Factory price WPC Outdoor Flooring/Composite Decking

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m

- Supply Capability:

- 20000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Wood Plastic Composite Decking Made in China

一.Product Description:

. With natural wood grain and looks like nature wood, less timber problems.

. Approx. 90% recycled materials, environmental friendly, saving forest resources.

. No paint, stain or oil required, low maintenance.

. Weather resistant, suitable from –40°C to 60 °C.

. Resistant to termite and insect attack, will not split, rot or warp.

. Easy to install and low labor cost.

. Cutting and drilling like timber.

. Span is 300~400mm.

. Six standard colors, standard length 2.2m or 3.6m, custom length available.

escriptions :

The characteristics of Wood generally had the problem of Waterproof and the serious concern to the environmental protection has been increasing day by day as well as it caused the Governments worldwide to stipulate the law to restrict to fell trees to reach the goal. To satisfy with the market's demand we utilized the characteristics of macromolecule to combine with the high technology of heavy pressure-micro foaming to produce an unique product with the invention and innovation of revolution. We call this new product " CELLwood®".

Properties :

1. 100% recyclable product meets with the environmental protection without

adding any wood flour or sawdust.

2. 100% waterproof.

3. Suitable to be used for the activities indoor and outdoor.

4. The component with high quality features that the density is similar to the wood

(D:0.6~0.7 g/cm3) and light.

5. The processing is similar to the general timber, e.g.: shave, saw, trim, nail, drill,

wash and grind.

6. Strong rigidity and durability. (Similar to teak)

7. Thermal process is easily executed to be blended to have various shapes of the

materials.

二.Technical Data

Slip resistance:

Boards of Techwoodn according to ASTM D2394-05. This is the best ranking for bare-foot slip resistance.

Weathering resistance:

Boards of Techwoodn have very low moisture uptake.This is key for mold and mildew resistance.

UV resistance:

4000 hours accelerated Xenon-arc Exposure,the Boards turned slightly more clear and colored.

Abrasion resistance:

The resistance to abrasion is similar to oak.

Fungus resistance:

Whatever fungus the wood composite is exposed to,it is extremely durable.

Moreover,aging test does not affect this durability.

三. FAQ

. What kinds of wpcproducts do you have?

We have wpc decking in different size, fence series (only wpc material or connect with aluminum profiles, decking tile series.

. Is it difficult to install the wpc board?

No, it is easy to install. Using the tool which you use to install the real wood. Fix the board on the substructure with clips.

. Can you stick the label with our logo on the boards?

Yes, please provide the label drawing, we can stick the customized label on the board.

. What documents are available?

A full range documents, including products pictures, installation guide and relative certificates can be provided; Further more, customs declaration is provided. This is an one-stop service for you.

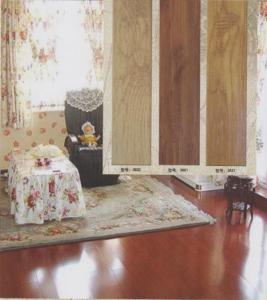

四. More picture for your reference

- Q: right now we have a concrete painted floor in our basement and i hate it, the paint always chips. does anyone know what we can do with the floor?

- Use an Epoxy floor paint. We just finished turning the basement into a entertainment area. The cement floor had been painted with a brown paint and it was faded and peeling. I went to my local hardware store and bought two gallons of jade green epoxy paint and the floor look unreal. Everybody that comes over for movies in surround sound asks how we made the floor look so good. You can take the paint and have it mixed to any color you choose. I would pick up a paint chip booklet from the local paint store and bring it home and see which colors look the best in your basement. Then have the colored mixed and remove everything from your floor and roll on your paint. Our floor looks like a very expensive floor because the color is so surreal, If you like jade try that color or just pick out your favorite color. This paint covers everything and last forever. We have a really cool place to just hang out now. You can make your floor look new with one coat.

- Q: Saw a floor of the substrate is black, this is not the quality of the floor is also very good brand more

- Because it is not very good because the quality of the quality of the floor substrate should show the natural pine, poplar color; inferior flooring substrate due to the production process did not use high-quality logs and the selection of wood, shrubs; or to reduce costs To the veneer, so the color of the inferior substrate will show dark brown

- Q: is there soil on the ocean floor

- There are silt / clay deposits out toward the middle, and there is sand and other coarse deposits near shore. The heavier the particle, the sooner it settles onto the ocean floor when it is carried there by a river. And it's called sediment, not soil. Soil is a dry land phenomenon.. Plus, where there are plate boundaries, magma comes up and cools, forming basalts, etc.

- Q: When you replace carpet in a room because you want to install hardwood... do you need to replace the subflooring? Do you replace sub flooring every time you replace flooring?

- Only if the subflooring is damaged or uneven or weak or warped. If it's flat and solid, just reuse it.

- Q: Hi I was just wondering if anyone knows of a good way to clean Laminate floors without smears. Thanks. x

- I can only tell you how I do mine, I use Mr. clean lemon scent and a micro fiber flat mop. I wash the whole floor and them rinse the mop head real well and then again go over the floor with clean warm water. That's it.

- Q: 502 glue dripping on the wooden floor how to do? How to get rid of 502 glue?

- 1 in the original place to drop the pool of short overestery tea compensation 502 to melt the original 502, and then quickly washed with water, very spiritual! 2. C and the same solution can be washed. Small area of adhesive 502 glue, as long as the hot water can be soaked, if a large area stained with 502 glue, coated with acetone, about 5 to 10 minutes can be removed if you are drops of a drop, it is recommended that you use 1 Oh , I tried, but I was drops on the table

- Q: What restaurants have floor seating where you sit on the ground and eat? I really want to go to one.

- I know of two such restaurants. I've been to each of them and recommend them based on the traditional criteria of food/decor/service/value. Coincidentally, both of them are Asian and vegetarian. Both are in Manhattan. Vatan, 409 Third Avenue (at 29th Street). Indian. All you can eat. Seating is not exactly on the floor -- it's on a raised platform, about 20 inches off the ground. There's no place to dangle your legs, so you have to keep them on the platform with the rest of you -- in that respect, it's just like sitting on the floor. HanGawi, 12 East 32nd Street (between Fifth & Madison Avenues). Korean. Seating is on the floor, but there's a well that you can dangle your legs into. You'll need to check your shoes at the entrance, so wear nice socks. Finally, disregard the answer about a Cambodian restaurant at McMillan and Taft -- there are no such streets anywhere in New York City.

- Q: Home to decorate, I heard that solid wood flooring to take care of the composite floor to be often like wax. But it is said that solid wood flooring for a long time there will be cracks, and stepped up will crunchy. Want to know this is not the case, the way to recommend me to the single toilet to drink 丿 estimated Pitschai Kizhi board to buy what brand it, thank you ~ ~ more

- If you want to be healthy, then it is a solid wood floor. As take care of it, whether or wood flooring, waxed once every six months so the floor can be well protected if wax play too frequently or too little, both on the floor is not good. and there is no glue wood flooring, as opposed to the human body, it is very safe. toxic paint, no volatile year also. the gum will forever be with you. it always has a taste of the factory. Because my company to produce the floor, but unfortunately, not in China sales, so I suggest you, to the kind of formal decoration market, get the floor to see if it is real wood. However, a simple look from the side, you can see out. or secretly destroyed it with a fingernail, if it is fake wood, it is a leakage level. then, highlights a certain smell floor, is not it great that smoked people's taste, and the eyes will not want to feel a kind of astringent tears to stay. If not, prove that the paint on the floor still green. any manufacturer of wood products, are environmentally friendly and ordinary type. so, the same thing, your good. this is also some building materials Do your reason. Just because real materials, environmental protection. As for the sound of creak, that is when the shop floor, there is no good ground leveling. There's nothing directly to do with wood or laminate flooring.

- Q: i want to replace the old carpet to laminate flooring. can anyone provide me with a step by step guide on how to do this? i have also purchased some underlayment for laminate flooring to go along with the flooring.

- Installing laminate is pretty easy in most cases. Remove all base boards. Make sure the floor is clean. Role out your sound bearrier. Tape the seams using a wide masking tape. You'll need a laminate wood block to connect you laminate together. Your peices that end up next to the wall will have to be a little short to fit in place. In door ways lay a scrap piece upside down and take a saw and cut out door jams to your laminate fits under door jams. Hope this helps some. I've installed for years.

- Q: I want to buy a steam mop to clean my laminate floors, but am afraid that the moisture may hurt the laminate. Please advice, thank you

- any would work :D i did it its fine

Send your message to us

Factory price WPC Outdoor Flooring/Composite Decking

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m

- Supply Capability:

- 20000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords