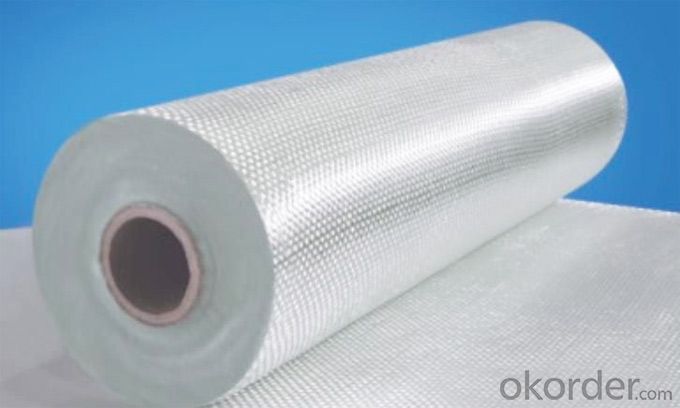

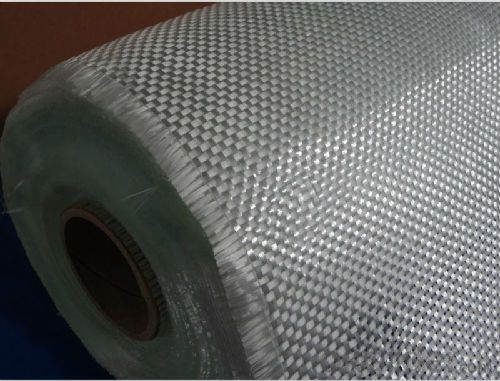

Fiberglass Glass Fiber Woven Roving

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10Ton kg

- Supply Capability:

- 100TON PER MONTH kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Woven roving is a bidirectional fabric made by roving in plian weave pattern. The construction impants to the fabric an excellent dimensional stability during handling. Woven roving is a high-performance reinforcement and widely used in hand and machine procuction, such as boats,vessels,planes and automotive parts,furniture and sports facilities,and other fields

| Item | Warp Density Ends/cm | Weft Density Ends/cm | Weight G/m2 |

| EWR270 | 46 | 41 | 270±14 |

| EWR300 | 32 | 18 | 300±15 |

| EWR360 | 32 | 18 | 360±18 |

| EWR400 | 23 | 22 | 405±20 |

| EWR500A | 22 | 20 | 504±25 |

| EWR500 | 20 | 16 | 520±26 |

| EWR580 | 26 | 22 | 580±29 |

| EWR600B | 20 | 16 | 620±31 |

| EWR600C | 28 | 20 | 600±30 |

| EWR600D | 20 | 20 | 610±31 |

| EWR800B | 20*2 | 16*2 | 850±43 |

| EWR800C | 28 | 20 | 840±42 |

| EWR800D | 20*2 | 12*2 | 847±42 |

| EWR800 | 20*2 | 15*2 | 840±42 |

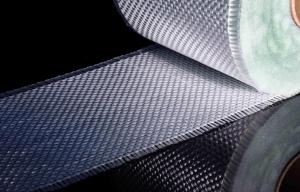

Applications

1.Elementary material of FRP with anticorrosion and insulation.

2.Fireproofing and waterproof use.

3.Mainly applied in the production of boats, fiberglass pipes, containers and sports equipment

4.Applied in the automobile parts, furniture, fiberglass reinforced plastic product, etc.

Features

1.Warp and weft rovings aligned in a parallel, flat manner and uniform tension

2.Densely aligned fibers, providing high dimensional stability and easy handing

3.Good moldabllity, fast and complete resin wet-out, enabling high productivity

4.Good transparency and high strength of the composite products

Packaging & Delivery

Packaging Detail:carton+pallet

Delivery Detail:acording to customer's request

- Q: What is the production process of FRP grille?

- Reciprocating fiber winding technology (belonging to the fixed length method): in this process, dipping tank with mandrel rotating reciprocating motion, long fiber glass fiber with a certain angle relative to the mandrel axis auxiliary, auxiliary angle (i.e. winding angle) by dipping groove movement speed and mandrel speed ratio control, control of electric glue impregnation groove translational motion by a computerized machine. The number of plies increases gradually to the wall thickness of the design. When the winding is finished, the resin in the product is basically solidified. After solidification, the core die is removed from the glass tube.

- Q: A chromic acid concentration and what kind of glass?reinforced?plastics should be used in chromic acid waste gas purification and recovery device.

- Glass fiber reinforced plastic containing silicon is recommended.

- Q: Formula of glass fiber yarn

- It is usually known as the short fiber. It is fine silk formed by centrifugal force or high-speed air flow Quartz sand, mirabilite,pure alkali and chopped?strand. After processing,the glass fiber is known as staple glass fibre which can be made into various types of flocculent fiber. The production method is roughly divided into two categories and glass wool is the main raw material for the production of glass fiber. Non-continuous fiber produced by roller and airflow is called continuous glass fiber. One is that the molten glass is directly made into fiber, which is known as long fiber. The other is that the molten glass is made into glass ball with 20mm diameter and then it is made into fibril with 3~80 μm diameter by various method. Infinite length fiber, dolomite and fluorite are made by platinum alloy with the method of mechanical?wiredrawing.

- Q: The safe operation of glass fiber twisting frame

- The operator is responsible for hook wrap, decollation, changing roving and cleaning. Doffer is responsible for cleaning. Both of them needs skills.

- Q: Does centrifugal glass wool is made from glass fiber

- No, it doesn't. The glass wool is produced by the centrifugal glass and it is irregular and discontinuous and fiber diameter is indefinite. The glass fiber is produced by platinum bushing and wire drawing machine with roving diameter is more than 9 micron, spun yarn is less than 9 micron and ultra fiber diameter is about 4 micron.

- Q: The manufacturing technique and process of glass fiber

- What is the thickness of chemical industry glass fiber winding pipe and chemical industry standard deviation?

- Q: What is the difference between the glass and glass?reinforced?plastics?

- Glass and glass?reinforced?plastics is totally different two things.Generally speaking, glass?reinforced?plastics is a kind of plastics with cloth or felt made by glass fiber as reinforced plastics.

- Q: What is the material of glass steel? How to make it?

- Glass fiber reinforced plastic is a kind of composite material. It is common in everyday life. As a typical composite material, it is made by glass fiber and epoxy resin. In general, the glass fiber should be woven into a glass cloth, and then mix with the epoxy resin, the glass fiber reinforced plastic can be made after expoxy resin solidition. Epoxy resin itself is toxic, but the chemical properties is stable, and it is not harmful to human after solidation.

- Q: What kind of knife can used to cut glass wool cloth?

- The mix proportion of epoxy resin and mortar is that 6101epoxy resin: ethylenediamine: cement: sand is equal to 100:15:8:200:500. 1 base dispose, 1)a vertical fissure is formed along the crack gouge, vertical cracks cut into 2 surface treatment, Siyou cloth with its surface sticking epoxy base fluid and glass silk cloth is used for surface treatment ( in which oil used is epoxy liquid, and cloth is glass?silk cloth). 1) process of glass silk cloth. Glass cloth generally usually made by alkali-free glass fiber is twistless roving woven cloth. Wetting agent are added in the production process of glass silk cloth. As wetting agent contains grease and wax which will impact the combination of epoxy base fluid and glass silk cloth, it is necessary to remove oil and wax on glass silk cloth in order to make epoxy base fluid immerse in glass fiber, improving the bonding effect. The method for removing wax and oil is to place glass silk cloth in boiling water containing with soda for an hour, then you should blanching it with clean water. the way to judge whether there is oil and wax on glass silk cloth is to touch and feel it. If you feel like it is not greasy, it is clean. After removing oil and wax, glass silk cloth losts its original white and brightness appearance and its weight also reduces correspondingly. 2) paste process. When pasting, you should brush epoxy resin base fluid evenly on the paste face, then you should brush the second layer with the same way.

1. Manufacturer Overview

| Location | Zhejiang, China |

| Year Established | 1969 |

| Annual Output Value | Above US$ 150 Million |

| Main Markets | overseas companies in Hongkong, Canada, South Africa, South Korea, India, Italy, Singapore, France and many other countries and regions. |

| Company Certifications | ISO9001;ISO14001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 40%-50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English |

| b) Factory Information | |

| Factory Size: | Above 5000,000 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | |

| Product Price Range | Average |

Send your message to us

Fiberglass Glass Fiber Woven Roving

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10Ton kg

- Supply Capability:

- 100TON PER MONTH kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords