Fiberglass Facing Chopped Strand Mat / Fiberglass Mat Roll Fabric CSM Factory in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Chopped Strand Mat /Fiberglass Mat Roll Fabric CSM Factory in China

Introduction:

Fiberglass chopped strand mat is a non-woven E-or C-glassfiber mat, product manufactured by spreading continuous filament roving of 50mm in length randomly and uniformly in combination with polyester binder in powder form (or other binder in emulsion from). This product is characterized by good combination of resin, easy operation, good wet strength retention, good laminate transparency and low cost. It is suitable for the applications of hand lay-up FRP moldings, such as various sheets and panels, boat hulls, bath tubs, cooling towers, corrosion resistant, vehicles etc.

Function:

Fiberglass chopped strand mat is chopped using the "E" chopped glass and emulsion adhesive bond. It is suitable for hand lay and can enhance the unsaturaed ployester resins.

Technical Data:

| PRODUCT | TYPE | WEIGHT (G/M2) | WIDTH(MM) | ROLL WIEHGT (KG) | MOISTURE CONTENT(%) | BREAKAGE STRENGTH (N) | BINDER CONTENT(%) |

| EMC100 | E/C-GLASS | 100±30 | 200-3300 | 30-90 | < 0.2 | 170 | 8-13 |

| EMC150 | E/C-GLASS | 150±30 | 200-3300 | 30-90 | < 0.2 | 40 | 5-8 |

| EMC225 | E/C-GLASS | 225±30 | 200-3300 | 30-90 | < 0.2 | 60 | 4-7 |

| EMC300 | E/C-GLASS | 300±30 | 200-3300 | 30-90 | < 0.2 | 90 | 3-6 |

| EMC450 | E/C-GLASS | 450±30 | 200-3300 | 30-90 | < 0.2 | 120 | 2-5 |

| EMC600 | E/C-GLASS | 600±30 | 200-3300 | 30-90 | < 0.2 | 150 | 2-5 |

| EMC900 | E/C-GLASS | 900±30 | 200-3300 | 30-90 | < 0.2 | 180 | 2-5 |

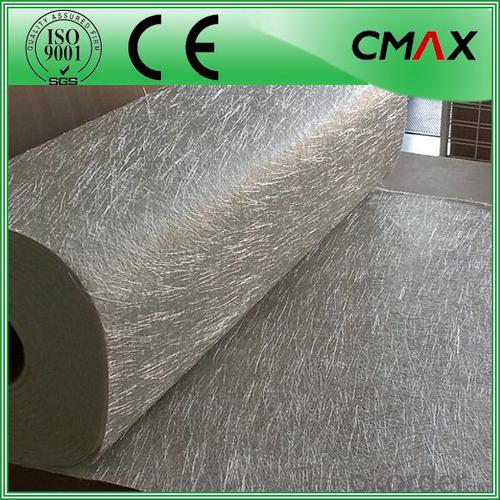

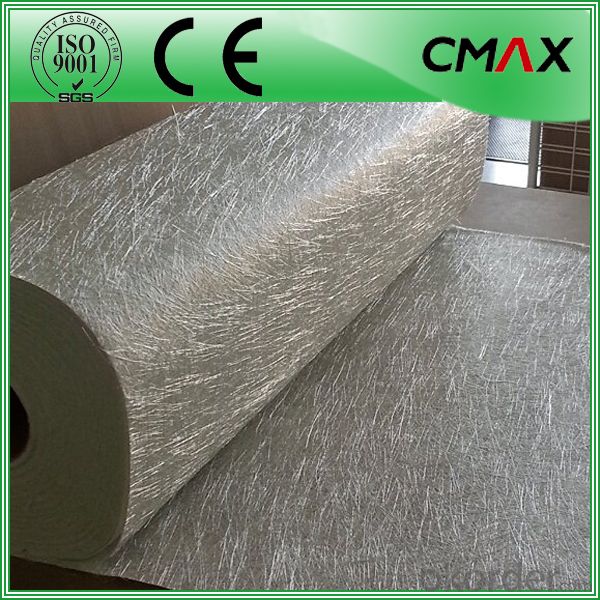

Products Shows:

Certificates:

FAQ:

Is sample available ?

Yes, we provide the free samples, but customers themselves need pay the shipping fee

What's your MOQ?

Our MOQ is one 1*20' full container loading

How do you pack the fiberglass

(1) First, the mat is in roll packed in White PE fIlm.

(2) Then the rolls packed in the carton.

- Q: The user is asking if there are any health risks associated with regular use of black fiberglass tissue.

- <p>Regular use of black fiberglass tissue could potentially be harmful to your health. Fiberglass is made of fine glass fibers that can be inhaled or come into contact with skin, potentially causing irritation or more serious health issues. Prolonged exposure may lead to respiratory problems, skin irritation, and in some cases, more severe conditions like mesothelioma. It's advisable to handle fiberglass with care, using protective gear, and to limit exposure as much as possible. Always refer to the material safety data sheet (MSDS) for specific health and safety information regarding the product you're using.</p>

- Q: This question seeks to understand the impact of black fiberglass tissue on the air quality inside commercial buildings.

- <p>The use of black fiberglass tissue in commercial buildings can affect indoor air quality in various ways. Black fiberglass, when used as insulation, can help reduce energy consumption and maintain a comfortable temperature, but it may also release fibers into the air. These fibers, if inhaled, can cause respiratory issues and are potentially harmful to health. However, modern manufacturing processes have improved to minimize fiber release, and when properly installed and contained, black fiberglass tissue poses minimal risk to indoor air quality. It's crucial to follow safety guidelines and ensure proper ventilation to maintain good air quality.</p>

- Q: How is fiberglass facing used in construction?

- Fiberglass facing is commonly used in construction as a protective layer for insulation materials. It is typically applied to the exterior side of insulation boards or blankets. The facing is made of woven fiberglass fabric or reinforced foil, which adds strength and durability to the insulation. One of the main purposes of fiberglass facing in construction is to act as a vapor barrier. It prevents the passage of moisture through the insulation, reducing the risk of condensation and mold growth. By keeping the insulation dry, it maintains its thermal performance and extends its lifespan. Additionally, fiberglass facing also serves as a radiant barrier. It reflects radiant heat, helping to minimize heat transfer between the environment and the insulation. This property is particularly beneficial in hot climates or when insulating buildings that are exposed to direct sunlight. Moreover, fiberglass facing enhances the mechanical properties of insulation materials. It provides structural support and protection against damage during handling, transportation, and installation. It also improves the fire resistance of the insulation system by acting as a barrier to flames and reducing the spread of fire. In summary, fiberglass facing is a versatile component used in construction to enhance the performance and durability of insulation materials. It acts as a vapor barrier, radiant barrier, and protective layer, ensuring that buildings are well-insulated, energy-efficient, and safe.

- Q: Is it possible to utilize black fiberglass tissue in the manufacturing of automotive components?

- <p>Yes, black fiberglass tissue can be used for automotive parts. It is known for its strength, durability, and resistance to corrosion, making it suitable for various applications in the automotive industry. Fiberglass is often used in the production of body panels, hoods, and other components where weight reduction and structural integrity are important. Its versatility allows for customization in color and texture, including black, which can be beneficial for aesthetic and functional purposes.</p>

- Q: What is the glass fiber needle felt dust filter bag

- Glass fiber needle felt dust filter bag is a high temperature dust bag, is a reasonable structure, better performance of the filter material to glass fiber as raw material

- Q: Is it safe to use black fiberglass tissues in a microwave oven?

- <p>No, you should not use black fiberglass tissues in a microwave oven. Black fiberglass can absorb microwaves and potentially cause sparks or a fire. It is recommended to use microwave-safe materials such as glass, ceramic, or microwave-safe plastic containers when heating food in a microwave. Always check the manufacturer's guidelines for the specific microwave-safe materials and avoid using anything that could be a fire hazard.</p>

- Q: What benefits does black fiberglass offer as an insulation material?

- <p>Black fiberglass insulation has several advantages. It provides excellent thermal insulation, reducing heat transfer and conserving energy. The material is also resistant to moisture and mold, which is crucial for maintaining a healthy indoor environment. Black fiberglass is lightweight, making it easy to handle and install. Additionally, it has high durability and can withstand various environmental conditions, ensuring a long service life. It also offers sound absorption properties, contributing to a quieter living or working space.</p>

- Q: What are the methods to keep black fiberglass tissue clean and free from dirt?

- <p>To prevent black fiberglass tissue from becoming dirty, follow these steps: 1. Regularly clean the surface with a soft brush or cloth to remove dust and debris. 2. Avoid direct exposure to harsh chemicals or substances that can stain or damage the fiberglass. 3. Use a protective cover or shield when working in areas where dirt or debris is likely to accumulate. 4. Apply a protective coating or sealant specifically designed for fiberglass to create a barrier against dirt and stains. 5. Regularly inspect the fiberglass for any signs of damage or wear, and address these issues promptly to prevent further dirt accumulation.</p>

- Q: This question asks for guidance on selecting a dependable supplier for black fiberglass tissues, a material used in various industries.

- <p>To choose a reliable supplier of black fiberglass tissues, consider the following: Check their industry reputation and customer reviews. Ensure they have the necessary certifications and quality control measures in place. Evaluate their product quality by requesting samples. Assess their delivery times and reliability. Consider the supplier's financial stability and history. Look for a supplier that offers good customer service and after-sales support. It's also important to compare prices and negotiate terms that fit your budget and requirements.</p>

- Q: Is it appropriate to use black fiberglass tissue for cleaning windows or mirrors?

- <p>No, it is not recommended to use black fiberglass tissue for cleaning windows or mirrors. Black fiberglass tissue is typically abrasive and can scratch the glass surface, leaving streaks and reducing clarity. Instead, use a microfiber cloth or a soft, lint-free cloth designed for glass cleaning. These materials are gentle on glass and effectively remove dirt and smudges without causing damage.</p>

Send your message to us

Fiberglass Facing Chopped Strand Mat / Fiberglass Mat Roll Fabric CSM Factory in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords