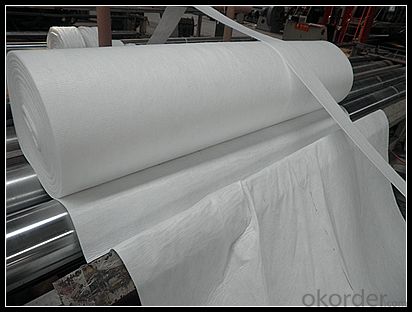

FHWA Certified Short Non-Woven Geotextile Road Building Constructive Felt Fabric with Cheap Price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

CNBM Geotextile acts as a separator between two layers of soil that have different particle size distributions. CNBM Geotextiles are used to prevent road base materials from penetrating into soft underlying sub grade soils, thus maintaining design thickness and roadway integrity. Separators also help to prevent fine-grained sub grade soils from being pumped into permeable granular road bases.

Filtration

CNBM Geotextile acts similar to a sand filter by allowing water to move through the soil while retaining all upstream soil particles. CNBM Geotextiles are used to prevent soils from migrating into drainage aggregate or pipes while maintaining flow through the system. CNBM Geotextiles are also used below rip rap and other armour materials in coastal and river bank protection systems to prevent soil erosion.

filtration

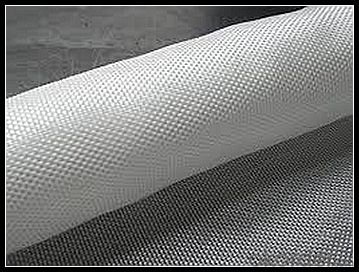

Reinforcement

CNBM Geotextile acts as a reinforcement element within a soil mass or in combination with the soil to produce a composite that has improved strength and deformation properties over the unreinforced soil. CNBM Geotextiles are used to add tensile strength to a soil mass in order to create vertical or near vertical reinforced soil walls and steep slopes.

Reinforcement

Separate: Geotextile when used as a separation layer prevents two different fill materials such as aggregate and soil from combining. When used correctly the geotextile will increase the life span of the civil project, allowing the two separate layers to perform as designed for longer.

Protection: Geotextile when used as a protection layer acts as a cushioning barrier between the geosynthetic lining system and other layers of the dam or landfill cell. Generally the larger mass rolls of geotextile provide the best cushioning protection. As a protection barrier it helps prevent puncturing and leaks from external forces coming into contact with the liner.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

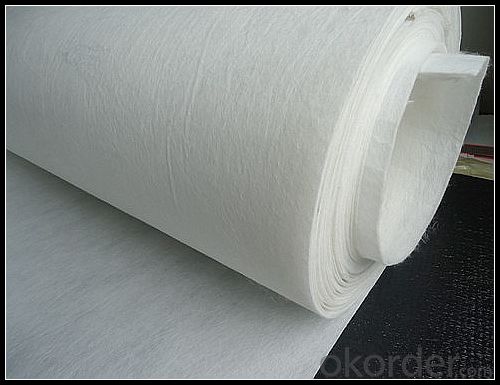

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

- Q: Are geotextiles commonly used in civil engineering projects?

- Yes, geotextiles are commonly used in civil engineering projects. They are versatile materials that are used for various purposes such as erosion control, soil stabilization, filtration, and drainage. Geotextiles provide reinforcement and protection to structures, enhance the performance of soils, and help in the construction and maintenance of infrastructure projects like roads, railways, embankments, and retaining walls.

- Q: Performance and Application of Impervious Geotextile

- Anti-seepage geotextile has excellent water permeability, filterability, durability, can be widely used in railways, highways, sports museum, dams, hydraulic construction, then hole, coastal beach, reclamation, environmental protection and other projects. Mainly staple acupuncture non-woven geotextile and split film woven geotextile. Anti-seepage geotextile function: 1. The use of geotextiles good permeability and water permeability, so that water through, so as to effectively remove the loss of sand. 2. Geotextile has a good water conductivity, it can form a drainage channel within the soil, the soil structure of the excess liquid and gas efflux. 3. Using geotextile to enhance the soil tensile strength and resistance to deformation, enhance the stability of the building structure to improve the quality of soil. 4. Effective focus will be concentrated diffusion, transmission or decomposition, to prevent soil damage by external forces. 5. to prevent the upper and lower gravel, soil and concrete mixed between. 6. Mesh is not easy to plug - due to the formation of amorphous fibrous tissue structure and strain and mobility. 7. High permeability - under the pressure of soil water, can still maintain a good permeability 8. Corrosion resistance - to polypropylene or polyester and other chemical fiber as raw materials, acid and alkali, no corrosion, no moth, antioxidant. 9. Construction is simple - light weight, easy to use, simple construction. Anti-seepage geotextile characteristics High anti-puncture strength, large coefficient of resistance to aging performance, to adapt to the environmental temperature range Excellent excellent anti-drainage performance for water conservancy, chemical, construction, transportation, subway, tunnel, garbage disposal and other projects

- Q: How do geotextiles contribute to soil filtration?

- Geotextiles contribute to soil filtration by acting as a barrier that allows water to pass through while retaining soil particles. They enhance the filtration process by preventing the migration of fine particles and protecting the underlying soil from erosion.

- Q: This is a large sample of gravel anti-filter how this project count

- Visual inspection of the slope of the distance from the clay layer is equal to the thickness of the gravel layer, that is 200mm, so even if it came out scattered Simple function. Also, I used a simple method is to draw in CAD, fill, measure the area, area by length, the volume came out

- Q: Can geotextiles be used in golf course construction?

- Yes, geotextiles can be used in golf course construction. They are often used to provide erosion control, soil stabilization, and drainage solutions in areas such as golf course bunkers, greens, fairways, and tee boxes. Geotextiles can help prevent soil erosion, improve water drainage, and enhance the overall durability and maintenance of golf course surfaces.

- Q: How do geotextiles help with sediment filtration in stormwater ponds?

- Geotextiles help with sediment filtration in stormwater ponds by acting as a barrier to prevent sediment from entering the water. They are placed at the bottom of the pond or along the sides to trap sediment particles while allowing water to flow through. This helps in reducing the amount of sediment that settles in the pond, ensuring cleaner water and improving the overall efficiency of the stormwater management system.

- Q: How to judge the geotextile test results are reliable

- Determine whether the tensile test results of the material are reliable, depending on whether the tensile process of the material to be tested during the test has reached the state required by this detection method. As a tensile test, to test the tensile strength and elongation of the material under specified conditions. Stretching process, the material to be tested to be uniform force, the test machine fixture holding the sample to be solid, the sample does not produce slip nor be caught damage. This is the test process of the requirements of the test machine fixture and the installation of the sample requirements, only to meet this requirement and other requirements, the test results may be accurate. Geotechnical composite materials - Geosynthetics - Staple acupuncture non - woven geotextiles GB / T-1998 Geosynthetics - Filament spunbonded acupuncture non - woven geotextiles GB / T - 1998 Geosynthetics Geosynthetics - Geosynthetics - Geosynthetics - Geosynthetics - Geosynthetics - Geosynthetics - Geosynthetic materials GB / T - 1998 Geosynthetics - Geological synthetic materials Polyvinyl chloride geomembrane GB / T-1999 Geosynthetics Plastic geogrid GB / T-1999 Geosynthetics Plastic flat wire braided geotextiles GB / T-2002 Geosynthetics Plastics 3D geogrids GB / T-2002 geosynthetics / outer composite geotextile

- Q: Can geotextiles be used in pond and lake liners?

- Yes, geotextiles can be used in pond and lake liners. They are often used as a protective layer to prevent punctures and abrasions in the liner material, and to enhance the overall stability and durability of the liner system. Geotextiles can also improve filtration and drainage properties, helping to maintain the quality and functionality of the water body.

- Q: Are geotextiles resistant to puncture?

- Yes, geotextiles are designed to be resistant to puncture. They are typically made from durable materials such as synthetic fibers or woven fabrics that offer excellent puncture resistance. This helps ensure their effectiveness in various applications where protection against punctures, such as in soil stabilization or erosion control, is crucial.

- Q: What is geotextile, what role

- Geotextile is a new type of building materials, raw materials are polyester, acrylic, nylon and other polymer polymer synthetic fiber. In accordance with the manufacturing method is divided into: there are two types of geotextile and non-woven geotextile. Geotextile with anti-seepage, anti-filtration, drainage, isolation, reinforcement, protection, sealing and other functions, it with the conventional masonry and concrete material seepage effect compared to a low investment, simple construction process, short duration Infiltration effect is good, the channel effective use of high coefficient. Water conservancy engineering dams and slope protection filter, channel isolation, seepage control; road, railway, airport runway foundation isolation, filter, drainage, slope, retaining wall and road reinforcement, drainage; , Geotextile has been widely used in the field of infrastructure construction, and has been gradually applied in the field of infrastructure construction, and the use of geotextile In a wider area.

Send your message to us

FHWA Certified Short Non-Woven Geotextile Road Building Constructive Felt Fabric with Cheap Price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords