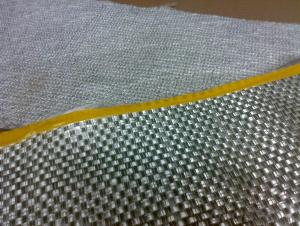

Fiberglass Mat Tissue - E Glass Fiber Woven Roving (200gsm-800gsm)

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 16000 kg

- Supply Capability:

- 160000Kg Per Month kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Introductions

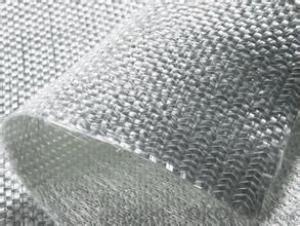

E-Glass Woven Rovings are bidirectional fabric made by interweaving direct rovings.

E-Glass Woven Rovings are compatible with unsaturated polyester, vinyl ester, epoxy and phenolic resins.

E-Glass Woven Rovings are a high-performance reinforcement widely used in hand lay up and robot processes to manufacture boats, vessels, plane and automotive parts, furniture and sports facilities.

2.Product Features

Warp and weft rovings aligned in a parallel and flat manner, resulting in uniform tension

Densely aligned fibers, resulting in high dimensional stability and making handling easy

Good moldability, fast and complete wet out in resins, resulting in high productivity

Good mechanical properties and high strength of parts

3.Product Specifications

Property | Area Weight | Moisture Content | Size Content | Width |

(%) | (%) | (%) | (mm) | |

Test Method | IS03374 | ISO3344 | ISO1887 | |

EWR200 | ±7.5 | ≤0.15 | 0.4-0.8 | 20-3000 |

EWR270 | ||||

EWR300 | ||||

EWR360 | ||||

EWR400 | ||||

EWR500 | ||||

EWR600 | ||||

EWR800 |

Special specification can be produce according to customer requirements.

4.FAQ

Packaging:

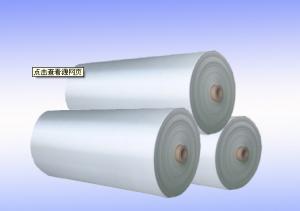

Each woven roving is wound onto a paper tube which has an inside diameter of 76mm and the mat roll has a diameter of 220mm. The woven roving roll is wrapped up with plastic film,and then packed in a cardboard box or wrapped up with kraft paper. The rolls can be horizontally placed. For transportation, the rolls can be loaded into a cantainer directly or on pallets.

Storage:

Unless otherwise specified,It should be stored in a dry, cool and rain-proof area. It is recommended that the room temperature and humidity should be always maintained at 15℃~35℃ and 35%~65% respectively.

- Q: How does fiberglass mat tissue perform in high temperatures?

- Due to its inherent heat resistance properties, fiberglass mat tissue is highly effective in high temperatures. The mat is crafted from woven glass fibers, creating a durable and sturdy material. These glass fibers possess a high melting point, enabling the fiberglass mat tissue to endure elevated temperatures without distorting or compromising its structural integrity. Unlike other materials, fiberglass mat tissue does not shrink, warp, or become brittle when exposed to high temperatures. It maintains its dimensional stability and mechanical strength, making it suitable for a wide range of applications in industries such as automotive, aerospace, construction, and insulation. Furthermore, fiberglass mat tissue acts as a thermal insulator, providing protection against heat transfer. It effectively resists heat conduction and radiation, assisting in maintaining the desired temperature in a given environment or preventing heat damage to nearby components. Moreover, fiberglass mat tissue is non-combustible, meaning it does not burn or release toxic gases when subjected to fire. This characteristic makes it a dependable choice for applications that necessitate fire resistance, such as fireproofing insulation or protective barriers. In conclusion, fiberglass mat tissue excels in high temperatures. Its heat resistance, dimensional stability, mechanical strength, thermal insulation properties, and non-combustible nature establish it as an outstanding material for demanding environments where elevated temperatures are present.

- Q: Is fiberglass mat tissue suitable for insulation in chemical processing plants?

- Yes, fiberglass mat tissue is suitable for insulation in chemical processing plants. Fiberglass mat tissue is made from fine glass fibers bonded together with a binder, which gives it excellent thermal insulation properties. It can withstand high temperatures and is resistant to many chemicals, making it ideal for use in chemical processing plants where there may be exposure to corrosive substances or high heat. Additionally, fiberglass mat tissue is lightweight and easy to install, making it a cost-effective choice for insulation in these types of industrial environments.

- Q: Can fiberglass mat tissue be used for repairing fiberglass shower stalls?

- Yes, fiberglass mat tissue can be used for repairing fiberglass shower stalls. It is a commonly used material for reinforcing and repairing fiberglass surfaces, including shower stalls.

- Q: What are the different finishing options available for fiberglass mat tissue?

- There are several different finishing options available for fiberglass mat tissue. One common finishing option is a resin coating. This involves applying a layer of resin to the surface of the fiberglass mat tissue. The resin helps to protect the fibers and provide added strength and durability. It can also improve the appearance of the material, giving it a smooth and glossy finish. Another finishing option is a fire-retardant treatment. This involves applying a special chemical treatment to the fiberglass mat tissue that helps to reduce its flammability. This is especially important in applications where fire safety is a concern, such as in the construction industry. Additionally, fiberglass mat tissue can be finished with a colored pigment. This involves adding a dye or pigment to the material during the manufacturing process. This allows for a wide range of color options, making the fiberglass mat tissue more visually appealing and versatile. Some manufacturers also offer a textured finish for fiberglass mat tissue. This involves adding a pattern or texture to the surface of the material, creating a more tactile and aesthetically pleasing product. This can be particularly useful in applications where grip or slip resistance is required. Lastly, fiberglass mat tissue can be finished with a laminated backing. This involves bonding the fiberglass mat tissue to a separate backing material, such as foam or fabric. This provides additional strength and flexibility to the material, making it suitable for a wider range of applications. Overall, the different finishing options available for fiberglass mat tissue allow for customization and adaptation to specific needs and requirements. Whether it's adding strength, fire resistance, color, texture, or additional backing, these finishing options enhance the performance and appearance of fiberglass mat tissue in various industries.

- Q: What are the typical roll sizes available for fiberglass mat tissue?

- The manufacturer and specific application determine the varying sizes of fiberglass mat tissue rolls. Generally, they range in width from 50 inches to 120 inches and in length from 100 yards to 1,000 yards. These sizes are frequently utilized in construction, automotive, and marine industries for purposes such as insulation, reinforcement, and soundproofing. It should be emphasized that the availability of particular roll sizes may vary depending on the supplier and the intended use of the fiberglass mat tissue.

- Q: Can fiberglass mat tissue be used for making electrical enclosures?

- No, fiberglass mat tissue is not suitable for making electrical enclosures. Electrical enclosures require materials that have good electrical insulation properties to prevent electrical shocks and short circuits. Fiberglass mat tissue is primarily used for reinforcement in composites and does not possess the necessary electrical insulation properties. Materials such as plastics, polymers, or metals with appropriate electrical insulation characteristics should be used for making electrical enclosures.

- Q: What are the recommended storage and handling practices for fiberglass mat tissue?

- To ensure the integrity and longevity of fiberglass mat tissue, it is necessary to adhere to a few recommended practices. 1. Storage: Fiberglass mat tissue should be stored in a clean, dry environment to prevent damage from moisture or dirt. Ideally, it should be kept indoors, away from direct sunlight and extreme temperatures. 2. Handling: Proper handling is crucial to avoid damaging the delicate material. It is advisable to wear protective gloves and safety glasses to prevent injuries. Care should be taken to handle it gently, avoiding any tears or creases that may compromise its performance. 3. Transportation: During transportation, it is essential to pack fiberglass mat tissue securely to minimize the risk of damage. Adequate protection should be provided to prevent impact or vibration. If possible, it is preferable to transport it in a dedicated vehicle or container for added safety. 4. Avoid chemical contact: Fiberglass mat tissue should not come into contact with chemicals such as acids, alkalis, or solvents. These substances can degrade and weaken the material. Clean hands should be used when handling, and contact with harmful substances should be avoided. 5. Follow manufacturer's guidelines: It is advisable to adhere to the specific recommendations provided by the manufacturer regarding storage and handling. Different manufacturers may have slightly different requirements, and following them ensures optimal performance and longevity. By adhering to these recommended practices for storage and handling, the integrity of fiberglass mat tissue can be maintained, guaranteeing its readiness for its intended use.

- Q: Can fiberglass mat tissue be used for composite panel manufacturing?

- Yes, fiberglass mat tissue can be used for composite panel manufacturing. Fiberglass mat tissue is a thin and lightweight material that is typically made from randomly oriented fiberglass strands bonded together with a binder. It is commonly used as a reinforcement material in composite manufacturing processes. When used in composite panel manufacturing, fiberglass mat tissue is typically combined with other materials such as resin and a core material to create a strong and durable panel. The mat tissue provides reinforcement and strength to the panel, helping to distribute loads and prevent cracking or delamination. Fiberglass mat tissue is known for its excellent tensile strength, dimensional stability, and resistance to chemicals, making it well-suited for use in composite panel manufacturing. It can be used in a variety of applications, including construction, transportation, marine, and aerospace industries. Overall, fiberglass mat tissue is a versatile and effective material that can be successfully used in the manufacturing of composite panels. Its properties and characteristics make it a reliable choice for creating strong and durable panels for various applications.

- Q: Can fiberglass mat tissue be used for repairing fiberglass canoes?

- Yes, fiberglass mat tissue can be used for repairing fiberglass canoes. It is commonly used to reinforce and strengthen the damaged areas of the canoe by providing additional structural support.

- Q: Is fiberglass mat tissue resistant to mildew and rot?

- Yes, fiberglass mat tissue is resistant to mildew and rot.

Send your message to us

Fiberglass Mat Tissue - E Glass Fiber Woven Roving (200gsm-800gsm)

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 16000 kg

- Supply Capability:

- 160000Kg Per Month kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords