Ferro Silicon Origin In Henan Province CNBM China Fortune 500

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Usage

Ferro silicon is widely used in the steel making,iron casting ,low-carbon ferroalloy producing:

1 In the steel making field,Ferro silicon is used as deoxidizer and alloying agent to precipit and diffusedeoxidation.Adding a certain amount silicon of fe-si to the steel can obviously improve the strength ,hardness ,elasticity and permeability of steel.

2 In the iron casting,it is used as ball mile agent and alloying agent especially in the nodular iron casting, Adding ferrosilicon to cast iron ,it can prevent the formation of carbide and promote the precipitation of graphite and the nodulizing.then the mechanical capacity can be the same of steel's.

3 High-silicon ferrosilicon can be used for the production of the low-carbon reductant in ferro alloy industry.

4 In addition ,ferro silicon powder can be used as a suspended phase in the mineral processing industry and coatings for welding electrodes in the electrode manufactruing.

Application

Used as deoxidants and desulfurizing agents, and could purity the molten steel, etc. The size includes:0-3mm, 3-25mm,10-50mm, etc.

Packaging & Delivery

Packing Details: In 1 MT Jumbo Bags

Delivery Detai | Within 30 days after received the deposite |

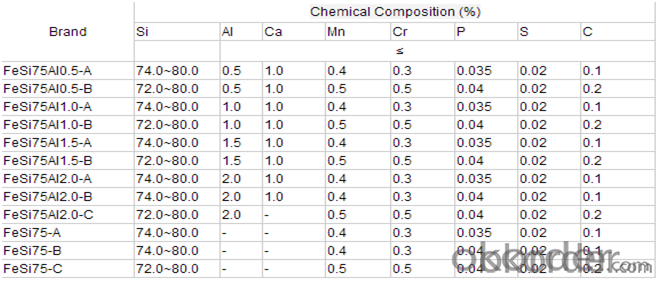

Specification

- Q: Hard alloy is tungsten?

- Tungsten, titanium, tantalum (niobium) carbidesIs the main component of tungsten carbide, titanium carbide, tantalum carbide (or niobium carbide) and cobalt. This kind of hard alloy is also called universal cemented carbide or universal hard alloy.

- Q: I'm going to sell carbide cutters. Which industry do you want to sell?

- Don't know whether you go to Suzhou haokai steel metal material limited company to see through

- Q: What are the three types of commonly used cemented carbides?

- As the mass fraction of cobalt increases, the hardness and wear resistance decrease, and the flexural strength and toughness increase.M class (equivalent to our YW class), cemented carbide is based on WC, TiC, Co, and then added TaC (or NbC). After the addition of TaC (or NbC), the comprehensive properties of cemented carbide were improved. This kind of cemented carbide can process both cast iron and non-ferrous metals, and also can process steel materials. It can also process difficult materials such as high temperature alloy and stainless steel. Commonly used brands are YW1 and YW2.

- Q: What kind of material is the alloy drill bit?

- Alloy bit generally refers to the hard alloy bit, divided into integral, welded, indexable inserts and replaceable type.The main components of cemented carbide are tungsten carbide, cobalt, etc., the hardness is relatively high, generally above HRC90 degrees, and it is suitable for batch processing and hard processing!

- Q: I am 985 material girls graduated, looking for a job, want to know about

- As a Zhuzhou person, I recommend the Zhuzhou cemented carbide to you, not only because the units are good, but also the city of Zhuzhou is very good. You must have lived here since you worked here. House prices are much lower than in many second tier cities. The standard of living is also good, the large supermarkets are complete, Fantawild is the Southwest's largest amusement park.... Wait

- Q: Is carbide resistant to alkali?

- That theory is divorced from practice is the greatest misfortune

- Q: What is the consciousness of YT in YT cemented carbide?

- YT carbide hard alloy has relatively high hardness, but poor toughness, poor impact resistance. It is suitable for processing plastic material used to machining without quenching medium and low carbon steel, alloy steel and so on.

- Q: The use of wire cutting cut a knife head rest wear found with magnetic iron absorption, cutting.

- I use a magnet to suck the used MITSUBISHI VI15TF block and have some magnetism

- Q: Import all carbide drill bit, mainly those brands

- Good (maford), Kenna, Thomas, di tex, Sandvik, guhring general in the domestic production, the performance of discount.Recommended by the earth, good performance, high cost of some.The materials they use for cutting tools are generally not for sale. You must understand that.What does it mean when you don't understand it?

- Q: Where can I use cemented carbide?

- Cemented carbide is a kind of alloy material made by powder metallurgy process of hard metal and bonding metal of refractory metal.Hard alloy with high hardness, strength and toughness, good wear resistance, heat resistance, corrosion resistance and a series of excellent performance, especially high hardness and wear resistance of it, even at a temperature of 500 DEG C also remained unchanged, at 1000 degrees C still have high hardness.Hard alloy is widely used as a tool material, such as turning, milling, planing, drilling, boring, used for cutting cast iron, non-ferrous metals, plastics, chemical fiber, graphite, glass, stone and steel, can also be used for cutting steel, stainless steel, high manganese steel, tool steel and other hard processing materials. Can be used to make drilling tools, mining tools, drilling tools, measurement tools, wear parts, metal grinder, cylinder liner, precision bearings, nozzle, metal mold (such as wire drawing dies, molds, mold, nut bolt fasteners and various molds, carbide goodnature can gradually replace the steel mold before).Carbide mainly YT, YN, YW and YG series, according to the different properties applied to different fields.

Send your message to us

Ferro Silicon Origin In Henan Province CNBM China Fortune 500

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords