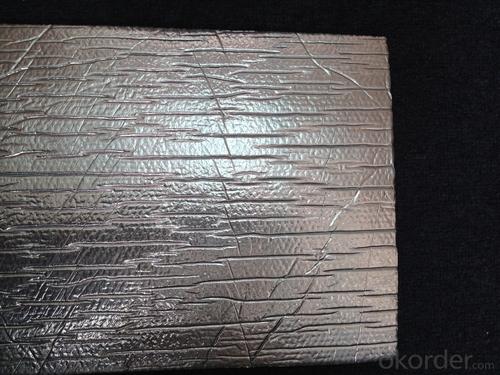

Fiberglass Facing Flexible Ducts Bubble Foil Green Foil Insulation

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Application:

1,Building Thermal Insulation Material

(1),Roof,Underlay,Under Concrete & floor Insulation;

(2),Attic,Crawl Space,Stud Wall ,Metal Frame Building Insulation.

2,Wrapping

(1),Protective coatings of ventilating pipe,HVAC Duct & Pipe;

(2),Shells of air conditioner and water heater.

Feature:

1), Waterproof, heavy duty, clean, light, flexible, non-absorbent surface

2), Fire resistant & antiglare

3), Recyclable, environmentally friendly

4), Effective in extreme temperatures both hot and cold

5), Easily install, cut, stapled, nailed or glued into place

6), Safe to handle with no special clothing or breathing Equipment

Feature:

1), Waterproof, heavy duty, clean, light, flexible, non-absorbent surface

2), Fire resistant & antiglare

3), Recyclable, environmentally friendly

4), Effective in extreme temperatures both hot and cold

5), Easily install, cut, stapled, nailed or glued into place

6), Safe to handle with no special clothing or breathing Equipment

- Q: This question asks for a method to determine if the insulation material in use is made from black fiberglass tissues.

- <p>To determine if your insulation material is made from black fiberglass tissues, you can perform a simple visual inspection. Black fiberglass insulation typically has a dark, almost black color, and is made from fine glass fibers. You can also check for the manufacturer's label or documentation that came with the insulation. If you're still unsure, you can perform a burn test; fiberglass doesn't burn but will melt when exposed to a flame, producing a chemical smell. However, be cautious with this test as it can release harmful fumes. Alternatively, consult with a professional inspector or contractor who can accurately identify the material for you.</p>

- Q: This question asks if there is any difference between black fiberglass tissues that are domestically produced and those that are imported.

- <p>Yes, there can be differences between domestic and imported black fiberglass tissues. These differences may include quality standards, manufacturing processes, material composition, and cost. Domestic products are often more readily available and may be subject to local regulations and standards, while imported products might have different certifications or comply with international standards. Additionally, the cost can vary due to factors like transportation, import duties, and market demand. It's important to consider the specific application and requirements when choosing between domestic and imported black fiberglass tissues.</p>

- Q: What is the specific weight of black fiberglass tissue, and how is it measured?

- <p>The density of black fiberglass tissue, also known as black glass fiber fabric, is typically measured in grams per cubic centimeter (g/cm鲁). It can vary depending on the specific type and weave of the fiberglass, but generally, it ranges from 0.2 to 0.4 g/cm鲁. This density is determined by the weight of the fibers per unit volume. To measure the density, one would weigh a known volume of the fiberglass tissue and divide the mass by the volume to get the density in g/cm鲁.</p>

- Q: What are the standard specifications or criteria that define the quality of black fiberglass tissue?

- <p>Yes, there are standards for the quality of black fiberglass tissue. These standards typically include specifications for tensile strength, elongation, thickness, and other physical properties. The quality is often determined by adherence to industry standards such as ASTM (American Society for Testing and Materials) or ISO (International Organization for Standardization). These standards ensure consistency, reliability, and performance of the fiberglass tissue, which is crucial for applications in various industries such as construction, automotive, and aerospace. Compliance with these standards is verified through testing and certification processes.</p>

- Q: This question asks if there are any health hazards related to the use of black fiberglass tissues in residential or commercial settings.

- <p>There are no specific health risks associated with the use of black fiberglass tissues in homes or businesses. Fiberglass tissues are commonly used for insulation and are made from fine glass fibers. While there are concerns about inhaling fiberglass fibers, these are typically related to occupational exposure in manufacturing or construction settings where large amounts of fibers are present. In normal use, the risk of inhaling harmful amounts of fiberglass is minimal. However, it's always recommended to follow safety guidelines and use personal protective equipment when handling fiberglass materials to minimize any potential exposure.</p>

- Q: Is it possible to utilize black fiberglass tissue in construction?

- <p>Yes, black fiberglass tissue can be used as a building material. It is known for its strength, durability, and resistance to various environmental factors, making it suitable for construction purposes. It is often used in the form of reinforced plastic or composite materials, enhancing the structural integrity of buildings and providing insulation. However, it's important to follow specific guidelines and regulations for its use in construction to ensure safety and effectiveness.</p>

- Q: This question asks if there are any known allergies or sensitivities that people might have when using black fiberglass tissues.

- <p>While black fiberglass tissues are generally considered safe for use, some individuals may experience allergies or sensitivities. These can manifest as skin irritation, respiratory issues, or other allergic reactions. People with a history of allergies to fiberglass or similar materials should exercise caution. It's always recommended to consult a healthcare professional if you suspect an allergy or sensitivity to any product, including black fiberglass tissues.</p>

- Q: This question asks about the distinctions among various types of glass fiber paper, which are materials made from thin strands of glass.

- <p>Different types of glass fiber paper are distinguished by their composition, manufacturing processes, and applications. E-glass is the most common and is used for general purposes due to its good electrical insulation properties. S-glass, known for its high strength, is used in applications requiring mechanical strength, such as in aircraft and sports equipment. C-glass is resistant to chemical corrosion and is used in environments with harsh chemicals. A-glass, or alumino-borosilicate glass, is used for applications requiring high temperature resistance. Lastly, D-glass is designed for low dielectric applications, making it suitable for electronics. Each type has unique properties that make it suitable for specific industries and applications.</p>

- Q: Is it possible to utilize black fiberglass tissue for creating wall paneling?

- <p>Yes, you can use black fiberglass tissue to make wall paneling. Fiberglass is known for its strength, durability, and resistance to moisture and corrosion, making it suitable for wall paneling. It can be molded into various shapes and sizes, and its black color can add a modern aesthetic to your walls. However, it's important to ensure proper installation and adherence to safety guidelines, as fiberglass can cause skin and respiratory irritation if not handled correctly. Always wear protective gear and follow manufacturer's instructions.</p>

- Q: Is it possible to utilize black fiberglass tissue in the manufacturing of furniture?

- <p>Yes, black fiberglass tissue can be used for making furniture. It is a versatile material known for its strength, durability, and resistance to various environmental factors. Fiberglass is often used in outdoor furniture due to its weather-resistant properties. It can be molded into various shapes and is lightweight, making it suitable for a wide range of furniture applications. However, it's important to note that while it can be used, it may not be as common as other materials like wood or metal due to aesthetic and cost considerations.</p>

Send your message to us

Fiberglass Facing Flexible Ducts Bubble Foil Green Foil Insulation

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords