Fiberglass Ceiling Tile - Acoustic Fiberglass Ceiling 20mm Thickness Hot Sale

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

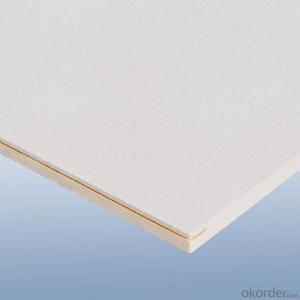

The tile is made by high-density fiberglass with compound decoration wool on the surface and fiberglass wool on the back .The edges are painted. With the characteristics of square in edges and angle,it will be parallel to suspension system after installation.

Product Applications:

The panels are udes widely in schools, offices, music studios, lecture theatres,

multi purpose halls, interview rooms, training areas and cinemas. They meet the

requirements of BB93 of Building Regulations for acoustics in school buildings and

are Class O fire rated hence meeting the Fire Regulations as well.

Product Advantages:

Saves headroom space because exceptional noise absorption effectiveness is achieved by low (30mm) material thickness.

Surfaces can be emulsion painted to any colour without significant loss in noise

absorption. Increase savings due to fast and easy installation.Lightweight and therefore are ideal for adhering to ceilings, which do not have a very high load bearing capabilities.

Meets BB93 standards for school acoustics as well as common areas in flats for Building

Regulations.

Reinforced edges for increased durability.

Main Product Features:

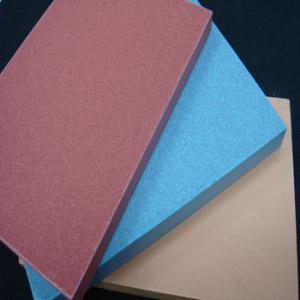

Material: Torrefaction Compounded high density fiberglass wool

Face: Special painting laminated with decorative fiberglass tissue

Color: white, black and others to order

Fire-resistant: class A, non combustible

NRC: 0.9-1.0, excellent sound absorption

Thermal-resistant: >0.4 (m2k/w)

Humidity: Dimensionally stable with RH up to 95% at 40c, no sagging, wrapping, or delaminating

Moisture rete:<1% (JC/T670-2005)

Enviromental impact: Tiles and packing are fully recyclable

Product Specifications:

FAQ:

Qustion1: How can you guarantee the quanlity of your products?

Firstly, our company listed Forture top 500, so we have high reputation in doing business. Secondly, we make our products according to the standards, and if you want to go and see our factories, it is ok and we will welcome you!

Question 2: Where is your factories?

Our factories in different areas of China, such as Shandong Province, Hebei Province, etc.

Images:

- Q: I had a stucco like substance on my bathroom ceiling that was peeling and falling off. I scraped it all off and found a layer of pink paint beneath the stucco that also was peeling in many spots. Underneat the paint is plaster that has some spots. I have an exhaust ceiling fan in the bathroom but don't think it works terribly well. I am considering scraping the remaining paint off then filling in uneven spots and corners with spackling compound then painting over the whole thing again but I am concerned that the spackle will not adhere well in the spotted areas. Does anyone have any recommendations?

- If you have mold in your bathroom dont do the bandaid thing. replace the drywall with blueboard or greenboard. these are both mold resistant.

- Q: Hi, about 2 weeks ago I was in my ex boyfriend's attic (with his permission! lol) and he noticed a crack, which turned into a hole when I slipped and almost fell through into the bedroom! If you lie in bed you can now see right through to the attic; while it could be considered a design feature, my ex isn't keen on it :-) It's not very big, probably only 1.5ft square if that but obviously the plaster is missing, one of the lathes (think that's what they're called; the thin pieces of wood just behind the plaster) is broken in half and poking throught he hole and little bits of the fibreglass indsulation are falling down. My ex told his landlord who said it would cost ?150 to repair the damage, but I'm convinced my ex could do it himself...but how? Any ideas? I have been offered a large piece of plasterboard, could he use this in any way and would he have to enlarge the hole to replace the entire lathe? How does he replaster...etc - help please!

- You only need to replace the lath with anything which will act as a backing for the spack filler which you will need to get from a hardware store or even your local supermarket if your lucky. A suitable replacement will hold your bit of plasterboard, which you have cut to fill the hole as best as possible, and must be able to cope with the environment in the attic, ie not rot. Then fill the crack around the edge with spack filler (white stuff, like plaster, many different types) Then when thet repair has set fill over the plaster board to make it level with the roof, any white spack filler type material. Dry sand and paint to match celing (that is the hard part). Good luck.

- Q: Fireproof fireproof glass fireproof shutter door What is it?

- You can be very intuitive to understand the fire resistance for the decorative parts, fire cut off, fire glass, fire shutter doors have in common, that is played an effective isolation; it is both functional, but also has the role of split space!

- Q: What is the use of halogen powder

- 1, in the chemical industry is an important inorganic raw materials for the production of magnesium carbonate, magnesium hydroxide, magnesium oxide and other magnesium products, but also for the antifreeze and other raw materials. 2, in the metallurgical industry for the production of metal magnesium, liquid chlorine and high purity magnesia and so on. 3, in the building materials industry is the production of light building materials such as fiberglass, decorative panels, sanitary ware, ceilings, floor tiles, magnesium oxide cement, ventilation pipes, anti-theft covers, fire doors and windows, fire board, partition board, production of artificial marble High - rise building materials important raw materials. In the magnesite products can do high-quality magnesium tile, high-quality fire board, magnesium box, magnesium decoration plate, light wall panels, abrasive, stoves, fireworks and other additives. 4, in other areas can do food additives, protein coagulant, snow melting agent, refrigerant, dust, refractories and so on. With the brine (magnesium chloride aqueous solution) point of the tofu than the stone point of the tofu, soft and delicious 5. Metallurgical industry: used to manufacture refractory and pile furnace arm adhesive, and is the manufacture of flux and smelting metal magnesium Of raw materials. 6. Machinery industry: life, with lime soil can be made of mechanical crates, triangular mats and furniture, etc., is "soil material" good material. 7. Transportation industry: for the road ice melting agent, ice fast, less corrosive to the vehicle, higher than the effect of sodium chloride. 8. Medicine: made of magnesium chloride "halogen dry" can be used for medicinal purposes. 9. Agriculture: available for magnesium fertilizer, potassium and magnesium fertilizer and cotton defoliants

- Q: I recently installed speakers in my ceiling for my entertainment center, they sound fine but you can hear them through the floor upstairs. does anyone know what i can do?

- Depends on how involved you want to get and how much you want to spend, however I found cork, (purchased at home depot), worked as a good sound soak material and was easy to glue. Remove the ceiling speaker, glue the cork above it covering as much area as you can reach and reinstall the speaker. Relatively cheap, worked for me.

- Q: Can you play a sound absorbing effect with a grid ceiling?

- Upstairs that is to use fiberglass, this is if it is home improvement, do not choose this, home improvement on the election polyester fiber cotton, the sound-absorbing effect is also good, according to the upstairs that do, polyester fiber sound-absorbing cotton filled 10 cm about there!

- Q: What are the decorative materials?

- Wallpaper, wall tiles, paint, paint, decorative panels, wall carpets, wood plywood, MDF, fire board wire water pipe cement and other hardware

- Q: Write a writing for the future

- Look at some science fiction may help but do not look addicted

- Q: Magnesium chloride crystal structure and detailed solution

- From the magnesium chloride crystals 4.06 g 1.9 g anhydrous magnesium chloride, the mass of the crystal water in the magnesium chloride crystals was 4.06 g-1.9 g = 2.16 g 2.16 ÷ 18 = 0.12 mol The amount of MgCl2 was 0.02 mol. It was found that 0.12 ÷ 0.02 = 6 Magnesium chloride crystals in the crystal water is 6 times the amount of Mgcl2 so n = 6 Chemical formula for Mgcl2 · 6H2O

- Q: What are the active lime use?

- First, the preparation of lime mortar and lime milk coating Lime mortar from lime paste and sand, water mixed together, can be used as the wall, the ceiling of the plaster. Lime milk is made from lime cream and is often used as a paint for interior and ceiling. Second, the preparation of lime and triad soil Lime: lime + clay. Triad: lime + clay + sand, stone or slag and other fillers. Can be widely used as the basis of the building, the road or the ground cushion. Third, the production of carbonized lime board The calcined lime board is a lightweight sheet made of ground lime, fibrous filler (such as glass fiber) or lightweight aggregate (such as slag), and then made by artificial carbonization. It is suitable for non-load bearing inner wall panel , Ceiling and so on. Fourth, the production of silicate products Grinding of lime or lime powder and sand or granulated blast furnace slag, slag, fly ash and other siliceous materials by ingredients, mixing, molding, and then pressure or high pressure steam curing, can be made of dense or porous silicate products The Such as lime sand bricks, fly ash bricks and blocks, aerated concrete blocks and so on. Fifth, the preparation of clinker-free cement Will have a certain activity of the material (such as granulated blast furnace slag, fly ash, coal gangue ash and other industrial waste), according to the appropriate proportion of lime with the common grinding, can be obtained with hydraulic cementing material, that is No clinker cement.

Send your message to us

Fiberglass Ceiling Tile - Acoustic Fiberglass Ceiling 20mm Thickness Hot Sale

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords