Factory Hot Sell Amino Trimethylene Phosphonic Acid

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

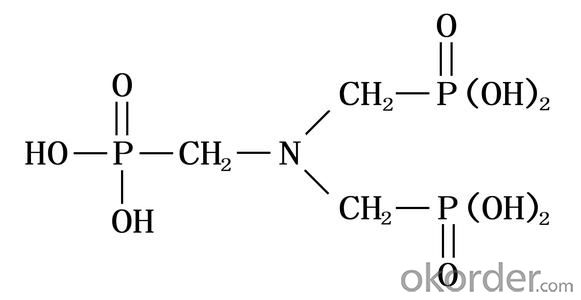

Amino tris(methylene phosphonic acid) / Amino Trimethylene Phosphonic Acid/ ATMP / 6419-19-8 / C3H12NO9P3

CAS No. 6419-19-8

Molecular Formula: N(CH2PO3H2)3

Molecular weight: 299.05

Structural Formula:

Properties:

ATMP has excellent chelation, low threshold inhibition and lattice distortion ability. It can prevent scale formation, calcium carbonate in particular, in water system. ATMP has good chemical stability and is hard to be hydrolyzed in water system. At high concentration, it has good corrosion inhibition.

ATMP is used in industrial circulating cool water system and oilfield water pipeline in fields of thermal power plant and oil refinery plant. ATMP can decrease scale formation and inhibit corrosion of metal equipment and pipeline. ATMP can be used as chelating agent in woven and dyeing industries and as metal surface treatment agent.

The solid state of ATMP is crystal powder, soluble in water, easily deliquescence, suitable for usage in winter and freezing districts. Because of its high purity, it can be used in woven & dyeing industries and as metal surface treatment agent.

Specification:

| Items | Index | |

|---|---|---|

| Standard | Solid | |

| Appearance | Clear, Colorless to pale yellow aqueous solution | White crystal powder |

| Active acid % | 50.0-51.0 | 95.0min |

| Chloride (as Cl-)% | 1.0 max | 1.0 max |

| pH value (1% solution) | 2.0 max | 2.0 max |

| Fe,mg/L | 10.0max | 20.0max |

| Density (20°C)g/cm3 | 1.31-1.35 | - |

| Colour APHA (Hazen) | 30.0max | - |

Application range&using method:

ATMP is usually used together with other organophosphoric acid, polycarboxylic acid and salt to built all organic alkaline water treatment agent. ATMP can be used in many different circulating cool water system. The recommended dosage is 5-20mg/L. As corrosion inhibitor, The recommended dosage is 20-80mg/L.

Package and Storage:

ATMP liquid: Normally In 30kg or 250kg net Plastic Drum;ATMP solid: 25kg inner liner polyethylene (PE) bag, outer plastic woven bag, or confirmed by clients request.Storage for ten months in room shady and dry place.

Safety Protection:

ATMP is Acidity, Avoid contact with eye and skin, once contacted, flush with water.

Shipping Date: Within 7-10 workdays after receiving your deposit.

Our Service:

Own Lab and joint venture factory.

Superb r&d team;Safety standardization production.

Rich experience in export and strong logistical support.

Good relationship with many large domestic pharmaceutical factory.

Perfect service, perfect supply chain.

- Q: Are biological enzymes harmful to humans?

- Recently, people are increasingly interested in the use of enzymes in cosmetics, not only from a technical point of view, but also from the market prospects and consumer awareness of these seemingly effective raw materials. Enzymes have been used in laundry detergent for more than 20 years and are linked to long-term performance with the ability to provide and enhance strong stain removal capabilities. According to some speculation, their positive response in the market may be interpreted as satisfying the aging population, the pursuit of younger needs to enhance the performance of cosmetics. The natural shedding process of the skin is controlled by the enzymatic reaction, and the specific enzyme dissolves the cell desmosomes that release the dead epidermal cells. These enzymes are produced in dead keratinocytes. Their active sites are phagocytosed with mercapto groups, and cleavage of peptide bonds in a manner similar to that of thio-glycolic acid and mercaptoalanine (plus derivatives) when the hair is broken. Use these types of enzymes and it

- Q: Why can't catalysts make an unfavorable reaction favorable?Can anyone give me a relatively simple explanation for this?Thank you so much in advance!

- Catalysts, as enzymes, only change the activation energy (the energy the compound needs to gain to transform into products), they don't change the Gibbs energy values of reactants nor products. Therefore, if the delta G of the reaction is positive, it'll still need free energy to complete. They make a reaction complete faster than in normal conditions, but don't change the actual possibility for that reaction to happen. In the human body, a lot of reactions of catabolism have a positive G value and these reactions needs to get energy from other coupled reactions that have a negative value, so the total value is still negative. Many of them use hydrolysis of ATP to provide that energy, as its hydrolysis is about -30 kJ/mol in physiological conditions. I don't know what class you're in to ask this question, so can't really know if this answer is too simple or complicated for u... sorry in advance! Jo?l

- Q: I dont know what it is but when i open up my computer it comes up and it says that its not working? so i really dont know what to do.

- Catalyst is what ATI calls the drivers for their video cards or video devices built into mainboards. Download the newest video driver for your video card from ATI or from your computer manufacturer's site if the video device came with the computer. Install that, and you should be all set. You may want to check your add and remove programs and remove any of the old, malfunctioning ATI or Catalyst drivers before attempting to install the new one. Good luck!

- Q: What is the quality of the catalyst in the chemical reaction, for example, 34.3 g before the hydrogen peroxide reaction, 32.7 g after the reaction, and how much is the catalyst mass?

- You can not calculate this question, the quality of the catalyst before and after the same reaction, how much reaction before the reaction on how much

- Q: How are a catalyst and an intermediate similar? How are they different?

- A catalyst speeds up the rate of a reaction by lowering the activation energy barrier which is, presumably, the energy required to achieve the reaction intermediate. Catalysts are also not consumed in the reaction, they are regenerated towards the end. A reaction intermediate is a configuration that a molecule takes prior to achieving it's lowest energy form which would signify the end of the reaction. Intermediate usually are hard to isolate because of the incentive to go to the most stable configuration. How are they different? A catalyst is not a part of the reaction product and it doesn't get consumed. An intermediate in a reaction is transformed into the product. How are they similar? Well, catalysts drive the reaction and make it easier for the reaction for follow through. Since intermediates are high energy and thermodynamics tells us that low energy is favorable, the incentive for a high energy intermediate to drive down to it's stable for can also drive a reaction. I hope that helps. I hope it makes sense.

- Q: Comparison of biocatalysts with chemical catalysts!

- Differences: 1, the biocatalyst has a higher efficiency of the catalytic capacity; its efficiency is the general inorganic catalyst 10 of the power of 10 ~ 10 13 power.

- Q: How the catalyst accelerates the chemical reaction

- Reduced the activation energy required to reflect

- Q: What is the difference between biological and chemical catalysts?

- Biological catalyst: 1. Biological catalysts or enzymes are high molecular weight globular proteins. 2.Their composition may change at the end of reaction. 3.Their catalyzing effect is very high. i.e faster than chemical catalyst. 4.They are reaction specific. i.e One enzyme or biological catalyst may catalyze only particular type of reaction and not many. 5.They are intolerant to temperature and pH changes. An enzyme can not function outside its temperature or pH range. e.g amylase,lipase,pepsin Chemical catalyst: 1.Chemical catalysts are simple inorganic molecules with low molecular weight. 2.They remain unchanged at the end of reaction. 3.They are slower compared to enzymes. 4.They are not reaction specific. 5.They function within wide range of temperatures,pH or pressure. e.g vanadium dioxide, platinum

- Q: Several experiments were carried out using catalysts

- Hydrogen peroxide in the manganese dioxide as a catalyst for decomposition reaction: 2H2O2 == MnO2 == 2H2O + O2 ↑ (laboratory oxygen principle)

- Q: The catalyst can change the chemical reaction process, why is it wrong?

- No, only for the length of time

Send your message to us

Factory Hot Sell Amino Trimethylene Phosphonic Acid

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches