Chinese High Quality High Carbon Ferro Chrome with Best Price

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Chinese High Quality High Carbon Ferro Chrome with Best Price

Pictures:

Chrome is always used to improve the antioxidation and corrosion resistance of steel to make the surface of steel after it is oxidized to form strong adhension oxide film. Then it stops being oxidized or decelerates being oxidized.Micro-Carbon ferro chorme is applied to making stainless, acid-resistant steel and heat resistant steel.

Chrome is mainly used to improve the antioxidation and corrosion resistance of steel to make the surface of steel after it is oxidized to form strong adhension oxide film. Then it stops being oxidized or decelerates being oxidized. Micro-carbon ferro chrome is applied to making stainless steel, acid-resistant steel and heat resistant steel.

Specifications

High Carbon Ferro Chrome

1. Original manufacturer

2. The stability of the shipments

3. Free samples

4. Relatively lower cost

Products information

1. It can be used to produce FerroChrome and Chrome metal in metallurgy industrial.

2. As a kind of steel addition,it is used to produce various special steels with high strength,corrosion resistance,anti-friction,thermostability and anti-oxydic.such as stainless steel,acid-resistant steel,heat-resistant steel,spring steel,tool steel and so on.

3. Chromite is used to produce Chrome brick,,Chrome-magnesium brick and other special refractories in fireproofing.

Content information

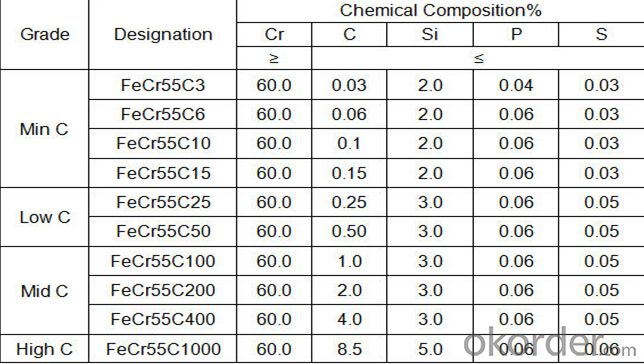

1).ChemicalCompositions:Fe,Cr,C,Si,P,S

2).Type:High,Medium,low,MicroCarbon

3).FeCr67C6.0,FeCr55C600,etc

4).Improve antioxidation.

Packaging & Delivery

Packaging Detail: | 1MT/BAG |

Delivery Detail: | 15-30days |

- Q: What type of carbide for punching dies? Better. Where can I buy it?

- Stamping die is divided into cold stamping and hot stamping, need more different uses to choose different characteristics of carbide brand, you can understandZhuzhou same cemented carbide.

- Q: What is called cemented carbide?

- Hard alloy with high hardness, strength and toughness, good wear resistance, heat resistance, corrosion resistance and a series of excellent performance, especially high hardness and wear resistance of it, even at a temperature of 500 DEG C also remained unchanged, at 1000 degrees C still have high hardness. Hard alloy are widely used as tool materials. Such as turning, milling, planing, drilling, boring, used for cutting cast iron, non-ferrous metals, plastics, chemical fiber, graphite, glass, stone and steel, can also be used for cutting steel, stainless steel, high manganese steel, tool steel and other hard processing materials. Hundreds of times now cutting speed of new carbide tool is carbon steel.Carbide can also be used to make rock drilling tools, mining tools, drilling tools, measuring tools, wear-resistant parts, metal abrasives, cylinder liner, precision bearings, nozzles and so onIn the past twenty years, coated carbide also come out in Sweden.1969 in the successful development of titanium carbide coated tools, the tool is a matrix of tungsten carbide titanium carbide cobalt alloy or cobalt tungsten carbide, titanium carbide surface coating thickness of only a few microns, but with the same grade alloy tool compared to prolong the service life of 3 times, cutting to increase the speed of 25% ~ 50%.20 in 70s has been fourth generation coating tools, can be used for cutting hard processing materials.

- Q: We'll drill on the stainless steel column. Which bit is better?

- If it's cylindrical carbide, it's better to be on the drill bit or as a guide

- Q: What are the types and specifications of carbide cutters?

- The main components are tungsten carbide, titanium carbide (TiC) and cobaltThe grade by "YT" ("hard ti" Pinyin prefix) and the average content of titanium carbide.For example, YT15 is a tungsten titanium cobalt carbide that represents an average WTi = 15% and the remainder is tungsten carbide and cobalt content

- Q: Can ceramic tools process cemented carbides?

- Specific to the needs of carbide processing brand to determine,Cemented carbide, such as tungsten carbide, can be machined with a CBN toolReference: "CBN tools for processing hard alloy material, Valin super hard"

- Q: Material properties of Cemented Carbides

- Metal carbides, especially B, B, IV V VI B metal carbide melting point is above 3273K, the TAC hafnium carbide, respectively 4160K and 4150K, is the highest point currently know material. Most of the carbide hardness large, their microhardness is higher than 1800kg mm2 (micro hardness is hardness says one way for hard alloy and hard compound, microhardness 1800kg mm2 is equivalent to a diamond a Mohs hardness of 9). Many carbides are difficult to break down at high temperatures, and their antioxidant power is stronger than their constituent metals. Titanium carbide has the best thermal stability in all carbides, and is a very important metal type carbide. However, in an oxidizing atmosphere, all carbides are readily oxidized at high temperatures, which can be said to be a major weakness of carbides. In addition to carbon atoms, nitrogen atoms and boron atoms can also enter the voids of the metal lattices and form interstitial solid solutions. They are similar to the gap carbide in that they can conduct electricity, heat conduction, high melting point, high hardness and great brittleness at the same time. The matrix of cemented carbide consists of two parts: one is a hardening phase, and the other is a bonding metal. Is the hardening phase transition metal carbides in the periodic table of elements, such as tungsten carbide, titanium carbide, tantalum carbide, their hardness is very high, the melting point of 2000 DEG C, and some even more than 4000 DEG C.

- Q: What are the carbide inserts on the turning tool welded to the handle?

- The first copper burned in the post, and then the borax fell on the top, then put on top of the alloy blade, borax fell on the alloy blade above the flame cutting with money. Be careful not to use the high pressure oxygen valve. Wait until the copper water flows out evenly. Let him cool naturally,

- Q: Import all carbide drill bit, mainly those brands

- Good (maford), Kenna, Thomas, di tex, Sandvik, guhring general in the domestic production, the performance of discount.Now on the market is generally a bit alloy steel material whole bit, although the materials are the same, but due to the processing technology, various brands of product quality disparity. Imported and domestic alloy drills are also very different.Imported alloy bit usually adopts VHM micro grain hard alloy (ISO K40), the type of ultrafine particles (0.6 m) in the application of high performance drill and ordinary milling machine, the hardness and toughness of the ideal together.Take high quality alloy bit surface coating, such as chromium aluminum nitride (AlCrN) coating, the coating layer of coating, the thickness of 4 m, the micro hardness is up to 3200HV, the friction coefficient of 0.35, thermal stability up to 1100 degrees celsius. After coating, the drill color is bluish gray.After coating, the alloy drill can process low alloy steel and high strength steel. High steel can reach 54HRC.

- Q: Do you want to center hole? How deep is fit? Or do not hit it directly? My drill bit and the center hole contact point are easy to collapse

- A very shallow point can be;Because once too deep, and the center hole of the aperture is less than the drill bit to drill aperture, so is not in contact with the workpiece, but the main cutting edge part in contact with the workpiece, so cause drill can not correctly centering, so easy to collapse;In the deep hole processing, it is necessary to use pre hole; the general pre hole is the drill bit, the hole size is the same, and the depth is usually about 3 times;I hope I can help you

- Q: Hard alloy and cast iron join together, use temperature 150 degrees, what glue is better to use?

- High temperature resistant high strength metal and carbide inorganic adhesive YL04-3. For the structure of all kinds of cutting tools such as bonded &def hard alloy cutter and lengthened drill, geological drill; casting airhole crack repair; use temperature of -196 DEG ~800 DEG

Send your message to us

Chinese High Quality High Carbon Ferro Chrome with Best Price

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches