Equal Angle Steel Cold Rolled for Constraction Application

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 28 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Equal Angle Steel Cold Rolled for Constraction Application at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Equal Angle Steel Cold Rolled for Constraction Application are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Equal Angle Steel Cold Rolled for Constraction Application are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

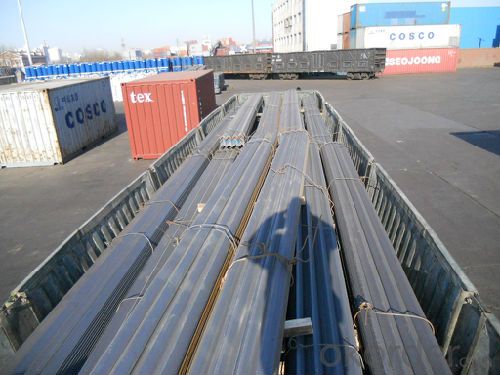

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

304stainless steel angle bar

1.Short time delievry

2.Length:1-12M

3 New produced product, few rust

4 provide your Logo

Hot rolled 304stainless steel angle bar from China ShangHai

Hot rolled 304stainless steel angle bar from China ShangHai | |

| Size | 25mm*25mm-250mm*250mm (Customized size is acceptable, pls contact supplier for more details) |

Wall thickness | 3mm-20mm |

Length | 1m-12m ,Can follow customer’s requiremnts |

Internatioanal Standard | ISO 9001-2008 |

Standards |

ASTMA53/ASTM A573/ASTM A283/Gr.D/

BS1387-1985/

GB/T3091-2001,GB/T13793-92, ISO630/E235B/

JIS G3101/JIS G3131/JIS G3106/

|

Materials |

(We could offer Carbon, Alloy, Stainless steel) Q195,Q215,Q235B,Q345B,

S235JR/S235/S355JR/S355

SS440/SM400A/SM400B

MTC report will be offered together with the shipping document. |

Product Category | Metallurgy,Mineral &Energy |

Technique | Hot Rolled |

Packing | 1.Big OD:in bulk 2.Small OD:packed by steel strips 3.woven cloth with 7 slats 4.according to the requirements of customers |

Usage | Mechanical&manufacture,Steel strcuture, Shipbuilding,Bridging,Automobile chassis , Power tower, frame shef |

Main market | Middle East, Asia, Africa,Europe, America and Australia |

Country of origin | China |

Productivity | 15000 Metric Tons pet Month |

Remark | Payment terms :T/T ,L/C Terms of trade :FOB ,CFR,CIF ,DDP,EXW Minimum order : 10 tons Lead time: 3-15 working days (Can Fast delievery time because of the large stock size and well experience in the whole process of the international export business in this feild) |

Company Advantage

| 1, Fast response in reply 2, Good sales with reasonable price. 3, Good quality materials. 4, Fast lead time. 5, Rich experience in export business. 6, Well after sales service. 7, Flexible policy. |

Materials Workability | Easy to Weld, Cut, Form, and Machine |

Another Name | angle steel bar ,angle steel , steel angle , mild steel angle ,carbon steel bars, 304stainless steel angle bar |

Other processing service | Hot dipped Galvanized, pre-galvanized, coated, cutting, bending,punching as long as u could tell us the requirment. |

Shipment |

1, 1-10 tons it's ok to go by LCL

|

Other fittings

| Bolt with Anti-thift nut or any other required fittings (small amount order is acceptable) |

Contact

| TEL: +86-021-62153163 FAX: +86-021-62152536 (Good english speaking sales, welcome to call us if there has any questions. |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

- Q: How do steel angles compare to aluminum angles in terms of strength and durability?

- Compared to aluminum angles, steel angles exhibit superior strength and durability. This is attributed to steel's higher tensile strength and yield strength, enabling it to endure higher levels of force and pressure without warping or fracturing. Moreover, steel boasts better resistance against corrosion, ensuring its structural integrity remains intact for extended durations. In contrast, aluminum is prone to oxidation and may gradually weaken over time. Consequently, when seeking high strength and long-lasting robustness, steel angles emerge as the more favorable option over aluminum angles.

- Q: How do steel angles contribute to the overall aesthetics of a building?

- Steel angles can contribute to the overall aesthetics of a building by adding visual interest and architectural appeal. The clean lines and angular profiles of steel angles can create a modern and sleek look, enhancing the overall design of the structure. Additionally, steel angles can be used to create unique shapes and patterns, adding a sense of uniqueness and creativity to the building's appearance.

- Q: What are the different types of steel angles used in manufacturing industries?

- In manufacturing industries, there is a wide variety of steel angles utilized for different purposes. These angles possess unique characteristics that make them suitable for specific applications. 1. Unequal Leg Angles, also known as L-shaped angles, feature one longer leg and one shorter leg. They find common usage in construction and structural engineering due to their versatility. These angles offer exceptional strength and stability, making them ideal for supporting heavy loads and establishing structural connections. 2. Equal Leg Angles, also known as L-shaped angles, have both legs of equal length. They are extensively employed in manufacturing industries for diverse purposes, including bracing, framing, and supporting structures. These angles exhibit good resistance to bending and provide stable connections in various applications. 3. Stainless Steel Angles are crafted from a corrosion-resistant steel alloy, primarily comprising chromium. They possess remarkable durability, resistance to rust, and excellent strength properties. Stainless steel angles find widespread use in industries such as food processing, chemical processing, and marine manufacturing, where corrosion resistance is of utmost importance. 4. Galvanized Steel Angles are coated with a layer of zinc to safeguard them against corrosion and rust. This zinc coating ensures exceptional durability and longevity, rendering galvanized steel angles suitable for outdoor and exposed applications. They are commonly employed in industries like construction, agriculture, and transportation. 5. Rolled Steel Angles are manufactured by rolling a steel plate or sheet into the desired shape. These angles offer an excellent strength-to-weight ratio and can be produced in varied sizes and thicknesses. Rolled steel angles find extensive usage in construction, machinery, and fabrication industries for structural support and framing applications. 6. Slotted Steel Angles possess holes or slots along their length, allowing for flexibility in terms of fastening methods. They are frequently employed in shelving systems, racking, and storage solutions as they allow for easy adjustment and customization. Slotted steel angles offer versatility and convenience in manufacturing industries where quick assembly and reconfiguration are required. In summary, the assortment of steel angles utilized in manufacturing industries provides a range of properties and advantages. The choice of angle depends on the specific application, requirements for strength, corrosion resistance, and other factors that guarantee optimal performance and durability in the given application.

- Q: How do steel angles contribute to the energy efficiency of a building?

- There are multiple ways in which steel angles can enhance the energy efficiency of a building. To begin with, steel angles are commonly utilized as structural components during the construction of buildings. Their presence provides strength and support to the building's framework, enabling the incorporation of larger windows and open floor plans. This facilitates the entry of natural daylight, thereby diminishing the need for artificial lighting during the daytime and subsequently reducing energy usage. Moreover, steel angles have the ability to contribute to the creation of energy-efficient building envelopes. By integrating steel angles into the construction of walls, roofs, and floors, the occurrence of thermal bridging can be minimized. Thermal bridging refers to the escape or entry of heat in a building due to materials with high thermal conductivity, such as concrete or wood. By utilizing steel, which possesses low thermal conductivity, the transfer of heat is reduced, leading to an improvement in the overall thermal performance of the building envelope. Furthermore, steel angles can be employed for the installation of energy-conserving systems and equipment. For example, they can provide support for solar panels, which generate clean and renewable energy. Additionally, steel angles can be utilized in the installation of HVAC systems, promoting efficient air circulation and distribution throughout the building. By incorporating steel angles into these applications, the energy efficiency of the building is enhanced, resulting in decreased energy consumption and lower utility bills. To summarize, the utilization of steel angles significantly contributes to the promotion of energy efficiency in buildings. They provide structural integrity, help minimize thermal bridging, and support the installation of energy-conserving systems. By incorporating steel angles into the design and construction of a building, energy consumption is reduced, resulting in a more sustainable and cost-effective built environment.

- Q: Can steel angles be used for playground equipment?

- Yes, steel angles can be used for playground equipment. Steel angles are commonly used in the construction of playground equipment due to their strength, durability, and resistance to corrosion. They provide structural support and stability, making them ideal for ensuring the safety and longevity of playground structures.

- Q: What is the purpose of using steel angles in construction?

- Steel angles are commonly used in construction for several purposes. The primary purpose of using steel angles is to provide structural support and stability to various components of a building or structure. These angles are often used to reinforce corners, edges, and joints, adding strength and rigidity to the overall structure. Additionally, steel angles are used to distribute and transfer loads or forces within the construction. They help to evenly distribute the weight and stress across different parts of the structure, preventing any concentrated points of weakness. Moreover, steel angles are versatile and can be easily customized and fabricated to meet specific construction requirements. They can be cut, drilled, and welded, allowing for seamless integration into a wide range of construction projects. Furthermore, steel angles offer excellent durability and resistance to corrosion, making them suitable for both indoor and outdoor applications. They can withstand heavy loads, extreme weather conditions, and provide long-lasting support to the structure. In summary, the purpose of using steel angles in construction is to enhance the structural integrity, provide support and stability, distribute loads, and ensure the longevity of the building or structure.

- Q: Can steel angles be used in sports or recreational facilities?

- Yes, steel angles can be used in sports or recreational facilities. Steel angles are commonly used in the construction industry due to their strength, durability, and versatility. They are often used in the construction of sports and recreational facilities such as stadiums, arenas, gymnasiums, and indoor/outdoor courts. Steel angles are typically used to provide structural support and stability to the building. They can be used in the framing of walls, roofs, and floors, as well as in the construction of bleachers, seating areas, and staircases. Steel angles can also be used to create barriers, fences, and safety rails, ensuring the safety of athletes and spectators. In addition to their structural applications, steel angles can also be used for aesthetic purposes. They can be used as decorative elements, such as in the design of entrance gates, signage, and lighting fixtures. Steel angles can be painted or coated in various colors or finishes to match the overall design theme of the sports or recreational facility. Overall, steel angles are a versatile and practical choice for use in sports and recreational facilities. Their strength, durability, and aesthetic appeal make them suitable for a wide range of applications within these facilities.

- Q: How do you calculate the slenderness ratio of a steel angle?

- In order to find the slenderness ratio of a steel angle, one must ascertain the length and moment of inertia of the angle section. This ratio serves as a measure of the member's slenderness and aids in determining its stability and resistance to buckling. To begin, measure the length of the steel angle, which is the distance between its two ends. It is essential to use the same unit of measurement as the dimensions of the angle section. Next, compute the moment of inertia of the steel angle section. The moment of inertia, denoted as "I," quantifies the section's ability to resist bending. It relies on the dimensions of the angle section and can be obtained from reference tables or calculated through mathematical formulas. After obtaining the length and moment of inertia of the steel angle, the slenderness ratio can be calculated using the following formula: Slenderness ratio = Length of angle / √(Moment of inertia) Ensure that both the length and moment of inertia are expressed in the same unit before performing the calculation. The resulting slenderness ratio will be a dimensionless value. It is important to note that the slenderness ratio is utilized to establish appropriate design criteria and allowable loads for the steel angle. Different design codes or standards may impose specific limits or guidelines regarding the maximum slenderness ratio deemed safe for various applications. Therefore, it is crucial to consult relevant design codes or seek professional engineering advice to ensure the correct and safe utilization of the steel angle.

- Q: Can steel angles be used for artistic or decorative applications?

- Yes, steel angles can be used for artistic or decorative applications. They can be shaped, welded, or manipulated to create unique designs and structures. Their strength and durability make them suitable for various artistic projects, such as sculptures, installations, or architectural elements.

- Q: What are the considerations for selecting the appropriate steel angle thickness?

- There are several considerations for selecting the appropriate steel angle thickness. Firstly, the load-bearing capacity of the steel angle must be taken into account. The thickness should be chosen based on the expected weight and stress that will be placed on the angle. Additionally, the length and span of the angle should be considered, as longer and wider spans may require thicker steel angles to provide adequate support. Environmental factors, such as exposure to corrosive substances or extreme temperatures, should also be evaluated to select a thickness that can withstand these conditions. Finally, budget constraints and cost-effectiveness may influence the choice of steel angle thickness, as thicker angles are generally more expensive.

Send your message to us

Equal Angle Steel Cold Rolled for Constraction Application

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 28 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords