EPDM MEMBRANE or COILROOF WATERPROOF SYSTEM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 8000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

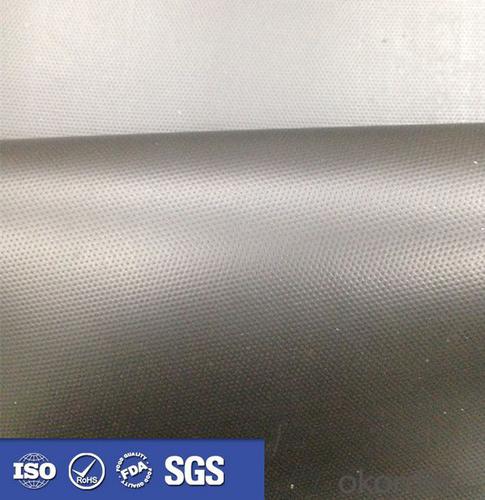

Description Of EPDM MEMBRANE or COILROOF WATERPROOF SYSTEM:

Self adhesive waterproof rolling material:

thickness:1.2/1.5/2.0mm

length/roll:10/20m

width/roll:1.02m

Low temperature:-15 -20,-30

Main Features of EPDM MEMBRANE or COILROOF WATERPROOF SYSTEM:

1) High tear

2) High puncturing strength

3) Great temperature resistance.

4) High dimensional stability

Specifications of EPDM MEMBRANE or COILROOF WATERPROOF SYSTEM:

Material | EPDM Self-adhesive Waterproof Membrane |

Size | 1.2m (width)*20m (length) or customized, weldable type 2.05m or 4m width |

Thick | 1.2mm, 1.5mm, 2.0mm |

Type | Vulcanized & Weldable |

Pattern | Non-reinforced (homogeneous) |

Certificate | ISO9001/14001 |

Applications of EPDM MEMBRANE or COILROOF WATERPROOF SYSTEM:

1.It is widely used in civil and industry construction.

2.The waterproof,dampproof of the roofs,basements,toilets etc;

3.And the waterproofing of subway,underground,bridges,car parking,tunnels,reserviors,pool etc.

4.SBS modified bitumen waterproof membrane is specially suitable to the building waterproofing in cold area and to the buildings of changeable constructions

5.APP specially suitable to areas of high temperature and of strong sunshine.

FAQ:

1. What are we supplying?

We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane, Self adhesive bitumen waterproof membrane, PVC waterproofing membrane, EPDM rubber roofing membrane, Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: Can a waterproofing membrane be used for a foundation wall damp proofing?

- Indeed, foundation wall damp proofing can be achieved by utilizing a waterproofing membrane. The purpose of a waterproofing membrane is to obstruct the flow of water, thus serving as a shield between the foundation wall and the adjacent soil. This protective shield aids in averting moisture seepage into the foundation wall, which can result in dampness and potential water harm. Through the application of a waterproofing membrane onto the foundation wall, an effective damp proofing is achieved, guarding it against water intrusion. Nevertheless, it is crucial to ensure that the installation of the waterproofing membrane is executed accurately, and that all joints and seams are adequately sealed to establish an uninterrupted barrier against water.

- Q: Can a waterproofing membrane be used on asphalt surfaces?

- Indeed, asphalt surfaces can benefit from the application of a waterproofing membrane. These membranes, widely employed in construction, are specifically engineered to safeguard against water infiltration. Their versatility allows for application on diverse surfaces, asphalt included. By applying a waterproofing membrane on an asphalt surface, one can effectively thwart water damage, prolong the surface's lifespan, and safeguard the underlying structures. It is crucial to guarantee the compatibility of the chosen waterproofing membrane with asphalt and to adhere to proper installation techniques in order to achieve the best possible outcome.

- Q: Can a waterproofing membrane be used for a balcony deck?

- Yes, a waterproofing membrane can be used for a balcony deck. In fact, it is often a recommended solution for protecting balcony decks from water damage. A waterproofing membrane is designed to create a barrier that prevents water from seeping into the underlying structure, thereby safeguarding the deck from moisture-related issues such as rot, mold, and deterioration. It is typically applied as a liquid or sheet material over the surface of the balcony deck, forming a seamless and impenetrable layer. This membrane acts as a protective shield, ensuring that any water that comes into contact with the deck is repelled and directed away. By using a waterproofing membrane, you can effectively extend the lifespan of your balcony deck and maintain its structural integrity for years to come.

- Q: Can a waterproofing membrane be used on both interior and exterior surfaces?

- Yes, a waterproofing membrane can be used on both interior and exterior surfaces. Waterproofing membranes are designed to protect surfaces from water penetration and damage. They are typically made of materials such as rubber, asphalt, or thermoplastic, which provide a barrier against moisture. Whether it is applied on interior walls, floors, or exterior foundations, roofs, or balconies, a waterproofing membrane can effectively prevent water from seeping through and causing potential issues like leaks, mold, or structural damage. It is important to consider the specific requirements of each surface and choose a waterproofing membrane that is suitable for the intended application.

- Q: Can waterproofing membranes be used on roof decks?

- Yes, waterproofing membranes can be used on roof decks. These membranes are specifically designed to provide a barrier against water penetration and protect the underlying structure from moisture damage. They are commonly used in roof deck construction to ensure a watertight and durable surface.

- Q: Are waterproofing membranes resistant to saltwater corrosion?

- Yes, waterproofing membranes are generally resistant to saltwater corrosion. They are designed to withstand harsh environmental conditions, including exposure to saltwater, without deteriorating or being affected by corrosion.

- Q: Can a waterproofing membrane be used on below-grade walls?

- Indeed, a waterproofing membrane is capable of being employed on walls located below ground level. In fact, it is highly advisable to utilize a waterproofing membrane on such walls so as to shield them against infiltration of water and potential harm caused by moisture. Walls situated below ground level are especially susceptible to water penetration due to their proximity to the ground and the possibility of hydrostatic pressure. A waterproofing membrane serves as a protective barrier, effectively preventing water from seeping into the walls and leading to issues such as mold, mildew, decay, and structural impairment. Moreover, it aids in maintaining the interior of the edifice in a dry condition, thereby averting potential problems related to moisture.

- Q: How does a waterproofing membrane perform in areas with heavy foot traffic?

- A waterproofing membrane performs well in areas with heavy foot traffic as it is designed to withstand constant use and provide durable protection against water intrusion. It acts as a barrier, preventing water from seeping through the surface and damaging the underlying structures. Additionally, many waterproofing membranes are designed to be slip-resistant, ensuring safety for pedestrians even in high-traffic areas.

- Q: How does a waterproofing membrane handle settlement of adjacent structures?

- A waterproofing membrane is designed to handle settlement of adjacent structures in a few different ways. Firstly, a high-quality waterproofing membrane is often flexible and elastic, allowing it to stretch and move with the settling of the adjacent structures. This flexibility helps to prevent the membrane from cracking or tearing under the stress of settlement. Additionally, some waterproofing membranes are reinforced with materials such as fiberglass or polyester to provide added strength and durability. These reinforcements help to distribute the stress caused by settlement more evenly across the membrane, reducing the likelihood of damage. Furthermore, waterproofing membranes are typically applied in multiple layers to provide redundancy and added protection. This means that even if one layer of the membrane is compromised due to settlement, there are additional layers underneath that can continue to provide waterproofing. Lastly, proper installation and maintenance of the waterproofing membrane is crucial in ensuring its ability to handle settlement. A skilled contractor will take into account the potential for settlement and will properly prepare the substrate and apply the membrane to minimize the risk of damage. In summary, a waterproofing membrane can handle settlement of adjacent structures through its flexibility, reinforcements, multiple layers, and proper installation. These features work together to ensure that the membrane remains intact and continues to provide effective waterproofing, even in the presence of settlement.

- Q: Can a waterproofing membrane be used in bridge decks or roadways?

- Yes, bridge decks and roadways can benefit from the use of a waterproofing membrane. This protective layer prevents water infiltration and increases the lifespan of the structure. Given the harsh weather conditions and heavy traffic that bridge decks and roadways face, a waterproofing membrane is essential. Water penetration can cause damage to bridge decks and roadways, including corrosion of steel reinforcements and deterioration of concrete. By applying a waterproofing membrane, a barrier is created to prevent water from seeping into the structural elements. This reduces the risk of corrosion and extends the durability of the bridge or roadway. Additionally, a waterproofing membrane can help prevent the formation of cracks and potholes, which are often caused by the freeze-thaw cycle and water penetration. By keeping the surface of the bridge deck or roadway dry, the membrane maintains its structural integrity and avoids costly repairs or premature replacement. It is important to consider factors such as material selection, installation techniques, and maintenance when using a waterproofing membrane in bridge decks or roadways. The chosen membrane should be compatible with the construction materials, and the installation process must be done correctly to ensure a watertight seal. Regular maintenance and inspections should also be done to identify any issues or damage to the membrane. This allows for timely repairs and ensures its effectiveness over time. Overall, using a waterproofing membrane in bridge decks or roadways is an efficient solution to protect against water damage and extend the lifespan of these critical infrastructure elements.

Send your message to us

EPDM MEMBRANE or COILROOF WATERPROOF SYSTEM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 8000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords