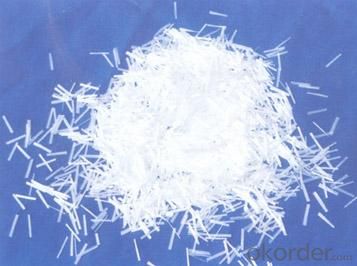

Fiberglass Mat Tissue Chopped Strands for Thermoplastic

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 kg

- Supply Capability:

- 1000000Kg Per Month kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Introduction

Chopped Stands for Thermoplastic are based on silane coupling agent and special sizing formulation, compatible with PA,PBT/PET, PP, AS/ABS, PC, PPS/PPO,POM, LCP;

2.Product Features

Extremely low resin demand, delivering low viscosity to BMC paste

High impact strength; High LOI rate

High strand stiffness; Compatible with rubber

3.Product Specifications

Property | Fibre diameter | Moisture Content | Size Content | Chop |

(%) | (%) | (%) | (%) | |

Mathods | IS01888 | ISO3344 | ISO1887 | |

3mm | ±10 | ≤3.0 | 0.1±0.05 | 98 |

6mm | ||||

9mm | ||||

12mm |

Special specification can be produce according to customer requirements.

4.FAQ

Packaging:

Each bag can be taken (15-25kgs). Could also take a big container bag.

Storage:

Unless otherwise specified, It should be stored in a dry, cool and rain-proof area. It is recommended that the room temperature and humidity should be always maintained at 15℃~35℃ and 35%~65% respectively.

- Q: Can fiberglass mat tissue be used for windbreak panels?

- Yes, fiberglass mat tissue can be used for windbreak panels. It is a lightweight and durable material that can provide effective protection against wind and other environmental elements.

- Q: Can fiberglass mat tissue be used for HVAC insulation?

- No, fiberglass mat tissue is not typically used for HVAC insulation. HVAC insulation usually requires materials that are specifically designed to have high thermal resistance and to prevent the transfer of heat or cold air. Fiberglass mat tissue is commonly used as a reinforcement material in the fabrication of composite materials, such as fiberglass panels or structures, rather than as insulation. Insulation materials for HVAC systems are typically made from materials like fiberglass insulation boards, foam insulation, or mineral wool, which have better thermal resistance properties and are specifically designed for HVAC applications.

- Q: Is fiberglass mat tissue resistant to mold growth?

- Yes, fiberglass mat tissue is resistant to mold growth. Fiberglass is made from glass fibers that are tightly woven together, creating a material that is highly resistant to moisture and mold. Additionally, fiberglass is non-porous, meaning it does not absorb water, which further inhibits the growth of mold. This makes fiberglass mat tissue an ideal choice for applications where mold resistance is important, such as in insulation, wallboards, and other construction materials.

- Q: Can fiberglass mat tissue be used for insulation in cold environments?

- Yes, fiberglass mat tissue can be used for insulation in cold environments. Fiberglass is a common material used for insulation due to its excellent thermal properties. It has a low thermal conductivity, meaning it can effectively resist the transfer of heat, thus providing insulation in cold environments. Fiberglass mat tissue is specifically designed to provide thermal insulation and is commonly used in applications such as walls, roofs, and floors to prevent heat loss and maintain a comfortable temperature indoors. Additionally, fiberglass is resistant to moisture and does not easily degrade or lose its insulating properties in cold and damp conditions, making it a suitable choice for insulation in cold environments.

- Q: Can fiberglass mat tissue be used for making lightweight ceilings?

- Yes, fiberglass mat tissue can be used for making lightweight ceilings. Fiberglass mat tissue is a thin and lightweight material made from fiberglass strands that are bonded together with a binder. It is commonly used in construction and building applications due to its excellent strength-to-weight ratio. When used for making lightweight ceilings, fiberglass mat tissue can provide several advantages. Firstly, it is lightweight, which makes it easier to handle and install. This can save time and effort during construction or renovation projects. Additionally, fiberglass mat tissue is also known for its high tensile strength and durability, making it a suitable choice for ceilings that need to withstand various loads and stresses. Furthermore, fiberglass mat tissue has good thermal insulation properties, which can help in maintaining a comfortable indoor environment. It can also offer sound insulation benefits, reducing noise transmission between different spaces or floors. Moreover, fiberglass mat tissue is resistant to moisture, mold, and mildew, which makes it suitable for areas with high humidity or moisture concerns such as bathrooms or kitchens. It is also non-combustible, providing an added level of fire resistance to the ceiling structure. In conclusion, fiberglass mat tissue can indeed be used for making lightweight ceilings. Its lightweight nature, strength, durability, thermal and sound insulation properties, as well as resistance to moisture and fire, make it a suitable choice for various ceiling applications.

- Q: Can fiberglass mat tissue be used for making insulation jackets?

- Yes, fiberglass mat tissue can be used for making insulation jackets. Fiberglass mat tissue is a versatile material that is commonly used in various insulation applications due to its excellent thermal insulation properties. It is lightweight, flexible, and provides effective insulation against heat transfer. When used in insulation jackets, fiberglass mat tissue can help to retain heat and prevent heat loss, making it an ideal choice for applications where thermal insulation is required. Additionally, fiberglass mat tissue is also fire-resistant, which further enhances its suitability for insulation jackets.

- Q: Can fiberglass mat tissue be used in wet environments?

- Indeed, wet environments can indeed accommodate the utilization of fiberglass mat tissue. This specialized material has been ingeniously engineered to possess an inherent resistance to moisture, thereby enabling it to endure prolonged exposure to water. Consequently, this remarkable attribute renders it highly suitable for deployment in various sectors, most notably construction, marine, and automotive industries. These particular domains frequently necessitate the deployment of components or structures that inevitably encounter water, humidity, or moisture. The material's unparalleled resistance to water impeccably guarantees the preservation of its structural robustness and ensures that it remains impervious to degradation or any diminishment in its performance properties even when confronted with damp conditions.

- Q: Is fiberglass mat tissue suitable for insulation in residential buildings?

- Residential buildings find fiberglass mat tissue to be a suitable option for insulation. This insulation material, made from glass fibers, is commonly used because of its exceptional thermal properties. With a high R-value, it effectively reduces heat transfer, keeping interiors warm in winter and cool in summer. In addition to its thermal efficiency, fiberglass mat tissue is renowned for its durability and long lifespan, making it a reliable choice. It resists moisture, mold, and pests, ensuring a healthy and comfortable living environment. Moreover, its lightweight nature and easy installation process make it efficient and cost-effective for insulation purposes. Moreover, fiberglass mat tissue possesses the crucial feature of being fire-resistant, which is highly desirable for residential buildings. It acts as a protective barrier, preventing the spread of fire and safeguarding occupants and property from potential hazards. Overall, fiberglass mat tissue is a popular and appropriate option for residential insulation due to its thermal efficiency, durability, fire resistance, and easy installation.

- Q: What are the different reinforcement patterns available for fiberglass mat tissue?

- Fiberglass mat tissue offers various reinforcement patterns, each with its unique benefits and characteristics. 1. Random Chopped Strand Mat (CSM) is widely utilized and consists of randomly chopped fiberglass strands held together with a binder. It boasts good strength and stiffness properties, making it suitable for a wide range of applications. 2. Continuous Strand Mat (CSM) features evenly distributed continuous fiberglass strands bound together with a binder. It offers enhanced strength and stiffness compared to random chopped strand mat, making it perfect for high-performance applications. 3. Woven Roving comprises interwoven bundles of fiberglass yarns and provides exceptional strength and impact resistance. It is ideal for applications that require high load-bearing capabilities. 4. Multiaxial Fabrics consist of multiple layers of fiberglass fibers oriented in different directions, offering balanced strength properties in multiple directions. This makes it perfect for applications that require isotropic properties. 5. Stitch-Bonded Fabrics are created by mechanically stitching together layers of fiberglass fibers. They offer good drapability and conformability, making them suitable for complex shapes or curved surfaces. 6. Knitted Fabrics are made by interlocking loops of fiberglass yarns, providing excellent flexibility and ease of handling. They are suitable for applications that require conformability and flexibility. Each reinforcement pattern possesses its own advantages and is utilized in various applications based on specific requirements such as strength, stiffness, impact resistance, flexibility, or conformability. It is crucial to select the appropriate reinforcement pattern based on desired end-use properties and the manufacturing process.

- Q: Can fiberglass mat tissue be used for insulation in research laboratories?

- Yes, fiberglass mat tissue can be used for insulation in research laboratories. It is a common material choice due to its excellent thermal insulation properties and fire resistance. Additionally, fiberglass mat tissue is lightweight, durable, and easy to install, making it suitable for various insulation applications in laboratories.

Send your message to us

Fiberglass Mat Tissue Chopped Strands for Thermoplastic

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 kg

- Supply Capability:

- 1000000Kg Per Month kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords