Ferro Silicon Popular In Iron Casting CNBM Fortune500

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

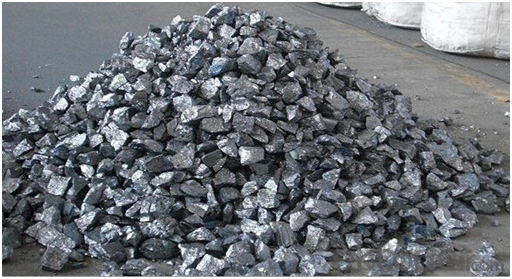

Ferro Silicon Description

Ferro Silicon is a kind of ferroalloy which is composed of ferrum and silicon. Ferro Silicon uses coke, quartz

(or silica) as raw materials and is made by electric furnace. Because silicon and oxygen are easily compound

into SiO2, the ferrosilicon is often used as deoxidizer in steelmaking.

Ferro Silicon Application

1. Fesi 75% is often used as deoxidizer in steel- making.

2. Ferrosilicon also can be used as alloy elements join agent, which is widely used in low alloy steel, non-ferrous metal, bearing steel, heat-resistant steels and electrician silicon-steel.

3. It can be used as a reductant in ferroalloy production and chemical industry.

4. In iron industry it can be used as inoculant and nodulizer.

Specification

Brand | Chemical Composition (%) | ||||||||||

Si | Al | Ca | P | S | C | Fe | |||||

<= | |||||||||||

FeSi75-A | 74.0-80.0 | 1.5 | 1 | 0.035 | 0.02 | 0.2 | Balance | ||||

FeSi75-B | 72.0-80.0 | 1.5 | 1 | 0.04 | 0.02 | 0.2 | Balance | ||||

FeSi72 | 72 | 1.5 | 1 | 0.04 | 0.02 | 0.2 | Balance | ||||

FeSi70 | 70 | 1.5 | 1 | 0.04 | 0.02 | 0.2 | Balance | ||||

FeSi65 | 65.0-72.0 | 2 | 1 | 0.04 | 0.02 | 0.2 | Balance | ||||

FeSi45 | 40.0-47.0 | 2 | 2 | 0.04 | 0.02 | 0.2 | Balance | ||||

Packaging & Shipping

1. Plastic bag(antiproof) +Iron barrel, all adjustable to customer's specific demands.

2. Shipment within 3 working days after production.

Ferro Silicon Size

0-3mm,3-10mm,10-100mm or as the customers’ requirements

Packing

25Kg/bag, 1MT/bag or as your requirements.

Picture

- Q: What type of carbide for punching dies? Better. Where can I buy it?

- Stamping die is divided into cold stamping and hot stamping, need more different uses to choose different characteristics of carbide brand, you can understandZhuzhou same cemented carbide.

- Q: Carbon steel valves in Baidu LibraryThe temperature can reach 425 degrees, is not without welding carbide seal, who has no detailed material ah?,

- This 425 DEG C is the limit temperature of ASTM A216: -30 DEG C - +425 DEG CBut if the sealing surface of rice now is PTFE, it can be as high as +80 degrees centigrade. If the PTFE material is good, it can reach +150 centigradeTherefore, the body material is carbon steel, only that the valve body of the temperature range of this materialLook at the inside of the valve,For example, cryogenic carbon steel in LCB, ASTM, A325 can reach -46 degrees --+340 degrees centigradeHowever, if the sealing surface of your body is the sealing surface of plain carbon steel, the temperature range of this carbon steel valve is only the temperature range of the ordinary carbon steelIf you say that now is the carbon steel valves used in the sealing surface of the safety valve, you must need welding hard alloy (STL or D series, etc.) should have strong hardness of hard alloy after treatment, impact resistance.Depends on your flow channel medium, if it is high temperature, it is best to use 316, and so onThe use of valves is a combination of considerations

- Q: What are the grinding carbide wheels?

- Diamond grinding wheel, carborundum wheel. Only welded blades use carborundum wheels, and generally fine grinding blades use diamond grinding wheels.

- Q: What kind of cemented carbide is the most wearable?

- Carbide wear is due to the grain size and the cobalt content determines the finer granularity of cobalt content is lower, the higher hardness and lower hardness should be mentioned is the selection of wear-resistant hard alloy not only the hardness to see the use of general cutting hard alloy material with YW2 a relatively high hardness but if the working conditions impact operations more frequently if it should take into account its toughness but the toughness and hardness is conflicting under such circumstances can choose the class YG fine grain alloy

- Q: I am 985 material girls graduated, looking for a job, want to know about

- As a Zhuzhou person, I recommend the Zhuzhou cemented carbide to you, not only because the units are good, but also the city of Zhuzhou is very good. You must have lived here since you worked here. House prices are much lower than in many second tier cities. The standard of living is also good, the large supermarkets are complete, Fantawild is the Southwest's largest amusement park.... Wait

- Q: What is the difference between the raw and recycled materials of cemented carbides? The more specific, the better

- Raw raw materials are raw materials, recycled materials have been used, and then recycled and re produced, raw materials than recycled materials used, and more pure materials.

- Q: What are the advantages of carbide V-CUT knives and diamond V-CUT knives?

- Precision machining, high finish, sharp blade, machining V groove surface smoothness, no burr burr, greatly improve product quality.Polycrystalline diamond V-CUT knife is now used more and more, and its advantages are: hardness is higher than hard alloy, longer service life, especially in the CNC V-CUT Slitter, the use of good results.

- Q: What type of emery grinding machine is 3000/min for grinding carbide turning tools (e.g., YG8.YS8.YT15.YW1, etc.)?

- Diamond grinding wheel, green carborundum wheel can be used. Two, choose one, or choose the former good. Diamond grinding wheel has the advantages of less wear, long life, high productivity and good processing quality, that is, the price is a little more expensive.

- Q: What are the common kinds of cemented carbides?

- Cemented carbide is a hard particle of refractory metals (tungsten, tantalum, titanium, molybdenum, etc.) that is mixed with one or more iron elements (cobalt, nickel, or iron), pressed and molded, and then sintered. Types and properties of cemented carbides: (1) classification and grade of cemented carbides. Tungsten carbide cobalt carbide is mainly composed of tungsten carbide (WC) and binder cobalt (Co). The brand is from "YG" ("hard cobalt" Pinyin prefix) composition and percentage of average amount of cobalt. For example, YG8 is a tungsten cobalt carbide that represents an average WCo = 8% and the remainder is tungsten carbide. Tungsten carbide cobalt carbide is mainly composed of tungsten carbide, titanium carbide (TiC) and cobalt. The grade by "YT" ("hard ti" Pinyin prefix) and the average content of titanium carbide. For example, YT15 represents an average WTi = 15%, while the others are tungsten titanium cobalt carbide with tungsten carbide and cobalt content. The tungsten titanium tantalum (NB) hard alloy is the main component of tungsten carbide, titanium carbide, tantalum carbide (or niobium carbide) and cobalt. This kind of hard alloy is also called universal cemented carbide or universal hard alloy.

- Q: How are cemented carbides separated from the cutting tools?

- Brazing heating to melt after the pain, you can take off!

Send your message to us

Ferro Silicon Popular In Iron Casting CNBM Fortune500

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords