FRP Pultrusion Profiles - Best Composites Fiberglass Products FRP Grating with High Quality/Modern Type

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

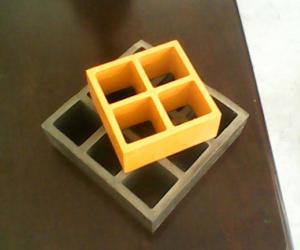

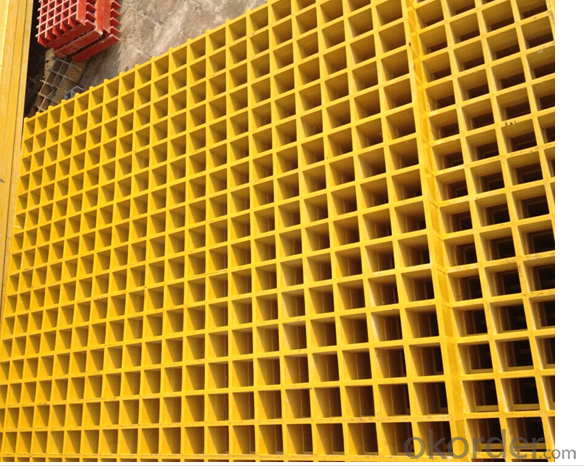

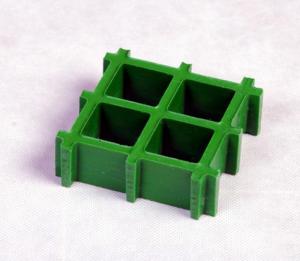

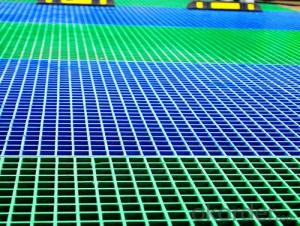

FRP Molded Grating is a structural panel which uses high-strength E-Glass roving as reinforcing material, thermosetting resin as matrix and then casted and formed in a special metal mold. It provides properties of light weight, high strength, corrosion resistance, fire resistance and anti-skid. FRP Molded Grating is widely used in oil industry, power engineering, water & waste water treatment, ocean survey as working floor, stair tread, trench cover, etc. and is an ideal loading frame for corrosion circumstances.

Feature

Corrosion Resistance

Fire Resistance

Light Weight & High Strength

Safety & Anti-slip

Electrical Insulating

Aging Resistance

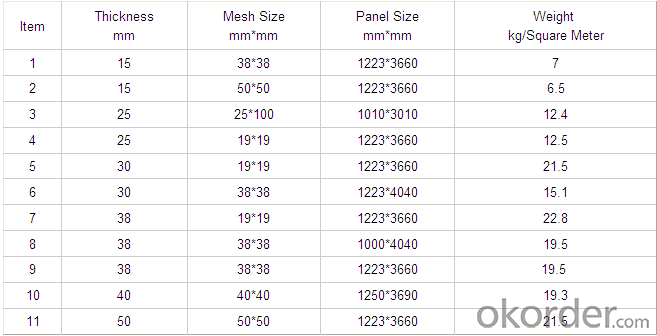

Specification

Advantage

coated with prevent aging layer

excellent insulating performance

no maintenance

high strength

long service life

easy installation

Application

Power plants, substation equipment enclosures, antimagnetic, anti-static,to prevent small animals into the equipment failure, as there is electricity facilities and without power interval intervals.

In high voltage electrical equipment for power line work, in order to prevent workers go wrong location, charged interval or near electrically charged equipment to dangerous distance.

Pool railings in sewage treatment industry

- FAQ

1. How's the payment?

Telegraphic Transfer(T/T) or Letter of Credit(L/C)

2. Do You Arrange Shipment?

Yes, dear esteemed customers, for FOB or CIF price, we will arrange shipment for you. For EXW price, clients need to arrange shipment by themselves or their agents.

3. How is the package?

Usually, we arrange the standard out-package for exporting.

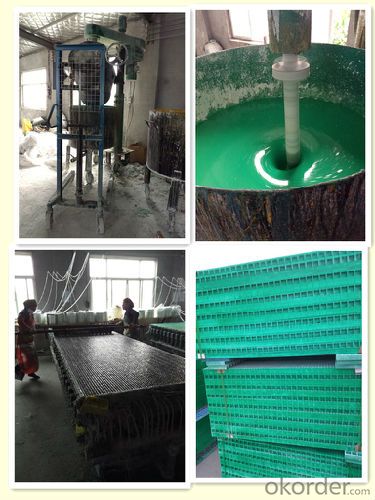

FACTORY

- Q: Can FRP pultrusion profiles be used in the construction of pedestrian tunnels?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the construction of pedestrian tunnels. FRP profiles offer several advantages such as high strength-to-weight ratio, corrosion resistance, and durability, making them suitable for tunnel construction. Additionally, FRP profiles can be easily customized to meet specific design requirements and offer long-term cost savings due to their low maintenance needs.

- Q: Can FRP pultrusion profiles be used in the construction of solar panel frames?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the construction of solar panel frames. FRP pultrusion profiles are lightweight, strong, and resistant to corrosion, making them an ideal material choice for solar panel frames. The durability and high strength-to-weight ratio of FRP pultrusion profiles ensure that the frames can withstand various weather conditions and long-term exposure to sunlight. Additionally, FRP pultrusion profiles can be easily customized to meet specific design requirements, allowing for flexibility in the construction of solar panel frames. Overall, the use of FRP pultrusion profiles in solar panel frame construction offers numerous advantages, making it a suitable choice for the solar energy industry.

- Q: Are FRP pultrusion profiles resistant to fungal growth?

- FRP pultrusion profiles are generally resistant to fungal growth. The composite materials, like resins and fibers, used in pultrusion possess inherent resistance to biological degradation, including attacks from fungi. The non-porous nature of FRP pultrusion profiles also poses difficulties for fungi to penetrate and grow on the surface. Furthermore, the manufacturing process involves curing the composite materials at high temperatures, which adds to their resistance against fungal growth. However, it is important to acknowledge that no material is entirely impervious to fungal growth in all conditions. Factors such as high humidity, prolonged exposure to moisture, and inadequate maintenance practices can still contribute to fungal growth on FRP pultrusion profiles, albeit to a lesser extent compared to materials like wood or metal. Regular inspection and appropriate cleaning are crucial to sustain the fungal resistance of FRP pultrusion profiles throughout their lifespan.

- Q: Are FRP pultrusion profiles resistant to moisture or humidity?

- FRP pultrusion profiles boast exceptional resistance to moisture and humidity. Through the pultrusion process, continuous fibers are thoroughly saturated with a polymer resin, resulting in a steadfast and enduring composite material. This composite possesses inherent moisture resistance, differing from conventional materials like wood or metal, as it does not absorb water. Moreover, FRP pultrusion profiles exhibit a minimal coefficient of thermal expansion, minimizing the likelihood of expansion or contraction in response to varying humidity levels. This moisture and humidity resistance render FRP pultrusion profiles suitable for a diverse array of applications, including outdoor structures, marine environments, and other areas prone to moisture.

- Q: What are the typical lifespan of FRP pultrusion profiles?

- The typical lifespan of FRP pultrusion profiles can vary depending on various factors such as the specific application, environmental conditions, and maintenance practices. However, on average, FRP pultrusion profiles can have a lifespan ranging from 20 to 50 years.

- Q: Can FRP pultrusion profiles be used in the oil and gas industry?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the oil and gas industry. FRP pultrusion profiles offer several advantages that make them suitable for applications in this industry. Firstly, FRP pultrusion profiles are corrosion-resistant. They do not rust, corrode, or degrade when exposed to harsh environments, such as saltwater, chemicals, and extreme temperatures. This makes them ideal for use in offshore platforms, pipelines, and other oil and gas facilities where corrosion can be a significant issue. Secondly, FRP pultrusion profiles have high strength-to-weight ratio. They are lightweight yet extremely strong, allowing for efficient installation, transportation, and handling. This is particularly beneficial in the oil and gas industry, where weight reduction is a crucial factor in improving operational efficiency and reducing costs. Thirdly, FRP pultrusion profiles can be customized to meet specific requirements. They can be manufactured in various shapes, sizes, and configurations, making them versatile for different applications in the oil and gas industry. Whether it is for structural supports, grating, handrails, or other components, FRP pultrusion profiles can be tailored to fit the specific needs of each project. Furthermore, FRP pultrusion profiles offer excellent electrical insulation properties. This is important in the oil and gas industry, where electrical safety is paramount. FRP profiles can provide insulation and prevent electrical conductivity, reducing the risk of accidents and ensuring the safety of personnel and equipment. Overall, FRP pultrusion profiles have proven to be reliable, durable, and cost-effective solutions for various applications in the oil and gas industry. Their corrosion resistance, high strength-to-weight ratio, customization capabilities, and electrical insulation properties make them an attractive choice for this demanding industry.

- Q: Are FRP pultrusion profiles resistant to sulfuric acid?

- FRP (Fiber Reinforced Polymer) pultrusion profiles are generally resistant to sulfuric acid. The corrosion resistance of FRP profiles is one of their key advantages compared to traditional materials like steel or concrete. Sulfuric acid is a highly corrosive substance, but FRP pultrusion profiles can withstand its effects due to the inherent properties of the composite materials used in their construction. The corrosion resistance of FRP profiles is mainly attributed to the resin matrix that encapsulates the reinforcing fibers. Most commonly used resins in pultrusion, such as polyester, vinyl ester, or epoxy, have excellent chemical resistance properties, including resistance to sulfuric acid. However, it is important to note that the resistance of FRP pultrusion profiles to sulfuric acid can vary depending on several factors. The concentration and temperature of the acid, as well as the specific resin formulation used in the profile, can influence the overall resistance. In highly concentrated or elevated temperature environments, it is advisable to consult with the manufacturer or supplier to ensure the specific FRP profile meets the required resistance level. In general, FRP pultrusion profiles offer a high level of resistance to sulfuric acid, making them suitable for various applications in industries where this corrosive substance may be present, such as chemical processing, wastewater treatment, or mining.

- Q: How do FRP pultrusion profiles handle bending and flexing?

- FRP pultrusion profiles are designed to handle bending and flexing exceptionally well due to their inherent structural properties. The combination of reinforcing fibers, such as fiberglass, and a polymer resin matrix in the pultruded profiles results in high strength and stiffness. This allows the profiles to withstand bending forces without any significant deformation or failure. Additionally, the ability of FRP to withstand flexing is attributed to its high fatigue resistance, making it suitable for applications that require repeated bending or flexing movements.

- Q: Can FRP pultrusion profiles be used in wastewater treatment facilities?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in wastewater treatment facilities. FRP pultrusion profiles offer several advantages such as high strength-to-weight ratio, corrosion resistance, and durability, which make them suitable for use in harsh environments like wastewater treatment facilities. In wastewater treatment facilities, there are various applications where FRP pultrusion profiles can be used. These include but are not limited to walkways, handrails, ladders, grating, and structural supports. The corrosion resistance of FRP makes it ideal for use in areas exposed to moisture and chemicals present in wastewater. Furthermore, FRP profiles are lightweight, which simplifies installation and reduces the load on supporting structures. The durability of FRP pultrusion profiles ensures long-term performance, even in aggressive environments. They have a high resistance to chemical attack, UV radiation, and bacterial growth, making them suitable for wastewater treatment applications. Additionally, FRP profiles can be designed to meet specific load requirements and can be easily fabricated to fit various shapes and sizes. Moreover, FRP pultrusion profiles offer excellent electrical insulation properties, which can be advantageous in wastewater treatment facilities where electrical safety is a concern. In summary, FRP pultrusion profiles can be effectively used in wastewater treatment facilities due to their corrosion resistance, durability, lightweight nature, and versatility in design and fabrication. These profiles can provide long-lasting solutions for various applications within these facilities, ensuring operational efficiency and minimizing maintenance requirements.

- Q: What are the mechanical properties of FRP pultrusion profiles?

- FRP (Fiber Reinforced Polymer) pultrusion profiles possess several desirable mechanical properties that make them a popular choice in various industries. Some of the key mechanical properties of FRP pultrusion profiles include: 1. High Strength: FRP pultrusion profiles exhibit exceptional tensile and flexural strength, making them suitable for applications requiring load-bearing capabilities. The reinforcing fibers, such as carbon, glass, or aramid, provide the profiles with superior strength-to-weight ratios compared to traditional materials like steel or aluminum. 2. Lightweight: FRP pultrusion profiles are significantly lighter than metals, resulting in reduced transportation and installation costs. The low weight also makes them easier to handle and manipulate during construction or manufacturing processes. 3. Corrosion Resistance: Unlike metals, FRP pultrusion profiles are inherently corrosion-resistant. They do not rust, corrode, or degrade when exposed to harsh environments, including moisture, chemicals, or UV radiation. This property makes them ideal for applications in marine, chemical, and infrastructure industries. 4. Dimensional Stability: FRP pultrusion profiles offer excellent dimensional stability, meaning they retain their shape and size even under extreme temperature variations. They have minimal thermal expansion and contraction rates, ensuring long-term structural integrity. 5. Electrical Non-Conductivity: FRP profiles are non-conductive and possess excellent electrical insulation properties. This property is crucial in applications where electrical conductivity must be avoided, such as in electrical enclosures or infrastructure near power lines. 6. Design Flexibility: FRP pultrusion profiles can be manufactured in various complex shapes and sizes, allowing for customized designs to meet specific application requirements. They can be easily molded or formed during the manufacturing process, making them adaptable to diverse project needs. 7. Impact Resistance: FRP pultrusion profiles exhibit good impact resistance, absorbing and dispersing energy when subjected to mechanical loads. This property ensures durability and structural integrity, making them suitable for applications prone to impact or dynamic loading, such as construction, transportation, or sporting equipment. Overall, the mechanical properties of FRP pultrusion profiles make them an attractive alternative to traditional materials in a wide range of industries, offering strength, durability, and corrosion resistance while being lightweight and easy to work with.

Send your message to us

FRP Pultrusion Profiles - Best Composites Fiberglass Products FRP Grating with High Quality/Modern Type

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords