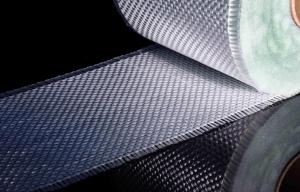

High Quality Roving Fiberglass Tape Woven Roving

- Loading Port:

- Shanghai Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 M2 m²

- Supply Capability:

- 50000000 M2 Per Year m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Fiberglass Woven Roving:

Fiberglass Woven Roving is mainly shuttle woven, producing an excellent appearance and using high performance. It is widely used in aircraft and space flight industry, ship industry, chemical industry, medical industry, military industry, sports goods, etc. It is available in manufacturing FRP fishing pole, golf pole, baseball bole, surfboard, sailboard, skis, ice stick, etc.

Application of Fiberglass Woven Roving:

a) boats ,vessels ,plane

b) automotive parts ,furniture and sports facilities

c) resins system,such as polyester,viny ester and epoxy resins

Technical Parameters of Fiberglass Woven Roving:

Product No. | Density Ends/cm | Area Weight | Thickness | Width | Length | Breaking Strength(N) ≥ | ||

| ||||||||

Warp/cm | Weft/cm | g/M2 | Warp | Weft | ||||

EWR260 | 22 | 22 | 251-277 | 0.26 | 10~100 | 50~200 | 1100 | 900 |

EWR270 | 46 | 41 | 248-274 | 0.26 | 10~100 | 50~200 | 1800 | 1100 |

EWR300 | 32 | 18 | 296-328 | 0.3 | 10~100 | 50~200 | 1500 | 1100 |

EWR360 | 32 | 18 | 336-372 | 0.35 | 10~100 | 50~200 | 2000 | 1100 |

EWR400 | 32 | 23 | 400-430 | 0.4 | 10~100 | 50~200 | 2500 | 2200 |

EWR580 | 26 | 22 | 580-610 | 0.58 | 10~100 | 50~200 | 3850 | 3650 |

EWR600 | 20 | 16 | 600-645 | 0.6 | 10~100 | 50~200 | 4000 | 3850 |

EWR800 | 20 | 15 | 800-840 | 0.8 | 10~100 | 50~200 | 4600 | 4400 |

- Q: Knowledges of bamboo fiber.

- So it needs special equipment for processing, but because the bamboo fiber is very short, the most notable feature is the environmental protection and decontamination capability. At present, it is mainly used in textile products. There is an association of bamboo fiber, where phyllostachys pubescens (General requirements for three years) is soaked and peeled, almost like paper-making.

- Q: What parameters should be provided for the customs clearance of the glass fiber?

- 1 name 2 material (fiberglass) 3 types (sliver, roving , yarn, short fiber) 4 length

- Q: Model parameters of glass fiber reinforced plastic and glass fiber cloth

- The materials for strengthen are Medium, vinyl type and flame retardant, vinyl resin. There are many types of materials like phthalate, benzene, alkali free glass fiber roving, knitted mat etc.: polyester resin

- Q: The manufacturing technique and process of glass fiber

- In general, woven cloth can be produced into roving, twisted or twistless yarn by simply weaving or piecing together. On the basis of the yarn, quartz sand is used as the main raw material to produce fiber cloth by tank furnace, melting or wire drawing.

- Q: What are the differences between glass fiber and asbestos?

- Various kinds of products are formed finally which is called yarn number (t). The content of chrysotile is the most abundant. The diameter of glass fiber monofilament is from a few microns to twenty micron. 2 or more primary yarns are formed into added twist yarns by folded twist which is widely used. Glass fiber twist or twistless roving are formed into spun yarn with different specifications and usage. There mainly are alkali free. Composite line is formed by two or more fold twist. Glass fiber is a kind of inorganic nonmetal material with excellent performance. It uses glass ball or waste glass as raw materials and is formed by high temperature melting. It mainly is used for producing glass?fiber products. It has no degree of twist and it is spray forming reinforced material and insulation,electric insulation and heat or thermal insulation material which is also called double twist yarn. It mainly is used for hand lay-up glass?reinforced?plastics and is known as detwisting yarn in glass fiber industry. The meaning of metric system number. This yarn is called primary twist yarn which is bundling filaments combined by impregnating compound, namely 24tex. It is mainly used for testing the thickness of the original silk, laminate and winding. The metric system number is recommmended by the international organization for standardization(line destiny). 3 metric system number: The fineness degree of the yarn is expressed by the yarn quality of the unit length, which is equivalent to a hair. The smaller the number is, the thicker the yarn is. Monofilament is equal to 20tex. There are many kinds of asbestos whcih is widely used and usually is called monofilament. The former is a fixed length, the latter is a fixed weight.

- Q: Definition of glass fiber reinforced plastic doors and windows

- The unsaturated resin is used as the subtrate material. it have many advantages such as sound insulation and so on. Glass?reinforced?plastics is also called glass fiber reinforced material with lightweight property. Glass?reinforced?plastics doors and windows use glass fiber twistless roving and fabric as reinforcement material. It is a new type of composite material developed abroad in early twentieth Century and can add other mineral filler.

- Q: Does glass wool belongs to glass fiber cloth?

- No, glass wool belongs to the one category of glass fiber and it is a kind of artificial inorganic fiber. Glass fiber cloth is twistless roving plain fabric made by glass fiber cloth.

- Q: Production process of glass fiber reinforced plastic

- Technology of fiber reinforced epoxy resin composite, compared to traditional materials has a series of alternative properties since two technology are developing fastly. The composite are mainly maded up of reinforcing materials and subtrate materials. Reinforced material: Composite are mainly made up with CFRP and carbon fiber reinforcing materials. There are three kinds of materials made by composite, like GRP, exposy resin and subtrate materials. In this paper, epoxy resin composites use epoxy resin matrix, with the low curing shrinkage rate only 1%-3% and high saturated polyester resin, as high as 7%-8% and good adhesion; B phase is benefit to the production process; low curing volatile low curing stress; the performance of chemical resistance, good electrical insulation performance value ring oxygen resin solvent, alkali resistant machine performance compared with full power and phenolic acid polyester fat good; curing as a brittle, poor toughness 2 epoxy glass steel (ASTM) FW (fiber) epoxy resin and its products with steel manufacturing glass fiber enhanced

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 2002 |

| Annual Output Value | Below US$1 Million |

| Main Markets | North America; South America; Eastern Europe; Southeast Asia; Africa; Oceania; Mid East; Eastern Asia; Western Europe; Central America; Northern Europe; Southern Europe; South Asia |

| Company Certifications | ISO 9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port |

| Export Percentage | 81% - 90% |

| No.of Employees in Trade Department | Above 10 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 10,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

High Quality Roving Fiberglass Tape Woven Roving

- Loading Port:

- Shanghai Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 M2 m²

- Supply Capability:

- 50000000 M2 Per Year m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords