Fiberglass Mat Tissue for Boat Production Glass Fiber Woven Roving

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

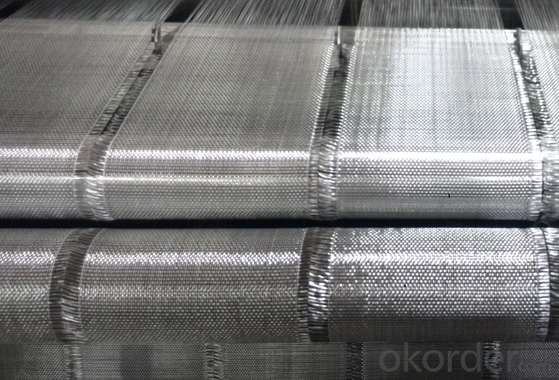

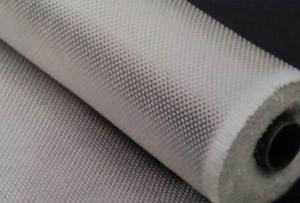

Structure of woven roving Description

1.Glass Woven Roving are bidirectional fabric made by direct roving in plain weave pattern . 2.High quality roving 3.Skilled workers to operate, to ensure the quality of fabric 4. Any width we can operate 5.Perfact packing 6.including the EWR200.EWR400,EWR570....cwr135,cwr180.cwr200.cwr500..... 7.The details as per customer requriments

Main Features of the woven roving

1. Low Fuzz,dirt,impurity and other stains.......

2. Fast wet-out.

3. Even thickness

4.Good covering

Woven roving Images:

Woven roving Specification:

Normal type | EWR800-1000 | Test Standard |

Apperance | Good | GB/T 18370-2001 |

Density(warpxweft)(end/cm) | 1.8 X 1.5 | GB/T 7689.2-2001 |

Tex (warpxweft) | 2400x2400 | ISO1889 |

Moisture content(%) | ≤0.10 | ISO3344 |

Loss on ignition(%) | 0.40-0.80 | ISO1887 |

Glass | E-glass | N/A |

FAQ of woven roving:

Woven Roving is a high –performance reinforcement widely used in hand lay-up and machanical production

1) Good moldability & drapability

2) High strength

3) Excellent rollout characteristics

4) Fast wet -out

- Q: Is fiberglass mat tissue fire-resistant?

- Fiberglass mat tissue is not naturally fire-resistant, contrary to popular belief. Although fiberglass itself is non-combustible, manufacturers usually mix the mat tissue with a flammable binder or resin. Nevertheless, there are specialized fiberglass mat tissue options that have undergone treatment with fire-resistant coatings or additives. These treated materials offer enhanced fire resistance properties and are frequently utilized in construction and insulation materials that prioritize fire safety. It is crucial to carefully examine the product specifications or seek advice from the manufacturer to ascertain the fire resistance capabilities of a specific fiberglass mat tissue.

- Q: How does fiberglass mat tissue perform in high temperatures?

- Due to its inherent heat resistance properties, fiberglass mat tissue is highly effective in high temperatures. The mat is crafted from woven glass fibers, creating a durable and sturdy material. These glass fibers possess a high melting point, enabling the fiberglass mat tissue to endure elevated temperatures without distorting or compromising its structural integrity. Unlike other materials, fiberglass mat tissue does not shrink, warp, or become brittle when exposed to high temperatures. It maintains its dimensional stability and mechanical strength, making it suitable for a wide range of applications in industries such as automotive, aerospace, construction, and insulation. Furthermore, fiberglass mat tissue acts as a thermal insulator, providing protection against heat transfer. It effectively resists heat conduction and radiation, assisting in maintaining the desired temperature in a given environment or preventing heat damage to nearby components. Moreover, fiberglass mat tissue is non-combustible, meaning it does not burn or release toxic gases when subjected to fire. This characteristic makes it a dependable choice for applications that necessitate fire resistance, such as fireproofing insulation or protective barriers. In conclusion, fiberglass mat tissue excels in high temperatures. Its heat resistance, dimensional stability, mechanical strength, thermal insulation properties, and non-combustible nature establish it as an outstanding material for demanding environments where elevated temperatures are present.

- Q: How thick is fiberglass mat tissue typically?

- Fiberglass mat tissue, which is sometimes referred to as fiberglass mat or simply mat, is available in different thicknesses depending on its intended purpose. It can be as thin as 0.5 millimeters (mm) or as thick as 3 mm. However, the thicknesses most commonly used for fiberglass mat tissue are 1.5 mm and 2 mm. These thicknesses are well-suited for reinforcing laminates, composite materials, and creating surface finishes. It should be noted that the actual thickness of fiberglass mat tissue may vary depending on the manufacturer and the specific project requirements.

- Q: Can fiberglass mat tissue be used for HVAC insulation?

- Generally, fiberglass mat tissue is not utilized for HVAC insulation. The insulation used in HVAC systems typically necessitates materials that are purposely engineered to possess significant thermal resistance and inhibit the transmission of heat or cold air. Fiberglass mat tissue is frequently employed as a reinforcing material in the construction of composite materials, such as fiberglass panels or structures, rather than for insulation purposes. Insulation materials intended for HVAC systems are commonly composed of materials such as fiberglass insulation boards, foam insulation, or mineral wool, which possess superior thermal resistance properties and are specifically tailored for HVAC applications.

- Q: What is the moisture vapor transmission rate of fiberglass mat tissue?

- The moisture vapor transmission rate of fiberglass mat tissue can vary depending on its specific composition and manufacturing process. It is typically low, as fiberglass is known for its moisture resistance properties.

- Q: What is the expected lifespan of fiberglass mat tissue in chemical storage applications?

- The lifespan of fiberglass mat tissue in chemical storage applications can vary depending on several factors. These factors include the type and concentration of chemicals being stored, as well as the specific conditions of the storage environment. Fiberglass mat tissue is widely used in chemical storage applications because it has excellent corrosion resistance and provides structural reinforcement. However, it is important to note that fiberglass mat tissue is not completely immune to chemical degradation. In general, fiberglass mat tissue can withstand a wide range of chemicals and has a relatively long lifespan when properly maintained. It is typically designed to last for several years, and some manufacturers offer warranties ranging from 10 to 20 years. However, aggressive chemicals or extreme storage conditions can accelerate the degradation of fiberglass mat tissue. Chemicals with high acidity or alkalinity, extreme temperatures, or prolonged exposure to UV radiation can potentially reduce the lifespan of the material. To ensure the maximum lifespan of fiberglass mat tissue in chemical storage applications, it is crucial to carefully select the appropriate type of fiberglass mat tissue that is specifically designed for the intended chemicals and storage conditions. Regular inspections, maintenance, and proper handling of the chemicals can also help prolong the lifespan of the material. Ultimately, it is advisable to consult with the manufacturer or a qualified engineer to determine the expected lifespan of fiberglass mat tissue in a specific chemical storage application. They can provide more accurate information based on the specific circumstances.

- Q: Can fiberglass mat tissue be used for repairing damaged fiberglass structures?

- Fiberglass mat tissue is a valuable tool in the repair of damaged fiberglass structures. This versatile material is frequently utilized in both the construction and repair of fiberglass structures. Its thin, flexible nature allows it to be easily shaped and molded to fit any damaged area. Furthermore, its reputation for strength and durability makes it an optimal choice for reinforcing and fortifying weakened fiberglass structures. Boats, car bodies, and other fiberglass products commonly benefit from the application of fiberglass mat tissue in the repair of cracks, holes, and other damages. Moreover, the simple bond between the damaged area and the fiberglass mat tissue can be easily achieved through the use of epoxy or polyester resin, resulting in a robust and long-lasting repair. All in all, fiberglass mat tissue is a dependable and efficient solution for the repair of damaged fiberglass structures.

- Q: How does the fiber content of fiberglass mat tissue affect its strength?

- The strength of fiberglass mat tissue is directly influenced by its fiber content. As the fiber content increases, the strength of the tissue also increases. This is because the fibers provide the necessary structural integrity and reinforcement to the material. When the fiber content is raised, it results in a greater concentration of fibers, thereby boosting the overall strength of the tissue. Fiberglass mat tissue is comprised of randomly oriented glass fibers that are bound together with a resin binder. These fibers are responsible for carrying the load and resisting any external forces or stresses applied to the material. Consequently, the more fibers present in the tissue, the higher the load-carrying capacity and strength of the material. Moreover, a higher fiber content enhances the stiffness of the fiberglass mat tissue. Stiffness refers to the material's ability to resist deformation or bending under applied loads. With a larger quantity of fibers, the tissue becomes stiffer, making it less susceptible to bending or flexing. This increased stiffness contributes significantly to the overall strength of the material. It is important to note that while a higher fiber content improves the strength of fiberglass mat tissue, there is an optimal range where the benefits of additional fibers are maximized. Beyond this range, increasing the fiber content may not result in a substantial improvement in strength, and it may begin to have diminishing returns. Therefore, striking the right balance between fiber content and strength is crucial for specific applications. In conclusion, the strength of fiberglass mat tissue is directly affected by its fiber content. Increasing the fiber content leads to a higher concentration of fibers, thereby enhancing the material's load-carrying capacity and stiffness. Finding the optimal fiber content is essential for maximizing the strength of the tissue in specific applications.

- Q: Can fiberglass mat tissue be used in corrosive environments?

- The resistance of fiberglass mat tissue to corrosion relies on its specific composition and quality. It can be used to some extent in corrosive environments. Fiberglass mat tissue is manufactured by combining fiberglass strands with a binder material. Although fiberglass itself is generally resistant to corrosion, the binder material used in the mat tissue can vary and impact its resistance to corrosive environments. Certain binders may offer better protection against corrosion, while others may be more prone to degradation. To enhance the corrosion resistance of fiberglass mat tissue in corrosive environments, it is possible to apply additional protective coatings or treatments. These coatings create a barrier against corrosive elements and prolong the material's lifespan. To determine the suitability of fiberglass mat tissue for a specific application, it is crucial to consider the particular corrosive environment and seek advice from experts or manufacturers. They can provide guidance on the ideal composition, treatment, and necessary precautions to ensure optimal performance and durability in corrosive environments.

- Q: Can fiberglass mat tissue be painted over?

- Yes, fiberglass mat tissue can be painted over. However, there are a few considerations that need to be taken into account. First, it is important to ensure that the fiberglass mat tissue is clean and free from any dirt, grease, or other contaminants before painting. This can be achieved by cleaning the surface with a mild detergent and water, followed by thorough rinsing and drying. Secondly, it is recommended to apply a primer before painting to improve adhesion and promote a smoother finish. A high-quality primer specifically designed for use on fiberglass surfaces should be used, following the manufacturer's instructions for application. Finally, when choosing the paint, it is crucial to select one that is compatible with fiberglass materials. Acrylic or epoxy-based paints are often recommended as they provide good adhesion and durability on fiberglass surfaces. By following these steps and using appropriate materials, it is possible to paint over fiberglass mat tissue successfully. However, it is always advisable to consult with a professional or follow the manufacturer's recommendations for optimal results.

Send your message to us

Fiberglass Mat Tissue for Boat Production Glass Fiber Woven Roving

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords