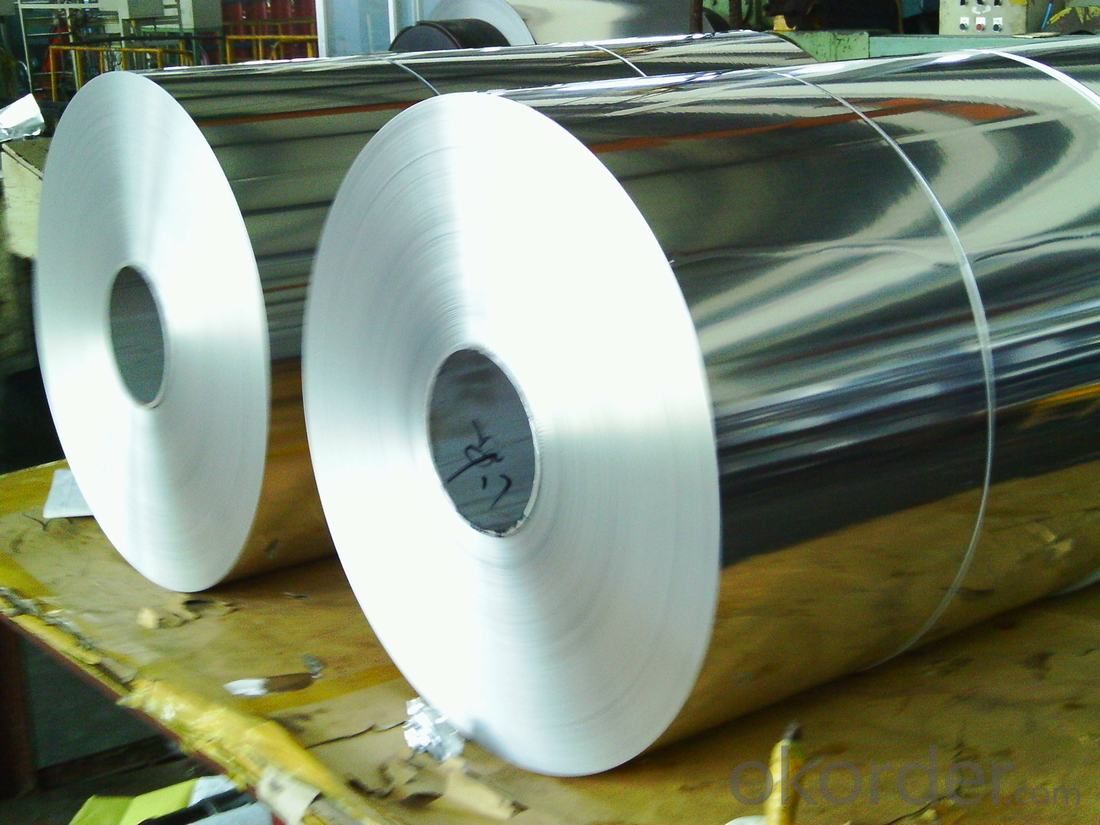

Aluminum Flat Sheets - Extra Wide 1100/1050/1020/1060 Aluminum Coils for Decoration

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 600 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Extra Wide 1100/1050/1020/1060 Aluminum Coils for Decoration

Aluminum Description

-Hot rolling 1100/1050/1020/1060 aluminum coils for roof sheet is used for celling, decorate, ACP,Curtain Wall,Roofing Sheet, PC base, radiator,cookware,deep drawing and more.

- 1 series Aluminum Coils temper: O-H112

-1 Series Aluminum Coils Alloy: 1100/1050/1060/1200/1035/1070

-Thickness: 0.5-10mm

-Width:200-1500mm

-Length:12m Max.

Temper: h14,h16,h18,h22,h24,h26,h32,o/f

Thickness: o.o3mm-3.0mm

Width: 30mm-1700mm

Coating: pe(polyester),pvdf,epoxy

Painting thickness: standard 16-25 mic, max 40 mic

Color: according to ral colors or customer's samples

Packaging & Delivery

| Packaging Details: | Coil ID :508MM Coil Weight : about 2.5 tons or as per customers requirement Packing ; In Export Sea worhty wooden pallets Eye to wall or Eye to Sky One container can be loaded about 20 mts |

| Delivery Detail: | within 25 days after receiving L/C deposit |

- Q: Can aluminum sheets be used as heat shields?

- Aluminum sheets are capable of being used as heat shields. The reason for this is that aluminum possesses exceptional thermal conductivity, enabling it to effectively conduct and transfer heat away from its source. Moreover, aluminum exhibits a high melting point, which enables it to endure high temperatures without distorting or warping. These characteristics render aluminum sheets an optimal selection for heat shield purposes, which encompass safeguarding delicate components and structures from heat-related harm in various industries such as automotive, aerospace, and industrial sectors. Additionally, aluminum is lightweight and comparatively easy to mold, which makes it a practical alternative for heat shields that necessitate installation in confined areas or intricate designs. In summary, utilizing aluminum sheets as heat shields provides efficient thermal protection while offering durability, versatility, and cost-effectiveness.

- Q: are there any carbonated mineral water that are produced in aluminium cans.

- Aluminium cans have an oxide covering on them so the reaction between them and the carbonated water is so little if any that it can't be noticed. Aluminium is also not so high on the reactivity series

- Q: Can aluminum sheets be an alternative to plastic in certain applications?

- Indeed, aluminum sheets have the potential to serve as a viable substitute for plastic in specific scenarios. Aluminum, as a material, possesses the qualities of being lightweight and long-lasting, presenting numerous advantages over plastic. It boasts an outstanding strength-to-weight ratio, rendering it suitable for applications that demand resilience to impact or heavy loads. Furthermore, aluminum exhibits a high resistance to corrosion, making it an excellent choice for outdoor or marine applications where plastic may deteriorate over time. Furthermore, aluminum proves to be an exceedingly recyclable material, aligning with the increasing emphasis on sustainability and waste reduction. Unlike plastic, which can take centuries to decompose, aluminum can be recycled indefinitely without compromising its properties. This renders aluminum a more environmentally-friendly option for applications where plastic waste is a concern. Moreover, aluminum sheets offer superior thermal conductivity in comparison to plastic, making them ideal for applications that necessitate heat dissipation or thermal management. As a result, aluminum emerges as the preferred choice for products like heat sinks or electronic enclosures. However, it is crucial to acknowledge that aluminum sheets may not always be the optimal alternative to plastic. Plastic possesses its own set of advantages, such as its lightweight nature, flexibility, and cost-effectiveness, rendering it more suitable for applications that require these properties. Additionally, plastic can be molded into intricate shapes, making it preferable for certain designs. In conclusion, aluminum sheets can prove to be an effective substitute for plastic in specific applications where their strength, durability, corrosion resistance, recyclability, or thermal conductivity offer advantages. Nevertheless, the ultimate decision between aluminum and plastic hinges upon the specific requirements and limitations of the given application.

- Q: Can aluminum sheets be welded or soldered?

- Yes, aluminum sheets can be welded or soldered. However, the process for each differs significantly. Welding aluminum typically involves using a TIG (Tungsten Inert Gas) or MIG (Metal Inert Gas) welding process, which requires a high heat source and a filler material to join the sheets together. The process can be more challenging compared to welding steel due to aluminum's high thermal conductivity and lower melting point. Soldering aluminum, on the other hand, is a process that involves using a low-temperature solder and flux to bond the sheets together. Specialized solders, such as aluminum solder or solder with a high percentage of tin, are typically used. Soldering aluminum is generally less common and more difficult compared to soldering other metals due to aluminum's oxide layer, which can prevent proper adhesion. In summary, while both welding and soldering can be used to join aluminum sheets together, welding is the more commonly used method due to its stronger and more durable results. Soldering aluminum can be more challenging due to the need for specialized solders and the presence of the oxide layer.

- Q: Aluminum alloy cable tray is made of a series of aluminum sheets, a series of pure aluminum aluminum plate can do?

- 6 Department of the bar, pure aluminum is too soft, in fact, the price of 6 series with pure aluminum prices on the strength of almost guaranteed.

- Q: Can 101 aluminum sheets be painted or coated?

- Certainly! Aluminum sheets offer the possibility of being painted or coated. This adaptable material lends itself to receiving a range of finishes, including paint or protective coating, which can both elevate its visual appeal and safeguard it against corrosion. Whether it pertains to 101 aluminum sheets or any other aluminum variant, diverse techniques like spray painting, powder coating, or anodizing can be employed to paint or coat them. The selection of the appropriate paint or coating shall be contingent upon the desired aesthetics, performance criteria, and the precise utilization of the aluminum sheets.

- Q: What are the standard thicknesses for aluminum sheets utilized in construction?

- <p>Yes, there are standards for the thickness of aluminum sheets used in construction. These standards vary by country and application. In the United States, the Aluminum Association sets standards, such as AA 3003-H14, which is commonly used in construction for thicknesses ranging from 0.020 to 0.250 inches. In Europe, EN 485-2 covers the specifications for aluminum sheet thicknesses. Thicknesses can range from 0.4mm to 6.0mm, depending on the specific requirements of the construction project. It's important to consult the relevant standards for the region and application to ensure compliance and proper material selection.</p>

- Q: Are the aluminum sheets suitable for manufacturing window frames?

- Yes, aluminum sheets are suitable for manufacturing window frames.

- Q: How are aluminum sheets cut or shaped?

- Aluminum sheets can be cut or shaped using various methods such as shearing, laser cutting, waterjet cutting, or CNC milling. Shearing involves using a specialized machine to cut the sheet along a straight line. Laser cutting utilizes a high-powered laser beam to precisely cut or engrave the aluminum sheet. Waterjet cutting involves the use of a high-pressure jet of water mixed with an abrasive material to cut through the sheet. Lastly, CNC milling uses computer-controlled machines to remove material from the aluminum sheet and create intricate shapes or designs.

- Q: Can aluminum sheets be used for insulation purposes?

- Yes, aluminum sheets can be used for insulation purposes. They have a low thermal conductivity and can effectively reflect heat and cold, making them suitable for insulating applications in various industries such as construction, automotive, and packaging.

Send your message to us

Aluminum Flat Sheets - Extra Wide 1100/1050/1020/1060 Aluminum Coils for Decoration

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 600 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords