat tissue is resistant to moisture.

- Q: Does fiberglass mat tissue require any special treatment for UV resistance?

- Yes, fiberglass mat tissue does require special treatment for UV resistance. Fiberglass mat tissue is typically made up of fine strands of glass fibers, which can be susceptible to damage from prolonged exposure to ultraviolet (UV) radiation. UV rays can cause the fibers to degrade, leading to a loss in strength and dimensional stability. To enhance the UV resistance of fiberglass mat tissue, manufacturers often apply a special coating or treatment to the material. This treatment helps to protect the fibers from UV radiation and prevent their degradation. The specific treatment used can vary depending on the intended application and the desired level of UV resistance. Additionally, it is important to note that even with special treatment, fiberglass mat tissue may still be subject to some level of UV damage over time. Therefore, it is recommended to minimize prolonged exposure to direct sunlight whenever possible to ensure the longevity and performance of the material.

- Q: What is the density of fiberglass mat tissue?

- The density of fiberglass mat tissue may differ depending on its specific type and manufacturer. On average, it has a density of approximately 1.5 g/cm³ or 1500 kg/m³. It should be emphasized that the density might slightly vary depending on the thickness and composition of the fiberglass mat tissue.

- Q: Is fiberglass mat tissue compatible with different adhesives?

- Yes, fiberglass mat tissue is compatible with different adhesives. Fiberglass mat tissue is a versatile material that can be used in various applications such as construction, automotive, and aerospace industries. It is commonly used as a reinforcement material in composites, where it is combined with resin and adhesive to create strong and durable structures. The compatibility of fiberglass mat tissue with different adhesives depends on several factors such as the type of adhesive, the specific application, and the desired performance requirements. Fiberglass mat tissue can be compatible with a wide range of adhesives including epoxy, polyester, vinyl ester, and polyurethane adhesives. It is important to consider the specific properties and characteristics of the adhesive and the fiberglass mat tissue when selecting the adhesive for a particular application. Factors such as curing time, viscosity, bond strength, and chemical resistance should be taken into account to ensure optimal adhesion and performance. In some cases, surface treatment or priming may be necessary to enhance the compatibility between the fiberglass mat tissue and the adhesive. This can involve applying a primer or using a specific surface treatment method to promote adhesion and ensure a strong bond between the two materials. Overall, fiberglass mat tissue is compatible with different adhesives, but it is crucial to consider the specific requirements of the application and select the appropriate adhesive and surface treatment method to achieve the desired results.

- Q: Can fiberglass mat tissue be used for insulating crawl spaces?

- Yes, fiberglass mat tissue can be used for insulating crawl spaces. It is a commonly used material for thermal insulation due to its good insulation properties and moisture resistance. It can help to reduce heat loss and prevent moisture buildup in crawl spaces, making it an effective choice for insulating this area.

- Q: Glass fiber cotton or ceramic fiber paper insulation?

- Glass fiber cotton bar, there are more air inside, the effect may be better

- Q: Does fiberglass mat tissue require any surface preparation before application?

- Yes, fiberglass mat tissue typically requires some surface preparation before application. This is to ensure proper adhesion and bonding between the fiberglass mat tissue and the surface it is being applied to. The exact surface preparation required may vary depending on the specific application and the condition of the surface. However, some common steps in surface preparation for fiberglass mat tissue include cleaning the surface to remove any dirt, grease, or other contaminants, sanding or roughening the surface to create a better bonding surface, and applying a primer or other bonding agent if necessary. It is important to carefully follow the manufacturer's instructions and recommendations for surface preparation to ensure the best results and optimal performance of the fiberglass mat tissue.

Send your message to us

Fiberglass Mat Tissue Glass Wool Insulation Blanket CNBM Best Quality Best 1

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords