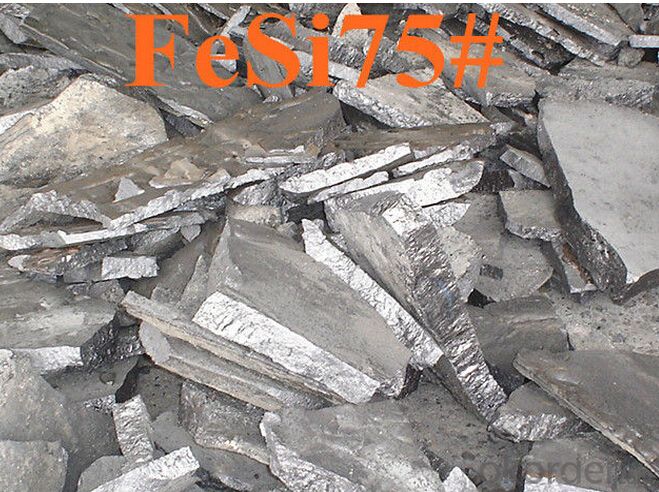

FeSi 72 For Making Ductile Cast iron

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

FeSi 72 for making ductile cast iron

1.13 years' professional experience

2.Controlled composition&size

3.ISO&SGS QA

FeSi 72 for making ductile cast iron

Description

Ferro Silicon is a kind of ferroalloy which is composed of ferrum and silicon. Ferro Silicon uses coke, quartz (or silica) as raw materials and is made by electric furnace. Because silicon and oxygen are easily compound into SiO2, the ferrosilicon is often used as deoxidizer in steelmaking.

Application

1. Ferrosilicon is often used as deoxidizer in steel- making.

2. Ferrosilicon also can be used as alloy elements join agent, which is widely used in low alloy steel, non-ferrous metal, bearing steel, heat-resistant steels and electrician silicon-steel.

3. It can be used as a reductant in ferroalloy production and chemical industry.

4. In iron industry it can be used as inoculant and nodulizer.

Specification

Brand | Chemical Composition (%) | ||||||||||

Si | Al | Ca | P | S | C | Fe | |||||

<= | |||||||||||

FeSi75-A | 74.0-80.0 | 1.5 | 1 | 0.035 | 0.02 | 0.2 | Balance | ||||

FeSi75-B | 72.0-80.0 | 1.5 | 1 | 0.04 | 0.02 | 0.2 | Balance | ||||

FeSi72 | 72 | 1.5 | 1 | 0.04 | 0.02 | 0.2 | Balance | ||||

FeSi70 | 70 | 1.5 | 1 | 0.04 | 0.02 | 0.2 | Balance | ||||

FeSi65 | 65.0-72.0 | 2 | 1 | 0.04 | 0.02 | 0.2 | Balance | ||||

FeSi45 | 40.0-47.0 | 2 | 2 | 0.04 | 0.02 | 0.2 | Balance | ||||

- Q: The use of cemented carbides YG and YT

- Three, need to point out is: YG, YT, YW each alloy has different models, each model has different applicable range, the above refers to the comprehensive analysis.

- Q: How to distinguish cemented carbide grades?

- (3) titanium cobalt tungsten tantalum carbide (WC+TiC+TaC+Co)) (YW YS) "the main processing of heat resistant steel, high manganese steel, stainless steel and other hard materials processing" in addition to TaC YT hard alloy on (NbC), improve the bending strength, impact toughness, high hardness, wear-resistant and anti oxygen ability. Can be processed and can be made of steel, cast iron and non-ferrous metals. It is often called the universal hard alloy (also known as the universal hard alloy). The following is a variety of grades, density, bending strength, hardness and flexural strength hardness grade use density of use of YG3X 14.6-15.2 132092 is suitable for cast iron, nonferrous metals and alloy steel small alloy steel cutting section of high-speed machining. K01 YG3X YG6A 14.6-15.0 137091.5 for hard cast iron, non-ferrous metalsalloys, also suitable for high manganese steel, hardened steel, alloy steel and semi finishing K05 YG6A YG6X 14.6-15.0 finishing. 142091 it is proved that the alloy processing of chilled alloy cast iron and alloy steel can obtain good results, finishing is suitable for ordinary iron. K10 YG6X YK15 14.2-14.6 210091 for the whole processing of drilling, milling, reaming and alloy cutter. Have high wear resistance and toughness of K15. K20 YK15 YG6 14.5-14.9 138089 is suitable for cast iron, nonferrous metals and alloy non metallic materials at medium cutting speed precision. K20 YG6 YG6X-1 14.6-15.0 150090 is suitable for cast iron, nonferrous metals and alloy non metal material during continuous cutting finishing, discontinuous cutting the semi refined car, fine car, small car, coarse fine car section thread, continuous section semi finishing milling and finish milling, rough and fine hole expansion. K20 YG6X-1 YG8N 14.5-14.8 200090 is suitable for cast iron, cast iron, ductile iron and chromium, High speed machining of nickel stainless steel alloy.

- Q: Hello, what's your company? What do you do with carbide? Thank you in advance

- Pro, what do you mean by that question? We are the hard alloy recycling companies, focus on hard alloy recovery, Qingdao cemented carbide business network, with the recovery of hard alloy scrap, hard alloy die, tungsten steel scrap recycling

- Q: How to distinguish the authenticity of Zhuzhou diamond brand cemented carbide blade?

- Zhuzhou diamond brand cemented carbide blade is the first brand in our country. We can distinguish its authenticity from the following aspectsVisual package: it is packed in plastic box, the upper and lower cover are transparent plastic, and the bottom box is blueNormative labels: according to the ISO standard, lists the recommended types of processing materials, bar code identification, marked "diamond brand" trademark and "China well-known trademark" and enterprise logoType anti-counterfeit: each piece of hard alloy welding machine, clamping blade convex superscript "ZCCT" logo, direct press formingSealing anti-counterfeiting: labels and sealing paste affixed to the interface of the packaging box, one-time paste, can not be pasted after tearingZhuzhou Jing Jing carbide sales Co., Ltd.

- Q: Classification of Cemented Carbides

- 1 tungsten cobalt carbide2, tungsten, titanium and cobalt carbide3, tungsten, titanium, tantalum (niobium) carbide

- Q: Carbide products which are used more?

- Sealing rings in the sealing industry, mould industry, machine tools, milling cutters, drill bits in the mining industry, and armor piercing shells in the army, etc.

- Q: One kind of steel is called T10, and another is carbon steel. What kind of hardness and strength do they have?

- Uncertain.Carbon content is different, and some trace elements contain different categories.Alloy steel, which means hardening can harden even when cooled in air, and very sharp. It is a complex alloy steel, containing tungsten, molybdenum, chromium, vanadium and other carbide forming elements. The total amount of alloy elements is about 10 to 25%. It can maintain high hardness at high temperature (about 500 DEG C) in high speed machining, and HRC can be higher than 60.Carbon steel, also called carbon steel, mainly refers to the mechanical properties of carbon depending on the content of steel, and generally do not add a large number of alloy elements of steel, sometimes referred to as general carbon steel or carbon steel. Of iron carbon alloys containing carbon less than 2% WC. Carbon steel, in addition to carbon, usually contains a small amount of silicon, manganese, sulfur and phosphorus.

- Q: Processing stainless steel 301 milling thickness of about 3 millimeters, with what blade good?

- Friends, according to your question, if change my words, I choose YS25Grade ISO grouping, code name, density, bending strength, hardness, useYS25 12.8 P25 13.2 = 1780 = 90.5 for carbon steel, cast steel, high manganese steel, high strengthRough turning, milling and planing of steel and alloy steel

- Q: Model of grinding carbide wheel sheet

- Go online and check it outCould you show me a picture of the gold foil?

- Q: YW2 carbide blade type

- YW2 general cylindrical turning tool head type: A325 20pcsCemented carbide is a kind of alloy material made by powder metallurgy process of hard metal and bonding metal of refractory metal.Hard alloy with high hardness, strength and toughness, good wear resistance, heat resistance, corrosion resistance and a series of excellent performance, especially high hardness and wear resistance of it, even at a temperature of 500 DEG C also remained unchanged, at 1000 degrees C still have high hardness.Hard alloy is widely used as a tool material, such as turning, milling, planing, drilling, boring, used for cutting cast iron, non-ferrous metals, plastics, chemical fiber, graphite, glass, stone and steel, can also be used for cutting steel, stainless steel, high manganese steel, tool steel and other hard processing materials.

Send your message to us

FeSi 72 For Making Ductile Cast iron

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords