Ferro Silicon Origin In Henan Province CNBM China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ferro Silicon Description

Ferro Silicon is a kind of ferroalloy which is composed of ferrum and silicon. Ferro Silicon uses coke, quartz

(or silica) as raw materials and is made by electric furnace. Because silicon and oxygen are easily compound

into SiO2, the ferrosilicon is often used as deoxidizer in steelmaking.

Ferro Silicon Application

1. Fesi 75% is often used as deoxidizer in steel- making.

2. Ferrosilicon also can be used as alloy elements join agent, which is widely used in low alloy steel, non-ferrous metal, bearing steel, heat-resistant steels and electrician silicon-steel.

3. It can be used as a reductant in ferroalloy production and chemical industry.

4. In iron industry it can be used as inoculant and nodulizer.

Specification

Brand | Chemical Composition (%) | ||||||||||

Si | Al | Ca | P | S | C | Fe | |||||

<= | |||||||||||

FeSi75-A | 74.0-80.0 | 1.5 | 1 | 0.035 | 0.02 | 0.2 | Balance | ||||

FeSi75-B | 72.0-80.0 | 1.5 | 1 | 0.04 | 0.02 | 0.2 | Balance | ||||

FeSi72 | 72 | 1.5 | 1 | 0.04 | 0.02 | 0.2 | Balance | ||||

FeSi70 | 70 | 1.5 | 1 | 0.04 | 0.02 | 0.2 | Balance | ||||

FeSi65 | 65.0-72.0 | 2 | 1 | 0.04 | 0.02 | 0.2 | Balance | ||||

FeSi45 | 40.0-47.0 | 2 | 2 | 0.04 | 0.02 | 0.2 | Balance | ||||

Packaging & Shipping

1. Plastic bag(antiproof) +Iron barrel, all adjustable to customer's specific demands.

2. Shipment within 3 working days after production.

Ferro Silicon Size

0-3mm,3-10mm,10-100mm or as the customers’ requirements

Packing

25Kg/bag, 1MT/bag or as your requirements.

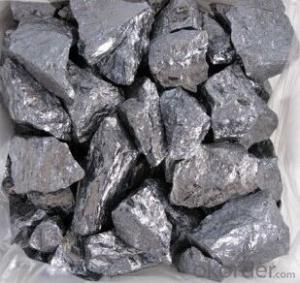

Picture

- Q: Can hard alloy be welded with silver electrode?

- Hard alloy can use silver electrode welding, some more liquid silver wire than general tin brass or iron brass, the cost is too high, the strength level than the ordinary copper electrode should be higher, personal suggestions for the selection of copper base up instead of silver electrode, such as the WEWELDING 46 electrode (referred to as Odin Wei 46 If the strength of electrodes), the structure is higher than silver, if it is to achieve the high permeability, it is still the ideal to silver, only from the strength level, is not WEWELDING 46 copper based electrode.

- Q: CNC alloy milling cutter how to produce?What is the cutting edge of the machine tool?What is the surface coating?What is the cost of plating?Prawns talk about it in detail, I do alloy accessories, I would like to learn some processing methods ~ ~!

- The price varies from a few thousand dollars to a few days depending on the size of the blade and the specificity.Surface coating is usually coated with titanium (such as titanium nitride, etc.)Large manufacturers such as diamond coating equipment general equipment in the tens of millions of yuan in cost is quite high, in Jiangsu there is a foreign company specialized in coating equipment sold to undertake external coating business, the coating cost with you a coated blade is related to the price from a few dollars to tens of dollars / piece / slice.

- Q: Detailed comparison of cemented carbide with diamond properties

- Diamond is hard and brittle, with excellent performance, most of the material processing, as is the emerging industry, the production level is uneven, the high price range; processing hard alloy is less, the price is relatively cheap, because it is a traditional industry, level of production is relatively mature. If you are now worried about the choice of a tool for processing, using diamond tools or carbide tools?

- Q: Compare the advantages and disadvantages of high speed steel and cemented carbide

- Must be in a hardened state, in high speed steel iron, chromium, tungsten and carbon forming hard carbide can improve the wear resistance of steel (hardness of HRC6468). Another part of tungsten dissolved in the matrix, increase the hardness of steel red.High speed steel can reach 650 degrees of red hardnessHigh speed steel has good strength and toughness, cutting edge is sharp after grinding, and its quality is stable. It is used to make small and complex cutting tools

- Q: Hard alloy die polishing with what can be reached Ukraine black brightness

- What if this need to die, the smaller diameter must be black if the large diameter is bright, with a diamond grinding paste and polishing powder

- Q: Material properties of Cemented Carbides

- Metal carbides, especially B, B, IV V VI B metal carbide melting point is above 3273K, the TAC hafnium carbide, respectively 4160K and 4150K, is the highest point currently know material. Most of the carbide hardness large, their microhardness is higher than 1800kg mm2 (micro hardness is hardness says one way for hard alloy and hard compound, microhardness 1800kg mm2 is equivalent to a diamond a Mohs hardness of 9). Many carbides are difficult to break down at high temperatures, and their antioxidant power is stronger than their constituent metals. Titanium carbide has the best thermal stability in all carbides, and is a very important metal type carbide. However, in an oxidizing atmosphere, all carbides are readily oxidized at high temperatures, which can be said to be a major weakness of carbides. In addition to carbon atoms, nitrogen atoms and boron atoms can also enter the voids of the metal lattices and form interstitial solid solutions. They are similar to the gap carbide in that they can conduct electricity, heat conduction, high melting point, high hardness and great brittleness at the same time. The matrix of cemented carbide consists of two parts: one is a hardening phase, and the other is a bonding metal. Is the hardening phase transition metal carbides in the periodic table of elements, such as tungsten carbide, titanium carbide, tantalum carbide, their hardness is very high, the melting point of 2000 DEG C, and some even more than 4000 DEG C.

- Q: What are the common kinds of cemented carbides?

- The grade by "YW" ("hard", "million" Pinyin prefix) and sequence number, such as YW1. (2) grade, composition, performance and application of commonly used hard alloy (see table below) categories of chemical composition of W/% grade performance scope of tungsten cobalt alloy YG3X 96.5 - < 0.53 for cast iron, nonferrous metals and alloy fine boring, fine car, can also be used for fine machining of alloy steel, Quenched steel and tungsten and molybdenum materials; high tungsten carbide content, binder content is low, its high hardness, flexural strength is low; therefore, YG3 is suitable for finishing; whereas the YG15 can bear larger load, suitable for roughing. Suitable for cast iron, nonferrous metals and alloys and non metallic materials roughing during continuous cutting, interrupted cutting of the semi refined car, fine car for percussive rotary drilling machine drilling hard rock, containing coal cutter teeth, hard rock drill, well drilling hard rock percussion drill bit, stamping die, planer and knife for percussive rotary drilling machine and other chisel hard and extremely hard rock, in the epidermis processing great work under stress perforation and stamping tools tungsten titanium cobalt alloy YT5 855 - 10 for carbon steel, alloy steel, forging, stamping, casting, uneven section, rough turning, discontinuous cutting the rough plane semi finishing.

- Q: How are cemented carbides separated from the cutting tools?

- The hard alloy cutter head and the tool body junction part are heated to 600~800 degrees, and the solder can be melted, and the cutter head and the cutter body of the carbide cutter can be separated.Cemented carbide is a kind of alloy material made by powder metallurgy process of hard metal and bonding metal of refractory metal.Hard alloy with high hardness, strength and toughness, good wear resistance, heat resistance, corrosion resistance and a series of excellent performance, especially high hardness and wear resistance of it, even at a temperature of 500 DEG C also remained unchanged, at 1000 degrees C still have high hardness.Hard alloy is widely used as a tool material, such as turning, milling, planing, drilling, boring, used for cutting cast iron, non-ferrous metals, plastics, chemical fiber, graphite, glass, stone and steel, can also be used for cutting steel, stainless steel, high manganese steel, tool steel and other hard processing materials.

- Q: What does "YC20.1 carbide" brand mean?

- Quality solutionsSimply putZhuzhou diamond new standard welding carbide YC201, HRA91.8, 11.79g/cm3, 1400M

- Q: What are the types, codes, and range of application of cemented carbides?

- I am also engaged in carbide industry, different grades (there are ISO brand, there are some domestic brands, and some even use the manufacturer's own brand) on behalf of the composition and use of the barrier.. Because of the wide variety of brand names, the average person will only involve one or several specific industries, and there is no need to know all the code names and their detailed performance... Therefore, we usually produce or recommend the brand (code name) according to the performance and use of the customer..Customers are generally in order before provide you with detailed performance parameters, although not in the factory name brand in different, but according to the performance parameters of the still commonly found in different plant in the corresponding or similar grades, but some brands of blade complex, and complex composition, tell you some properties can not be done with the original brand as like as two peas.. In the blade field, there is still a big gap between China and foreign countriesAlso, due to the development of hard alloy, grade ISO has lost his original meaning of..K20, K30, K40, K05.. And so on, people don't seem to know what they want, if my client told me that these ISO grades, I basically have to provide him with detailed performance parameters..Friends, you are in that industry, our company mainly engaged in geological and mining products (ball gear, drill chip, pick, engineering, knife, shovel snow tooth.Etc)

Send your message to us

Ferro Silicon Origin In Henan Province CNBM China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches