Fiberglass Mat Tissue - E-Glass Fiberglass Woven Roving, 400g, 1600mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 300000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

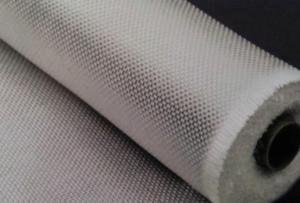

Structure of woven roving Description

1,high strenth,corosion and resistence

2,consistent thickness,no fuzz

3,rapid impregnating

Glass woven rovings are bidirectional fabric by direct rovings in plain weave pattern. They are applicable for hand lay-up, winding and compress molding process, suitable for manufacturing tank, boat, automobile parts and other FRP products.

Main Features of the woven roving

1)Drapes well to suit the surface of intricate moulds

2)Fast wet-through and wet out

3)Easy handing and better appearance of the composite parts

4)Compatible with Unsaturated polyester resin

5)Very high laminate strength properties

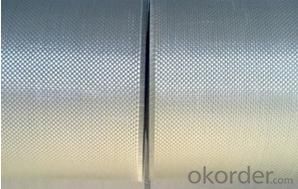

Woven roving Images

Woven roving Specification: weight& thickness

Normal type | EWR800-1000 | Test Standard |

Apperance | Good | GB/T 18370-2001 |

Density(warpxweft)(end/cm) | 1.8 X 1.5 | GB/T 7689.2-2001 |

Tex (warpxweft) | 2400x2400 | ISO1889 |

Moisture content(%) | ≤0.10 | ISO3344 |

Loss on ignition(%) | 0.40-0.80 | ISO1887 |

Glass | E-glass | N/A |

FAQ of woven roving:

Delivery Detail: 15-21days

Other spec. can be custom made as per customer's request.

- Q: Can fiberglass mat tissue be used for flooring insulation?

- No, fiberglass mat tissue is not typically used for flooring insulation. Fiberglass mat tissue is a lightweight material often used in the construction industry for applications such as reinforcing plaster and concrete, as well as for insulation in walls and ceilings. However, when it comes to flooring insulation, other materials such as foam boards or batt insulation are more commonly used. These materials provide better thermal and sound insulation properties specifically designed for flooring applications. Additionally, foam boards and batt insulation are easier to install and are better suited to withstand the pressures and demands of foot traffic on the flooring.

- Q: Are there any health risks associated with fiberglass mat tissue?

- Fiberglass mat tissue poses potential health risks indeed. Its composition consists of minuscule glass fibers that can be released into the air when the material is cut, sanded, or disturbed. Inhaling these fibers can lead to skin, eye, and respiratory irritation. Immediate exposure may cause coughing, wheezing, and breathing difficulties. Prolonged exposure to fiberglass fibers has been associated with severe health complications, including lung damage and an elevated likelihood of developing respiratory conditions like asthma or bronchitis. To mitigate exposure and potential health issues, it is crucial to adhere to proper precautions, such as wearing protective clothing, goggles, and a mask when handling fiberglass mat tissue.

- Q: Is fiberglass mat tissue suitable for aerospace interiors?

- Fiberglass mat tissue is indeed a suitable material for aerospace interiors. This material is both lightweight and extremely versatile, providing exceptional strength and durability. Its widespread use in aerospace applications is due to its ability to meet rigorous fire safety standards, including low smoke and toxicity emissions. Furthermore, fiberglass mat tissue exhibits resistance to moisture, chemicals, and temperature fluctuations, making it an ideal option for the challenging conditions found within an aircraft cabin. Its exceptional sound insulation properties further contribute to its suitability for aerospace interiors, guaranteeing a pleasant and noise-free environment for passengers. All in all, fiberglass mat tissue offers a dependable and effective solution for aerospace interior applications.

- Q: Does fiberglass mat tissue require any special surface bonding agents?

- Special surface bonding agents are necessary for fiberglass mat tissue. It is commonly used as a reinforcement material in industries like construction, automotive, and aerospace. To achieve a strong bond between the fiberglass mat tissue and the substrate, a suitable bonding agent or adhesive is needed. The bonding agent plays a crucial role in creating a durable and robust bond between the fiberglass mat tissue and the applied surface. It enhances the overall strength, integrity, and performance of the composite material. Additionally, it prevents delamination or separation of the fiberglass mat tissue from the substrate. The type of bonding agent required may vary depending on the specific application and the substrate's properties. Typically, epoxy-based bonding agents are widely used for bonding fiberglass mat tissue due to their excellent bonding strength, chemical resistance, and durability. Before applying the bonding agent, it is essential to thoroughly clean the surface and remove any contaminants that may affect adhesion. The bonding agent can then be applied using appropriate techniques such as brushing, spraying, or rolling. In conclusion, special surface bonding agents are necessary for fiberglass mat tissue to ensure proper adhesion and enhance the performance of the composite material. The choice of bonding agent depends on the specific application and substrate properties. Adequate surface preparation is also crucial for achieving a strong and durable bond.

- Q: Can fiberglass mat tissue be used for insulation in cold environments?

- Yes, fiberglass mat tissue can be used for insulation in cold environments. It has excellent thermal insulation properties and is commonly used in construction to provide insulation against cold temperatures.

- Q: How is fiberglass mat tissue used in the production of shower enclosures?

- Fiberglass mat tissue is used in the production of shower enclosures to reinforce the structure and provide added strength. It is typically applied as a layer between the gel coat and the fiberglass resin, creating a durable and rigid surface that can withstand daily use and potential impacts. The fiberglass mat tissue helps prevent cracking and warping, ensuring the shower enclosure maintains its shape and integrity over time.

- Q: Can fiberglass mat tissue be used for insulation in cold climates?

- Insulation in cold climates can be achieved using fiberglass mat tissue. This material is renowned for its exceptional thermal insulation qualities, making it a favored choice for insulating structures in colder regions. By design, fiberglass mat tissue traps air pockets within its structure, effectively preventing heat transfer and maintaining warmth inside the building. This solution is not only cost-effective but also efficient in insulating walls, roofs, and floors in cold climates, resulting in reduced energy consumption for heating. Moreover, fiberglass possesses moisture resistance and retains its insulation properties even in extremely low temperatures. In summary, fiberglass mat tissue is a suitable option for insulation in cold climates due to its thermal insulation capabilities, durability, and resistance to moisture.

- Q: How does the surface finish of fiberglass mat tissue affect its adhesion to resin?

- The surface finish of fiberglass mat tissue plays a crucial role in its adhesion to resin. A smooth surface finish allows for better contact and bonding between the tissue and resin, resulting in stronger adhesion. On the other hand, a rough or textured surface finish may hinder the contact area and reduce the bond strength between the tissue and resin. Therefore, a smooth surface finish is generally preferred for achieving optimal adhesion between fiberglass mat tissue and resin.

- Q: Is fiberglass mat tissue recyclable?

- Yes, fiberglass mat tissue is recyclable.

- Q: Can fiberglass mat tissue be recycled?

- Indeed, recycling is a viable option for fiberglass mat tissue. Fiberglass, composed of glass fibers and resin, allows for reusing both elements. To recycle, the glass fibers and resin are separated, typically via mechanical grinding or melting techniques. The isolated fibers are subsequently employed in the production of fresh fiberglass products like insulation, roofing materials, or even new fiberglass mat tissue. The recycling of fiberglass plays a critical role in lessening the environmental impact of this material by diverting it from landfills and conserving valuable resources. It's important to acknowledge, however, that the recycling process can be intricate and costly, which means not all recycling facilities may accept fiberglass mat tissue.

Send your message to us

Fiberglass Mat Tissue - E-Glass Fiberglass Woven Roving, 400g, 1600mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 300000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords