Fiber cement sandwich board

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

| Performance Parameters: | |||||

| ltem | Unit | Thickness 125mm | Thickness 100mm | Thickness 75mm | Thickness 50mm |

| Standard of dry shrinkage value | mm/m | ≤0.6 | ≤0.52 | ≤0.49 | ≤0.46 |

| Sound insulation volume in the air | dB | ≥50 | ≥48 | ≥48 | ≥40 |

| Shockproof strength | The time of no through crack | 10 Times | 10 Times | 10 Times | 5 Times |

| Anti-bending collapsing strength | The multlple of the board's self-weight(Put pressure) | ≥6.0 | ≥6.0 | ≥6.0 | ≥6.0 |

| Hanging force | N | 1000 | 1000 | 1000 | 800 |

| Fire-resistant limit | H | 5 | 4 | 3 | 2 |

| Combustiblllty performance | Level | GB8624 A1 Level non-combustible | |||

| Coefficient of heat conductivily(W/MK) | 0.021 | ||||

| The Anti-returns(24h) | No drop of water and no damp | ||||

| Gas proof and anti-moth function | lnorganic substances have insect-resistant,gas proof and anti-moth performance | ||||

| Water permeability resistant | waterproof | ||||

| Moisture(%) | ≤9 | ||||

| Standard Specification: | |||||

| Width:610mm Length:3050/2440mm Thickness: 50/75/100/125mm | |||||

| Application Recommended: | |||||

| Widely used in non-load-bearing interior and exterior walls of buildings, commercial buildings, office partition wall,and need water proof, noise proof and moisture proof requirements place. | |||||

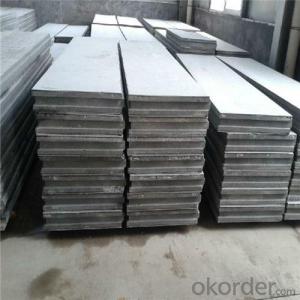

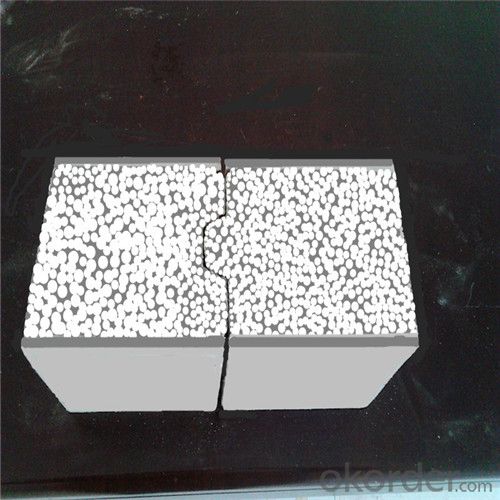

Fiber cemnt sandwich panel, light weight concrete sandwich panel

1. Composition:

Core materials: cement, EPS, and fly ash core

Surface materials: fiber reinforced calcium silicone board or cement calcium silicone board

2. Specification: (L*W*T)

1500-3000mm X 610mm X (50, 75, 100, 120,150,180mm)

fiber cement board on both sides: 5mm, 6mm, 8mm

3. Usage:

Interior and exterior partition on steel or concrete structure building,

For new construction, additions or renovations.

4. Advantages:

Energy-saving

Light weight

Sound insulation

Environmental protection

Most area-saving

Most waterproof and dampproff

Most fire-proof

Most sound-insulation

Best hanging force

Most anti-seismic and impact resistance

Largest span and height thin webbed wall

Most civilized, environmental, high efficiency construction.

- Q: How to calculate the amount of steel wool sandwich panel

- Directly by area, pay attention to the manufacturer's production specifications may affect the consumption. General plate to take both sides recognized the price into the settlement.

- Q: Is polystyrene sandwich board flammable?

- In general, the benzene board is flammable, but there is a flame retardant type, is the type of self-extinguishing. Usually used as building materials. The other is basically flammable.

- Q: 100 thick 960 color steel sandwich board how much money one meter? What is the bulk density?

- This is not necessarily normal 8 kg, 10 kg

- Q: Want to buy sandwich panels, where there are good manufacturers?

- OKorder Teng Wei color steel, a good manufacturer, Teng Wei Caigang, color steel industry in the fighter

- Q: Rock wool sandwich panel price rock wool sandwich board how much money a square meter

- This depends on the weight of rock wool, as well as color steel kind. If you need, we plant production. This answer is provided by Hebei Chengxin chemical building materials, if satisfied please adopt.

- Q: 100 thick roof color steel foam sandwich panels how to calculate the weight

- You calculate 1 square meters wide inside and outside the two thin steel plate added to the foam core weight, the number multiplied by 10, is the bulk density, its unit is ㎏ / m?. Or, weigh each block to remove each area, then multiplied by 10, is the bulk density.

- Q: Color steel sandwich panels

- It depends on what grade you choose the color plate, including the surrounding environment and many other effects. The last one or two years on the rust rotten, the current market should be the best Baosteel color plate, but the price is more expensive, to the color steel sandwich board than the same level of other small manufacturers to 10 to 20 yuan Per meter, under normal circumstances, if you want to live for a long time, I suggest you do not use materials than low 0.5mm thick color plate, the general manufacturers can also use the color plate 8-15 years, if the board is too thin, then not Good to say, the thinner the color plate, the faster the corrosion, if the use of Baosteel's color plate, with more than 15 years should not be a problem. Due to price factors, the general small manufacturers do not have Baosteel color plate.

- Q: Will the rock wool sandwich board which manufacturers better?

- I know, you can consider Zhejiang Bo Ya building materials, production Yanmian sandwich panels, all kinds of sandwich panels,

- Q: Sandwich panel sandwich board classification

- According to the functional requirements of Party A or plant to choose the type of roof sandwich panels, such as you want to set fire, then generally use rock wool; insulation, then with the composite board, as is the general insulation or important insulation (for cold storage) According to his weight. As for the upper and lower board general Party has a request, if the party did not ask, it is like a routine

- Q: With a foam sandwich board made a 72 flat house, the cheapest how much money

- It depends on how high your house, the color plate is calculated by the board area, calculate the material about 90 or so per square

Send your message to us

Fiber cement sandwich board

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords