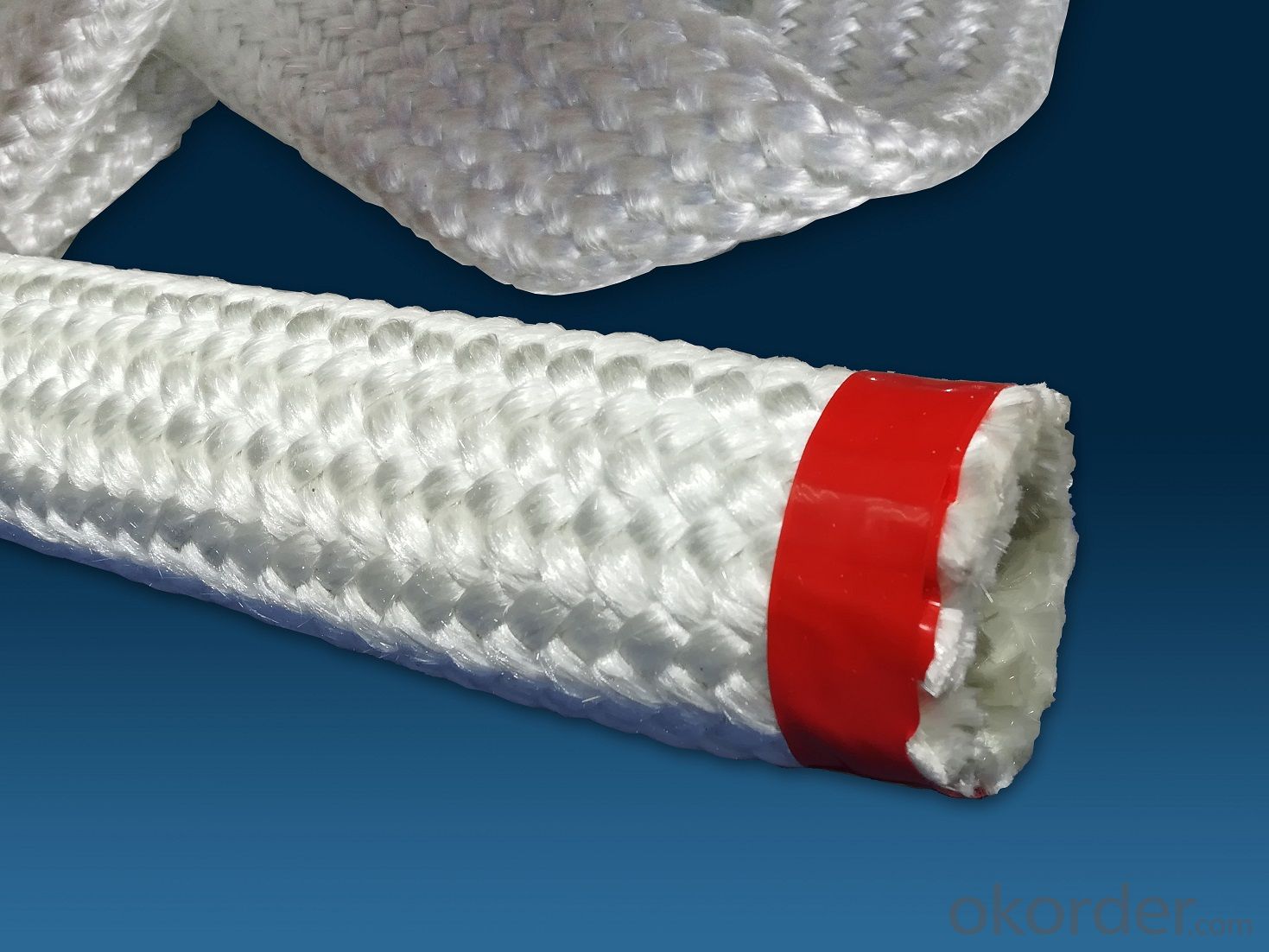

Woven Roving Fiberglass 1200 High Temperature Resistance Braided Rope

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 5000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Image:

Product Description & Application:

Fiberglass square Braided rope is rope-shape high-temperature products woven by glass fiber yarn.

Application:

Sealing for industrial door, pit kiln, boiler, chimney door;

Thermal insulation for high temperature pipe and vessel;

Sealing for petrochemical industry soft pipe;

Sealing for valves, pumps and exchange equipment.

Product Capability:

High temperature resistant, thermal insulation, soft, smooth, low thermal conductivity;

Thermal insulation and chemical stability;

Nontoxic and harmless to the environment.

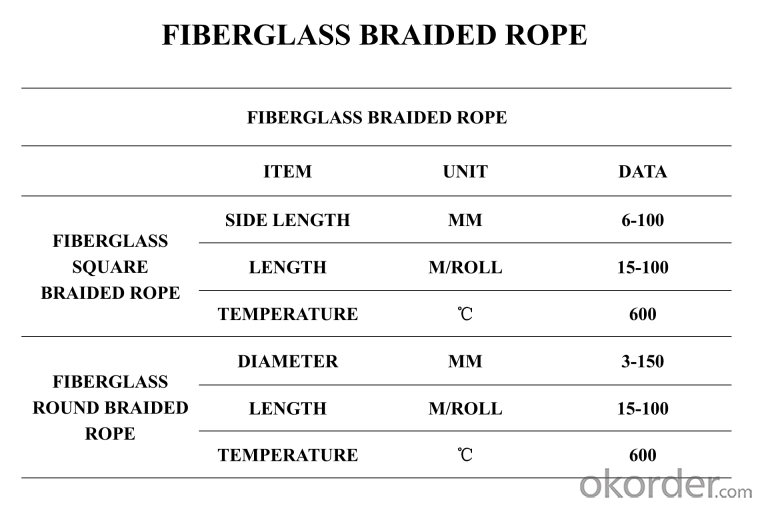

Data Sheet:

:

Fiberglass products:

Fiberglass is a kind of long fiber. It has the advantage of high tensile strength, low thermal conductivity, corrosion resistance and good insulation.The working temperature ranges from 200-1000 degree Celsius. Main products: Fiberglass texturized yarn, cloth, tape, rope, sleeve,mesh,filter cap,friction thread (piece) and fiber netting,composite yarn etc.

- Q: What does the basalt fiber do?

- According to its characteristics, it is a very wide range of industrial raw materials. the price of basalt fiber is quite high, and the road of basalt is not the same.

- Q: Knowledges of bamboo fiber.

- So it needs special equipment for processing, but because the bamboo fiber is very short, the most notable feature is the environmental protection and decontamination capability. At present, it is mainly used in textile products. There is an association of bamboo fiber, where phyllostachys pubescens (General requirements for three years) is soaked and peeled, almost like paper-making.

- Q: How to make GRC line?

- The basic composition of GRC materials are cement, sand, fiber and water, in addition to polymer, additives used to improve the later performance of the materials. Cement: Usually the cements used in GRC are mainly rapid hardening sulphoaluminate cement and low alkalinity sulphoaluminate cement, Portland cement and white Portland cement. Fiber: The fiber in the GRC material must be alkali resistant glass fiber, which include alkali resistant glass fiber roving, chopped glass fiber yarn, alkali resistant glass fiber mesh cloth. European and American countries require the zirconia content in the glass fiber should not less than 16.5%. The polymer: the polymer usually added is acrylic emulsion, also named acrylate copolymer emulsion. Additive: Usually we selectively added superplasticizer, superplasticizer, retarder, early strength agent, antifreeze, anti rust agent and other additives containing products. When there is the steel reinforcement or steel embedded parts, do not use calcium chloride based additives. Other materials: We can selectively use fire. The basic composition of GRC materials are cement, sand, fiber and water, in addition to polymer, additives used to improve the later performance of the materials. Cement: Usually the cements used in GRC are mainly rapid hardening sulphoaluminate cement and low alkalinity sulphoaluminate cement, Portland cement and white Portland cement. Fiber: The fiber in the GRC material must be alkali resistant glass fiber, which include alkali resistant glass fiber roving, chopped glass fiber yarn, alkali resistant glass fiber mesh cloth. European and American countries require the zirconia content in the glass fiber should not less than 16.5%. The polymer:

- Q: How many specifications of glass fiber?

- According to fiber diameter, there are many varieties and specifications and spun yarn is used for industry and electron in term of application. There are many specifications including E series, G series, D series and H series.

- Q: What are the causes and methods of glass fiber surface treatment?

- Pretreatment method: the surface treatment agent is added to the formula of glass fiber soakage agent, which is processed in drawing process (mainly used for roving and its textile products).

- Q: What type of cement is used in the common GRC component?

- Of course, the low alkali rapid hardening sulphoaluminate cement is good, but we do not use it as the cost increased, and the additive is double glass fiber mesh cloth. Cememt ans sand shall be simple packed. If it is the large mount, we could use machine for production

- Q: What materials are used to the special grid plate of the carwash?

- We call it geogrids with the frame made by the glass fiber twistless roving. The matrix is mainly unsaturated polyester resin

- Q: what are the material used for GRC decorative lines

- Cement, sand, glass fiber. We should pay attention to anti-cracking in interior decoration.

- Q: What is glass fiber extrusion

- Glass fiber extruding machine set can be used to produce different shapes of glass fiber reinforced plastics in different shapes, which can be formed by the oven traction machine oil pump station and so on.

Send your message to us

Woven Roving Fiberglass 1200 High Temperature Resistance Braided Rope

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 5000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords