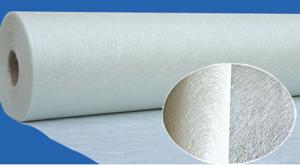

Fiberglass Mat Tissue - Fiberglass Woven Roving Compressed Mat 800g 200~2600mm

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description & application | |||||||||||||||||||||||||||||||||||||||

◎ This mat is a combination of woven roving and chopped glass fiber. The layer of chopped strand is stitched together with woven roving by polyester thread. It is mainly applied in the processes of molding compressing, pultrusion, RTM, filament winding etc.. | |||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||

◎ Increase strength, reduce product weight and better surface finish. | |||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||

Each roll is wrapped by PE film and then packed into carton. Stacking in bulk or palletized is available; the pallet shall be no higher than 2 layers. | |||||||||||||||||||||||||||||||||||||||

- Q: How does the roll diameter of fiberglass mat tissue affect its handling?

- The handling of fiberglass mat tissue can be significantly impacted by the diameter of the roll. When the roll diameter is larger, the roll becomes heavier and bulkier, which poses a greater challenge for handling and maneuvering. This is especially important when the fiberglass mat tissue needs to be transported or installed manually. Furthermore, lifting and moving a larger roll diameter requires more physical effort, putting strain on those handling it. Additionally, larger roll diameters occupy more space, making storage and transportation more complicated. On the other hand, a smaller roll diameter makes the fiberglass mat tissue easier to handle due to its lighter and more compact nature. This is particularly advantageous in situations that involve frequent movement and installation, such as construction sites or manufacturing facilities. Moreover, a smaller roll diameter allows for more efficient storage and transportation as it takes up less space and can be easily stacked. This optimization of logistics helps minimize the costs associated with storage and transportation. In summary, the roll diameter of fiberglass mat tissue directly impacts its handling characteristics. Larger diameters make handling more challenging, while smaller diameters provide easier handling and improved storage efficiency.

- Q: Can fiberglass mat tissue be used for wind turbine nacelles?

- Yes, fiberglass mat tissue can be used for wind turbine nacelles. Fiberglass mat tissue is a lightweight and durable material that is commonly used in various industries, including wind energy. It is highly suitable for wind turbine nacelles due to its excellent mechanical properties, such as high strength, stiffness, and resistance to corrosion and fatigue. Additionally, fiberglass mat tissue can be easily molded into complex shapes, making it ideal for fabricating the intricate components of wind turbine nacelles. Overall, using fiberglass mat tissue in wind turbine nacelles helps to enhance their structural integrity, reduce weight, and improve the overall performance and longevity of the turbines.

- Q: How thick is fiberglass mat tissue typically?

- Fiberglass mat tissue, which is sometimes referred to as fiberglass mat or simply mat, is available in different thicknesses depending on its intended purpose. It can be as thin as 0.5 millimeters (mm) or as thick as 3 mm. However, the thicknesses most commonly used for fiberglass mat tissue are 1.5 mm and 2 mm. These thicknesses are well-suited for reinforcing laminates, composite materials, and creating surface finishes. It should be noted that the actual thickness of fiberglass mat tissue may vary depending on the manufacturer and the specific project requirements.

- Q: How is fiberglass mat tissue used in the production of sports equipment?

- Fiberglass mat tissue is used in the production of sports equipment as it provides strength, flexibility, and durability to the final product. It is commonly used as a reinforcement material in the manufacturing of sports equipment such as snowboards, surfboards, hockey sticks, and tennis rackets. The fiberglass mat tissue is typically layered with resin and other materials, forming a composite structure that enhances the overall performance and longevity of the sports equipment.

- Q: Can fiberglass mat tissue be used for repairing fiberglass boats?

- Yes, fiberglass mat tissue can be used for repairing fiberglass boats. Fiberglass mat tissue is a versatile material that is commonly used in repairing and reinforcing fiberglass structures, including boats. It is designed to provide strength and durability, making it an ideal choice for patching holes, cracks, or damaged areas in fiberglass boat hulls. The mat tissue is typically layered with resin to form a solid and stable repair, ensuring that the boat remains structurally sound. Additionally, fiberglass mat tissue is easy to work with and can be cut to the desired size and shape, making it suitable for various repair applications on fiberglass boats.

- Q: How does the surface finish of fiberglass mat tissue affect its adhesion to resin?

- The surface finish of fiberglass mat tissue can significantly affect its adhesion to resin. The surface finish refers to the texture or smoothness of the fiberglass mat tissue. In general, a rougher surface finish tends to provide better adhesion to resin. This is because a rough surface provides more surface area for the resin to adhere to, allowing for a stronger bond. Rougher surface finishes can be achieved through various manufacturing techniques, such as using coarser fibers or adding texturizing agents during production. On the other hand, a smoother surface finish may result in weaker adhesion. A smooth surface does not provide as much surface area for the resin to bond with, leading to a weaker and less durable bond. Smoother surface finishes can be achieved by using finer fibers or through additional processing steps to smooth out the surface. It is important to consider the specific application and requirements when choosing the surface finish of fiberglass mat tissue. For applications that require high strength and durability, a rougher surface finish may be preferred to ensure optimal adhesion to the resin. Conversely, for applications where a weaker bond is acceptable or where a smoother surface finish is desired for aesthetic reasons, a smoother surface finish may be chosen. Ultimately, the surface finish of fiberglass mat tissue plays a critical role in determining the adhesion to resin. It is essential to select the appropriate surface finish to achieve the desired strength, durability, and performance in various applications.

- Q: Can fiberglass mat tissue be used for repairing damaged fiberglass structures?

- Yes, fiberglass mat tissue can be used for repairing damaged fiberglass structures. The mat tissue is designed to provide strength and reinforcement to the damaged area, making it an effective solution for repairing fiberglass structures.

- Q: What are the different manufacturing processes for fiberglass mat tissue?

- Various manufacturing processes exist for fiberglass mat tissue, each aiming to create a distinct mat type with unique characteristics. One prevalent method is the wet-laid process. Initially, glass fibers are chopped into small fragments and dispersed in a water-based slurry. This slurry is then spread onto a moving screen or belt, allowing the water to drain off and generating a mat composed of randomly oriented fibers. Subsequently, the mat is dried and further treated to achieve the desired thickness and density. Another technique is the dry-laid process. Here, glass fibers are first transformed into a loose, fluffy mat using either air or mechanical means. Subsequently, the loose fibers are bound together using a binder material, such as resin or latex, which is sprayed onto the fibers. The binder solidifies, resulting in a cohesive mat with controlled thickness and density. A third process is the stitch-bonded process. In this procedure, individual glass fibers are mechanically stitched together using a series of needles. These needles pierce the fibers and interlock them, producing a bonded fabric. This approach enables the production of mats with high strength and dimensional stability. Lastly, the spunbond process involves extruding molten glass through fine spinnerets to create continuous filaments. These filaments are then accumulated onto a moving belt or screen, where they are bonded together using either heat or a binder. This method generates mats with uniform fiber distribution and high strength. In summary, the selection of a manufacturing process for fiberglass mat tissue depends on the desired properties of the final product, including strength, thickness, density, and dimensional stability. Each process possesses its own advantages and disadvantages, and manufacturers will choose the most suitable method based on their specific requirements.

- Q: Can fiberglass mat tissue be used for repairing fiberglass canoes?

- Yes, fiberglass mat tissue can be used for repairing fiberglass canoes. It is commonly used to reinforce and strengthen the damaged areas of the canoe by providing additional structural support.

- Q: Is fiberglass mat tissue compatible with different types of resins?

- Yes, fiberglass mat tissue is compatible with different types of resins. It is commonly used in the construction industry as a reinforcement material for various resin systems, including polyester, epoxy, and vinyl ester resins. The compatibility of fiberglass mat tissue with different resins makes it versatile and suitable for a wide range of applications.

Send your message to us

Fiberglass Mat Tissue - Fiberglass Woven Roving Compressed Mat 800g 200~2600mm

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords