Geogrids Price for Fiberglass Geogrid Applied for Soil Reinforcement

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Geogrid Applicated for Soil Reinforcement

Description Of Fiberglass Geogrid Applicated for Soil Reinforcement:

Fiberglass geogrid is a kind of new favorable earthwork base material to strengthen the road surface and roadbed.This product is made by weaving and covering fiberglass filament. It is featured by high vertical and horizontal tensile strength,low unit extension, high flexibility, and favorable high and low temperature resistance.The products after surface covering own the favorable property of alkali resistance and aging resistance. It is used widely to increase the asphalt road surface, concrete road and roadbed (both soft and hard road surfaces).Compared with the traditional road surface, it reduces the cost, prolong the service life, and avoid the reflection road crackle.This product is also used to strengthen the soft land, such as railway, airport, irrigation work, and dyke, etc, and the roadbed.

Main Features of Fiberglass Geogrid Applicated for Soil Reinforcement:

(1)High tensile strength in both the vertical and horizontal directions;

(2)Low elongation;

(3)Excellent temperature ;

(4)Good anti-age and alkali-resistance;

(5)Reduce construction cost, extend service life of road and prevent deflection cracks.

This product is formed by weaving and covered with aphalt or PVC.

Specifications of Fiberglass Geogrid Applicated for Soil Reinforcement:

Tensile Strength (KN) | Warp | >30 | >50 | >60 | >80 | >100 | >120 | >150 | >200 |

Weft | >30 | >50 | >60 | >80 | >100 | >120 | >150 | >120 | |

Elongation(%) | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | |

Mesh Size(mm) | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | |

Elastic Modulus | 76 | 76 | 76 | 76 | 76 | 76 | 76 | 76 | |

Width(m) | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | |

Length(m) | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | |

Temperature Resistant(℃) | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | |

Resin Content (%) | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | |

Glue Type | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | |

Applications of Fiberglass Geogrid Applicated for Soil Reinforcement:

1.It reinforced old asphalt concrete road surface and asphalt surface layer ,and prevents damage

2.It is used for rebuilding cement concrete road surface into composite road surface and restraining reflection caused by block contraction

3.It is used inroad expansion and improvement project and crack by old and new combination position and uneven sedimentation

4.It is used in soft soil base reinforcement treatment ,is favorable for soft soil water separation and concretion ,restrains sedimentation effectively ,distributes stress uniformly and improve overall strength of road base

5.It is used for preventing contraction crack caused by new road semi-rigid base layer , and reinforcing and preventing road

surface crack caused by foundation crack reflection .

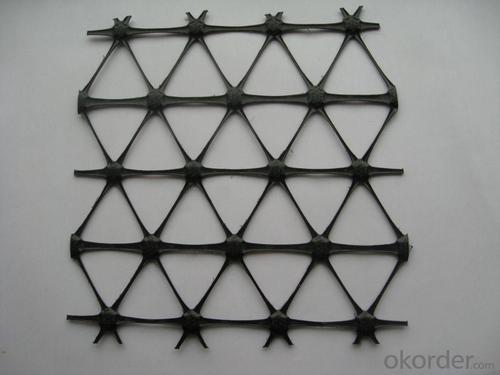

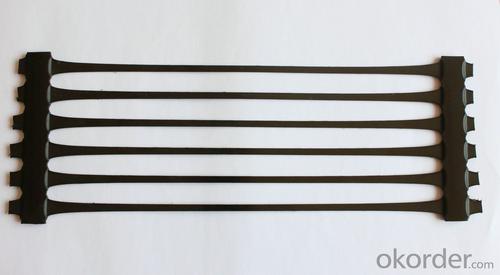

IMages of Fiberglass Geogrid Applicated for Soil Reinforcement:

FAQ of Fiberglass Geogrid Applicated for Soil Reinforcement:

1. What are we supplying?

We are specialized in producing Geosynthetic materials, like Geogrid Series, HDPE Geocell, Geonet, Geotextile, Geomat, Tri Denmensional Composite Grainage Geonet, and Geomembrane Series.

.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: What is the role of Geogrid

- 3, geogrid for the construction of convenient, time-saving, labor-saving, shorten the construction period, reduce maintenance costs.

- Q: What is a geotextile mattress?

- Composite geotextile is also called soft mattress, soft soft row row. The upper filter geotextile layer, lower layer woven cloth layer, upper and lower two layers sewn into several units, each unit filling sand is formed around the main rib and frame shape auxiliary rib, the main vertical rib in the flow direction, the auxiliary rib along the flow direction, the composite geotextile soft volleyball has the advantages of good flexibility, in the process of riprap, can automatically adjust the overall shape, form a good protective line and the bearing capacity of stone, with good protection function

- Q: What are the criteria for the use of plastic geogrid

- Warp knitted grating, steel plastic grille, plastic grille, fiberglass grille

- Q: Do geogrids affect soil drainage?

- Yes, geogrids can affect soil drainage. Geogrids are typically used to reinforce soil and improve its stability. However, their presence can also impact the movement of water through the soil. Depending on the design and installation of the geogrids, they can either enhance or inhibit soil drainage.

- Q: Glass fiber mesh cloth.

- Mesh is based on alkali or alkali glass fiber yarns, the alkali resistant polymer emulsion coated glass fiber mesh cloth series products: GRC alkali resistant fiberglass mesh cloth, alkali resistant wall enhanced special mesh and stone mosaic, marble back mesh cloth

- Q: How do geogrids improve the performance of bridge abutments?

- Geogrids improve the performance of bridge abutments by providing reinforcement and stability to the surrounding soil. They act as a barrier against soil movement, preventing erosion and settling, which can cause damage to the abutments. Additionally, geogrids distribute the load more evenly, reducing stress concentration and increasing the overall strength of the bridge abutments.

- Q: What is the single geogrid 60kN/m

- 60kN/m refers to the direction of force.

- Q: Fiberglass grille and geogrid which use more

- Geogrid is divided into four categories: plastic geogrid, steel plastic geogrid, fiberglass geogrid and fiberglass polyester geogrid. The glass fiber geogrid belongs to the geogrid, which is more natural than the glass fiber geogrid.

- Q: Do geogrids require any maintenance?

- Yes, geogrids typically do not require any maintenance once they are properly installed. They are designed to be durable and withstand the elements, so they generally do not need any regular upkeep or repairs.

- Q: High strength geogrid reinforced cloth, steel plastic grille, PET polyester grille, PP welded geogrid, steel plastic composite tensile band, where are these geosynthetics produced?

- Geogrid is divided into four categories: plastic geogrid, steel plastic geogrid, fiberglass geogrid and polyester polyester geogrid.Turn left and turn right |

Send your message to us

Geogrids Price for Fiberglass Geogrid Applied for Soil Reinforcement

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords